Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 15, 2025

Flavor Lab GC-MS Analysis

When consumers choose a food or beverage product, flavor consistency is one of the strongest determinants of satisfaction and repeat purchase. No matter how innovative or healthy a formulation may be, a single off-note — a faint rancid, stale, or oxidized aroma — can lead to instant consumer rejection.

This challenge arises from the inherent instability of volatile compounds, the molecules responsible for aroma and taste perception. These compounds are chemically active and prone to oxidation, hydrolysis, polymerization, or evaporation, which can alter sensory quality during processing, storage, or transportation.

As a professional manufacturer of food and beverage flavorings, we at CUIGUAI Flavoring focus on stabilizing volatile components to maintain flavor fidelity from formulation to final consumption. In this article, we will explore the science, mechanisms, and practical strategies behind protecting taste integrity — empowering R&D professionals and manufacturers to optimize product stability and consumer appeal.

Volatile compounds are organic molecules that readily evaporate at room temperature and contribute directly to a product’s aroma and retronasal taste. In the food and beverage industry, hundreds of such compounds can define a single flavor profile — from esters and aldehydes in fruity notes to terpenes, lactones, and pyrazines in natural extracts.

| Compound Type | Typical Role | Common Examples |

| Esters | Fruity, sweet aroma | Ethyl butyrate, isoamyl acetate |

| Aldehydes | Green, citrusy, fatty notes | Hexanal, citral, benzaldehyde |

| Ketones | Creamy, buttery tones | Diacetyl, acetoin |

| Terpenes | Floral, herbal, citrus | Limonene, linalool, myrcene |

| Lactones | Milky, coconut, peach notes | γ-Decalactone, δ-Octalactone |

| Sulfur compounds | Savory or meaty impact | Dimethyl sulfide, methional |

Each of these volatile molecules has unique sensitivity to heat, light, oxygen, pH, and matrix interactions.

For example, limonene, a key component in citrus flavors, is extremely prone to oxidation, producing off-odor compounds such as carveol or carvone (Journal of Agricultural and Food Chemistry, 2017). Similarly, aldehydes like hexanal rapidly form carboxylic acids under aerobic conditions, altering aroma intensity.

Thus, controlling volatility and reactivity is the cornerstone of maintaining long-term flavor integrity.

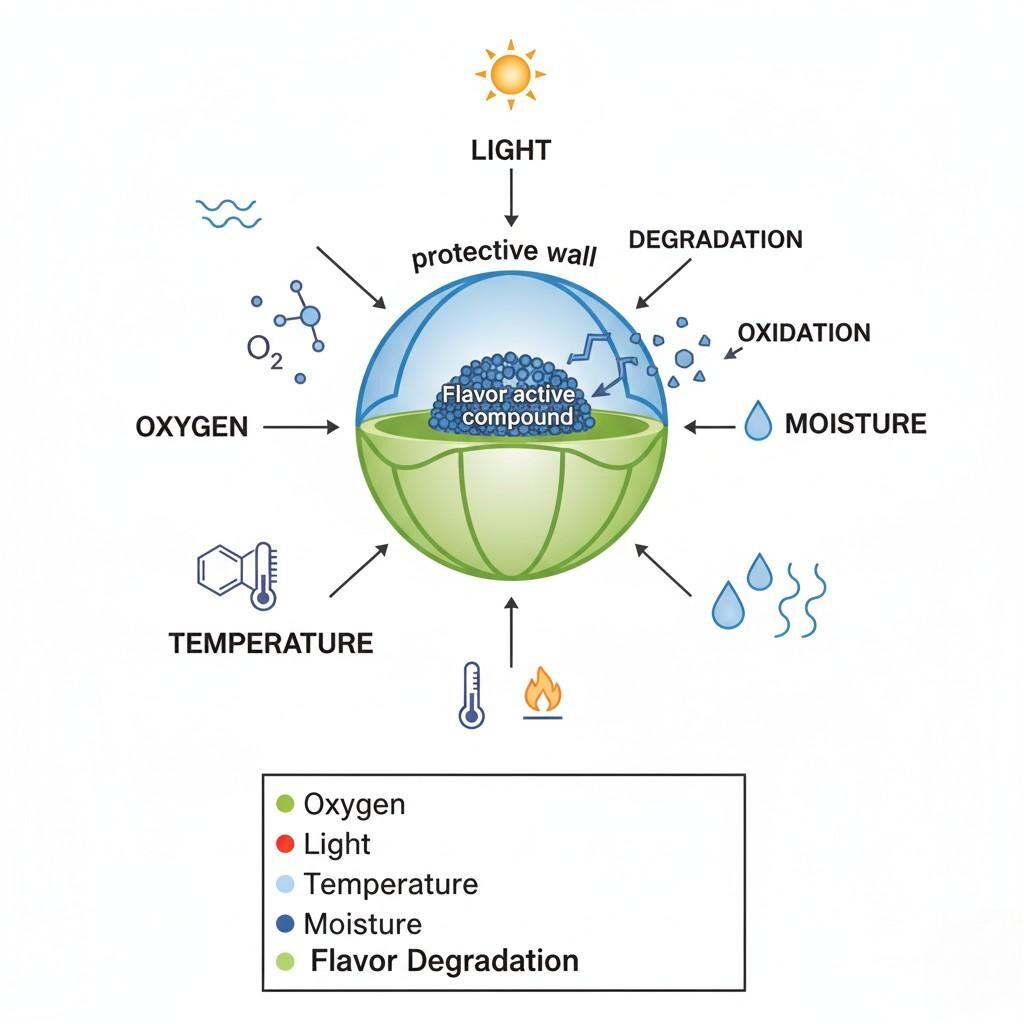

Oxidation is the primary degradation pathway for most flavor systems. It occurs when volatile molecules interact with oxygen, light, or transition metals such as iron and copper.

The oxidation of flavor molecules can result in:

Aldehydes and terpenes are particularly vulnerable. For example, d-limonene oxidation can be initiated by trace peroxides, leading to peroxyl radicals that accelerate further degradation.

According to the U.S. National Library of Medicine (PubChem), oxidative reactions in volatile organics can begin at concentrations below 1 ppm of reactive oxygen species, emphasizing the extreme sensitivity of these molecules (source).

Flavor esters such as ethyl acetate and butyl butyrate can undergo hydrolysis in the presence of moisture, heat, or low/high pH. The result is the breakdown into acid and alcohol, reducing sweetness and fruity aroma.

Proteins, carbohydrates, and lipids in the product matrix can absorb or bind flavor molecules. For instance, starch-based snacks may trap volatile esters within gelatinized regions, diminishing perceived aroma. Beverage emulsions, on the other hand, can lose top notes through phase separation or creaming if improperly stabilized.

These mechanisms make it clear: flavor chemistry and food formulation are inseparable disciplines.

Flavor Degradation Factors Diagram

Heat accelerates reaction kinetics, doubling oxidation rates for every 10°C rise. This means storage at 35°C may cause four times faster aroma loss compared to 25°C. Thermal processing such as pasteurization, baking, or spray-drying must therefore be carefully optimized.

Ultraviolet and visible light can trigger photooxidation. Compounds like riboflavin (in dairy products) act as photosensitizers, generating singlet oxygen that attacks terpenes and aldehydes. Packaging with UV filters or opaque containers can dramatically improve flavor shelf life.

Even trace oxygen in packaging can cause gradual oxidation. The oxygen transmission rate (OTR) of packaging materials plays a crucial role. High-barrier films such as EVOH or metalized PET are often preferred for sensitive flavors.

The Institute of Food Technologists (IFT) highlights that optimizing oxygen barriers can extend flavor stability in ready-to-drink beverages by up to 200% (IFT.org).

A pH below 3 (acidic drinks) or above 8 (alkaline systems) can catalyze hydrolysis. Similarly, water activity influences molecular mobility — too low and the system becomes rigid (reducing diffusion), too high and oxidation increases. Balancing aw between 0.3–0.6 often achieves optimal stability.

Flavors shipped through hot, humid environments face higher volatility losses. Insulated transport and nitrogen-flushed containers can mitigate degradation.

GC–MS remains the gold standard for identifying and quantifying volatile compounds. It enables precise monitoring of molecular changes over time, helping to determine degradation pathways.

Solid-phase microextraction (SPME) coupled with GC–MS measures volatile concentration in the headspace above a sample, simulating the human aroma perception experience. This method is particularly useful for evaluating shelf-life aroma loss.

Trained sensory evaluation complements instrumental data, while electronic noses can provide objective, rapid assessments of flavor freshness.

The University of California, Davis Department of Food Science notes that combining sensory and instrumental data offers the most reliable measure of flavor retention during shelf life (UC Davis Food Science).

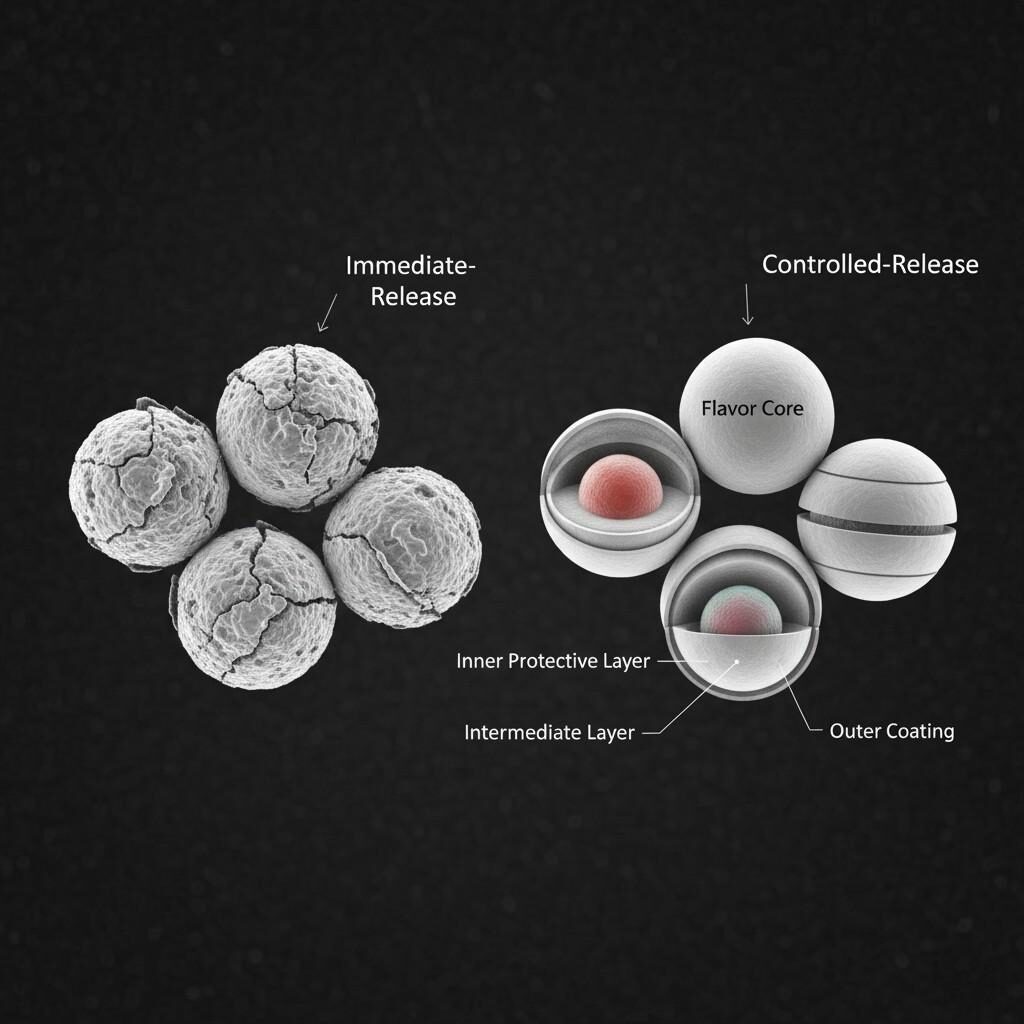

Microencapsulated Flavor Comparison

Antioxidants such as tocopherols, ascorbyl palmitate, and rosemary extract inhibit free radical chain reactions. Oxygen scavengers like iron-based sachets or ascorbic acid derivatives further reduce residual oxygen in packaging.

Microencapsulation remains the most effective technique to protect volatile compounds. By surrounding flavor oils in a protective matrix (gum arabic, modified starch, maltodextrin, etc.), it:

Encapsulation methods include:

According to a review published in Trends in Food Science & Technology (Elsevier, 2020), encapsulation can reduce aroma compound loss by up to 80% compared with non-encapsulated systems.

For liquid flavors, emulsifiers (gum acacia, modified starch, sucrose esters) help stabilize oil droplets. Adding weighting agents like ester gum or sucrose acetate isobutyrate ensures even dispersion and visual clarity in the beverage.

Chelators such as citric acid or EDTA bind trace metals that catalyze oxidation. This step is especially important in fruit-based drinks and dairy systems.

Using nitrogen flushing, vacuum sealing, and UV-protected multilayer films significantly extends flavor stability. Smart packaging with oxygen indicators helps monitor degradation in real time.

A beverage producer experienced aroma fading in a citrus drink within 60 days. GC–MS analysis showed oxidation of limonene and loss of aldehydes.

CUIGUAI Flavoring developed a stabilized citrus system using:

After 6 months at 25°C, flavor retention improved by 82%, and no off-notes were detected in sensory testing. This validated the synergistic benefit of combining formulation chemistry + packaging science.

Flavor stability efforts must align with food safety regulations such as:

All encapsulation materials, antioxidants, and chelating agents must be food-grade and GRAS-certified.

As per the FDA’s Food Additive Status List, only certified GRAS components (like tocopherols and gum arabic) are permitted for flavor stabilization in foods (FDA.gov).

Looking ahead, R&D trends in flavor technology are focusing on sustainable and intelligent delivery systems:

At CUIGUAI Flavoring, we continue to invest in these frontiers — integrating molecular-level control with sensory-driven design to protect and enhance flavor identity.

FlavorSeal Product Lineup

Flavor stability is not just a formulation parameter — it’s a critical quality promise to consumers. Understanding volatile compound behavior, employing smart stabilization strategies, and choosing high-quality flavor ingredients make all the difference between short-term novelty and long-term market success.

With advanced techniques in oxidation control, encapsulation, and packaging, manufacturers can preserve taste integrity from factory to fork — or bottle to glass.

At CUIGUAI Flavoring, our R&D team partners with food and beverage brands to develop custom flavor systems that resist degradation, optimize sensory longevity, and uphold brand reputation.

If you’re developing a new beverage, snack, or dairy formulation and need technical guidance or free stabilized flavor samples, contact CUIGUAI Flavoring today.

👉 Request a consultation or sample:

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.cn]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.