Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 25, 2025

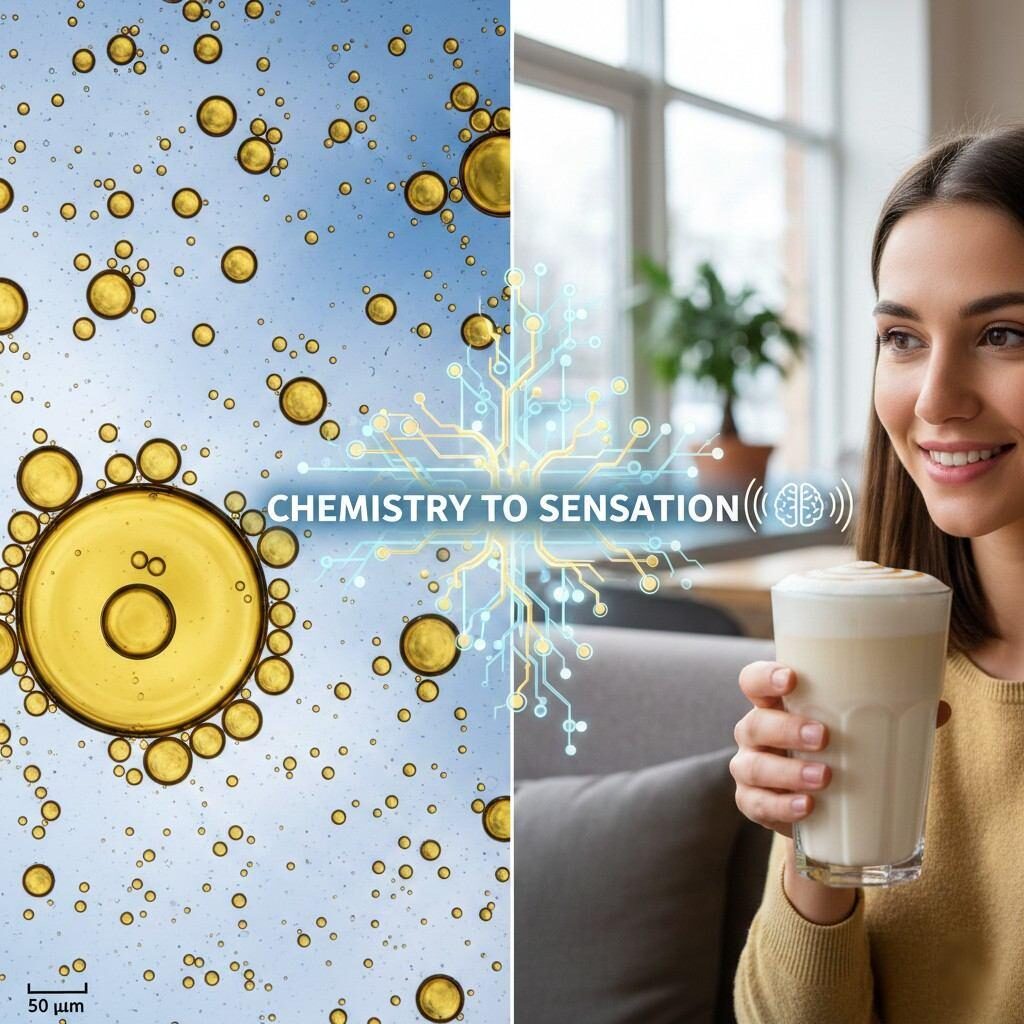

Emulsion to Sensation

In the complex architecture of food and beverage formulation, flavor is often hailed as the king. It is the immediate hook, the signature identity of a product. However, if flavor is the king, mouthfeel is the throne upon which it sits. Without the structural integrity of a pleasing texture, even the most exquisite flavor profile will fail to resonate with the consumer.

For food scientists and product developers, the current market landscape presents a paradox. Consumers demand “free-from” products—low sugar, low fat, dairy-free, and gluten-free—yet they refuse to compromise on the indulgence, creaminess, and body associated with traditional full-calorie formulations. When you remove functional ingredients like sucrose or milk fat, you strip away the product’s physical structure, resulting in beverages that feel “thin” or dairy alternatives that feel “chalky.”

As a professional manufacturer of food and beverage flavorings, we understand that texture is not just a physical property; it is a multisensory perception. It is the bridge between the chemistry of your ingredients and the hedonistic satisfaction of your customer. This article delves into the technical science of mouthfeel, the physiology of texture perception, and how expert flavor solutions can restore, enhance, and optimize the tactile experience of your products.

To solve texture challenges, we must first understand how the human body perceives it. Mouthfeel is not detected by the gustatory system (taste buds) but rather by the somatosensory system. This involves a complex interplay of three primary mechanisms:

When a consumer describes a product as “watery,” “gritty,” or “slimy,” they are reporting a failure in one of these physiological interactions.

According to research published by the National Institutes of Health (NIH), texture perception is a dynamic process that changes from the moment food enters the mouth (initial viscosity) to the moment it is swallowed (bolus formation and coating). A successful formulation must address the entire temporal experience, not just the initial sip [1].

The modern clean-label movement has unintentionally waged war on mouthfeel. The removal of traditional bulking agents creates sensory voids that are difficult to fill with hydrocolloids (gums and starches) alone.

Sucrose provides more than sweetness; it provides solids. In a beverage, sugar contributes to the “body” and viscosity. Replacing 10g of sugar with milligrams of high-intensity sweetener (like Stevia or Sucralose) results in a dramatic drop in dissolved solids. The result is a beverage that tastes sweet but feels “hollow” or “empty” in the mid-palate.

Fat is the gold standard for lubricity. It coats the oral cavity, masking off-notes and carrying flavor compounds to the olfactory receptors over a sustained period. Removing fat creates a high-friction environment in the mouth, often described as “dry” or “dragging.”

Plant proteins (pea, soy, rice) have larger particle sizes and different solubility profiles than dairy proteins (casein, whey). This often leads to:

While gums, starches, and stabilizers are the traditional tools for adjusting viscosity (rheology), they often fail to address lubricity (tribology). This is where expert flavor solutions come into play.

Advanced flavor technology allows us to use flavor modulation to trick the brain’s cross-modal perception. By utilizing specific volatile and non-volatile compounds, we can trigger the sensation of thickness, creaminess, or coating without actually adding solids or fats.

Flavor Science & Rheology

We utilize specific flavor compounds, such as lactones (which provide creamy, coconut-like, or buttery notes) and vanillin derivatives, which have been proven to enhance the perception of creaminess.

However, true innovation lies in chemesthesis. We develop proprietary mouthfeel enhancers that interact with the mechanoreceptors on the tongue to simulate the “slip” and “slide” of fat. These solutions are particularly effective in:

Beyond umami lies Kokumi. Derived from the Japanese word for “rich” or “hearty,” Kokumi substances (often gamma-glutamyl peptides) do not have a taste of their own but dramatically enhance the complexity, mouthfeel, and lingering coating sensation of a food.

Incorporating Kokumi-active flavor solutions into savory broths, low-sodium sauces, or even low-fat dairy products can extend the “hang time” of the flavor, making a thin liquid feel substantial and satisfying.

To combat the “hollow” feeling of sugar-free beverages, we employ flavor modulators that enhance the perception of body. These compounds work synergistically with sweeteners to round out the flavor profile.

For example, specific maltol compounds can add a “jammy” or “syrupy” sensation that tricks the brain into perceiving a higher viscosity. This concept is supported by research from the Monell Chemical Senses Center, which highlights how odor-taste interactions (like vanilla smelling sweet and creamy) can alter the perceived texture of a product [2].

As a manufacturer, we tailor our texture solutions to the specific matrix of your product. Here is how we approach key categories:

In plant-based dairy alternatives, texture and flavor are inextricably linked. The “beany” or “green” notes of pea protein can accentuate the perception of astringency.

Plant Milk Comparison

In the booming Ready-to-Drink (RTD) and hard seltzer market, consumers want high flavor impact with low calories. However, alcohol contributes to mouthfeel. Removing sugar and lowering alcohol content (in low-ABV drinks) results in a watery product.

In low-fat baked goods, the biggest complaint is dryness.

Creating a mouthfeel flavor solution is not simple mixing; it is precision engineering. At our manufacturing facility, we employ a rigorous R&D process:

This data-driven approach ensures that our flavor solutions perform consistently in your manufacturing environment, surviving shear, heat pasteurization, and shelf-life storage.

We understand that “Mouthfeel Enhancer” is not a friendly term for an ingredient deck. Today’s consumers read labels.

The beauty of our flavor solutions is that they are typically categorized as “Natural Flavors” under regulatory frameworks. This allows you to improve the texture of your product without adding gums, starches, or emulsifiers that might clutter your label or trigger consumer concern regarding processed ingredients.

As outlined by the Flavor and Extract Manufacturers Association (FEMA), the safety and specification of flavor ingredients are rigorously maintained, ensuring that functional flavor solutions meet global safety standards while delivering necessary sensory attributes [4].

The era of compromising texture for health is over. Consumers expect their protein shake to be smooth, their sugar-free soda to have body, and their vegan cheese to melt and coat the palate.

Mouthfeel is the silent salesman. It is the attribute that determines whether a product feels “premium” or “cheap.” By integrating expert flavor solutions that target rheology and tribology, manufacturers can bridge the gap between nutritional goals and sensory indulgence.

As your partner in flavor innovation, we are dedicated to solving the invisible challenges of formulation. We don’t just sell flavors; we engineer experiences.

R&D Collaboration

Are you struggling with a “thin” beverage, a “dry” bakery product, or a “chalky” protein shake? Don’t let poor mouthfeel compromise your product launch.

Partner with us to unlock the full potential of your formulation.

Contact Us Today:

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.cn]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.