Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 10, 2026

Plant-Based Protein Transformation

The plant-based protein market is undergoing an unprecedented expansion, shifting from a niche dietary category to a global, mainstream movement driven by critical societal shifts. As consumers prioritize sustainability, reduce red meat consumption due to health concerns, and seek ethical food choices, the market for plant-based alternatives—spanning meat, dairy, and seafood—is soaring. The total market value, projected to climb from approximately $20.33 billion in 2025 to over $43.07 billion by 2034 [3.1, 3.4], underscores the immense commercial opportunity. This trajectory is contingent, however, on a single, non-negotiable factor: taste parity.

The industry’s technical challenge is profound. Plant protein isolates (PPIs) derived from sources like pea, soy, rice, and faba bean are the structural foundations of these products, yet they carry inherent sensory liabilities. These off-notes—predominantly bitterness, beany/leguminous aromas, and textural astringency—are chemical markers that trigger avoidance behavior in consumers, even when the product texture is near-perfect. The lingering metallic or earthy aftertaste often destroys the perceived quality and undermines the significant investment made in texture engineering and nutritional fortification [4.2].

For professional flavor manufacturers, this represents the most complex flavor challenge of the current era. It is insufficient to merely mask the negative flavors; a more sophisticated, multi-disciplinary approach is required. We must design a comprehensive multi-pronged flavor architecture strategy that simultaneously achieves three vital objectives:

This extensive technical discourse provides an authoritative, detailed exploration of the molecular causes of plant protein bitterness and the cutting-edge, science-backed flavor solutions required to unlock the full potential of the alternative meat and dairy market, driving repeat consumer purchases and securing brand loyalty.

Effective flavor correction begins with a precise molecular diagnosis of the raw protein material. Different plant protein sources, and even different processing batches from the same source, present unique off-note profiles. Identifying these specific chemical culprits is essential, utilizing advanced analytical techniques such as Gas Chromatography-Mass Spectrometry (GC-MS) for volatile compounds and High-Performance Liquid Chromatography (HPLC-MS) for non-volatile components like peptides and saponins [2.3].

Pea protein isolate (PPI) is a market leader, projected to exceed $13.78 billion by 2034 [3.1]. Its high protein content (typically >80%) and non-allergenic status (relative to soy) make it ideal, yet it carries significant flavor liabilities.

The core challenge of PPI is its inherent, non-volatile bitterness, which is difficult to remove through simple aroma masking:

The recognizable “beany” or “cardboard” aroma is primarily an oxidative defect, driven by volatile carbonyl compounds:

Soy protein isolate (SPI) is a highly functional and economical protein source. While advancements have reduced its traditional “soy milk” flavor, two issues persist:

The industry consensus is clear: masking alone is an outdated, ineffective strategy. Instead, we employ a sophisticated Triple-Action Flavor Architecture that chemically intervenes at the source of the off-note while simultaneously building an authentic savory profile [4.1].

The most advanced flavor solutions work at the sensory level, actively deactivating the bitter signal rather than merely covering it up.

We utilize proprietary, clean-label flavor modulators—natural compounds often derived from highly purified botanical extracts or specific peptides. These are engineered to precisely interact with the TAS2R bitter receptors (of which humans have 25) on the tongue.

To counter the binding effects of polyphenols:

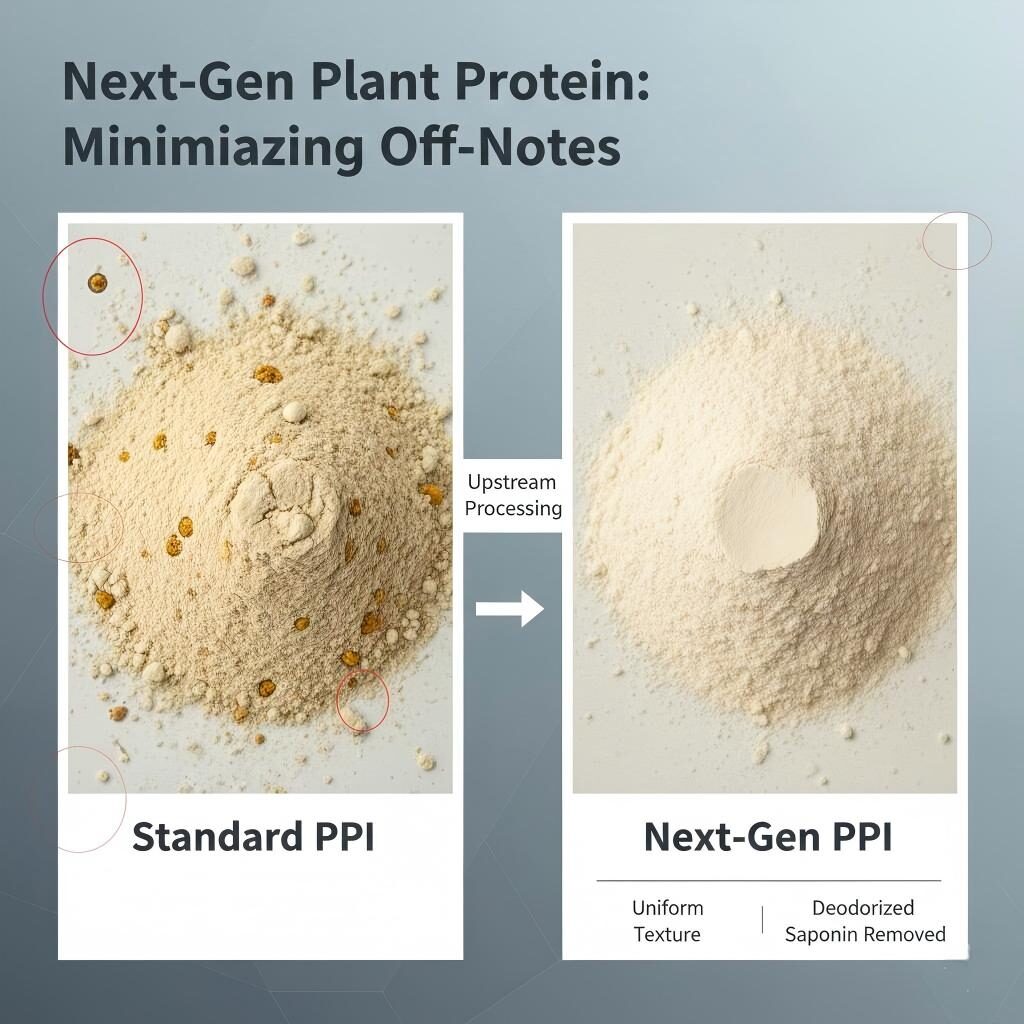

Protein Isolate Quality Comparison

Once the core bitterness is neutralized, targeted masking addresses the residual volatile aromas (beany, earthy). The goal is integration, not suppression.

| Off-Note Profile | Flavor Masking Agent Category | Technical Formulation Strategy |

| Beany/Earthy Volatiles (Hexanal, Octanal) | Alliaceous & Culinary Typified Solutions | Formulation with concentrated, heat-stable, and natural extracts of onion, garlic, mushroom, and slow-roasted vegetables. These flavors provide a rich, kitchen-like savory base whose intrinsic volatile profile effectively integrates and overpowers the undesirable cereal and vegetable notes [2.1]. |

| Residual Bitterness/Aftertaste | High-Umami Yeast Extracts & Process Flavors | Utilizing autolyzed or hydrolyzed yeast extracts that are rich in nucleotides and free glutamates. These compounds, while providing umami, also possess a powerful rounding effect on lingering off-notes, creating a smooth, brothy finish that prevents the resurgence of bitterness in the aftertaste [2.2, 2.4]. |

| Metallic Notes (from mineral fortification) | Natural Chelating Agents | Incorporating natural food acids (e.g., specific citric acid salts) and certain amino acid profiles that possess high binding affinity for metal ions (Fe2+, Zn2+). This chelation prevents the free ions from interacting with the taste receptors, effectively neutralizing the metallic flavor [2.2]. |

Replacing animal protein means rebuilding the complex savory profile that the consumer associates with “meatiness.”

Animal muscle protein, fat, and sugars create thousands of unique flavor compounds upon cooking (the Maillard Reaction). Plant proteins inherently lack the necessary ratios of specific amino acid precursors (especially sulfur-containing amino acids) and fats.

Animal fat is a critical flavor carrier and determinant of mouthfeel. Replacing it with often-solid plant oils (like coconut or shea butter) can lead to a waxy, dry texture, which amplifies off-notes.

Achieving plant-based perfection demands a collaborative approach that extends beyond the flavor vial. Success requires technical synergy across the entire product development lifecycle.

The most cost-effective way to manage off-notes is to minimize them at the raw material stage. We collaborate closely with protein suppliers to influence and leverage advanced protein processing techniques:

In alternative meats, texture and flavor are functionally inseparable. Poor texture amplifies flavor defects, while superior texture minimizes their perception.

The plant-based consumer is highly health and ethically conscious, demanding clean-label and recognizable ingredients. Every flavor component used in neutralization, masking, and authentication must meet strict clean-label standards. This reinforces the need for natural extracts, non-GMO status, and transparent ingredient sourcing. Our commitment to Green Chemistry ensures our flavor solutions support the client’s promise of purity and health, which is critical for driving the premium pricing often seen in this category.

The $43-billion-dollar opportunity in the plant-based protein market rests squarely on the shoulders of the flavor technologist. The consumer has made the conscious choice to buy alternative meats, but they will not compromise on the expectation of a delicious, authentic eating experience.

The challenge of stabilizing lipid-based volatiles, neutralizing bitter peptides, and constructing complex Maillard profiles from scratch is precisely the frontier of modern food science. We have demonstrated that addressing the triple threat of bitterness, beany aroma, and astringency requires moving beyond outdated “masking” techniques to a precision-engineered Triple-Action Flavor Architecture. This comprehensive strategy—combining molecular neutralization, clean-label integration, and authentic savory construction—is the key to eliminating off-notes and transforming challenging plant protein bases into irresistible, craveable products.

By integrating advanced analytical chemistry, sensory science, and proprietary flavor synthesis, we enable our clients to achieve taste parity and secure their market leadership in this rapidly evolving, high-stakes segment.

Collaborative Sensory Testing Team

Don’t let the bitterness of plant proteins limit your product’s success. Partner with our R&D experts to design a customized, clean-label flavor architecture that guarantees taste acceptance and repeat purchase.

Request a Technical Exchange to Address Bitterness or Request a Free Sample Kit of Our Advanced Bitter Masking Solutions

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.