Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 09, 2025

Flavor Chemistry Lab: GC-MS Analysis of Natural Extracts

In the modern food and beverage industry, innovation is no longer optional—it’s a strategic imperative. Consumers today demand more than taste; they seek health, sustainability, and novelty in every bite or sip. As a result, investing in flavor innovation has become one of the most rewarding long-term strategies for food manufacturers.

According to a report from McKinsey & Company (2023), companies that consistently invest in product and ingredient innovation outperform competitors by up to 30% in market share growth within five years. Among these, flavor innovation stands out as the most direct way to connect with consumers’ sensory expectations and emotional satisfaction.

This article explores why allocating resources to flavor R&D—especially through partnerships with professional flavor manufacturers—pays off economically, technically, and strategically.

Global consumer behavior is shifting toward products that balance taste, health, and experience. Reports from Mintel (2024) reveal that 67% of consumers are willing to pay more for food and drinks with “unique” or “natural” flavor experiences. This signals an opportunity for manufacturers to capture higher margins through differentiated flavor design.

Flavor is now not only a sensory factor—it’s a brand identity driver. A distinctive flavor can anchor a product’s emotional connection with customers, increasing repeat purchase rates and long-term loyalty. For instance, iconic products like Coca-Cola or Lay’s owe much of their success to proprietary flavor formulas that are nearly impossible to replicate.

Innovation in flavor development creates a sustainable competitive advantage. Unlike packaging or marketing, a unique flavor formula cannot easily be copied without significant R&D investment.

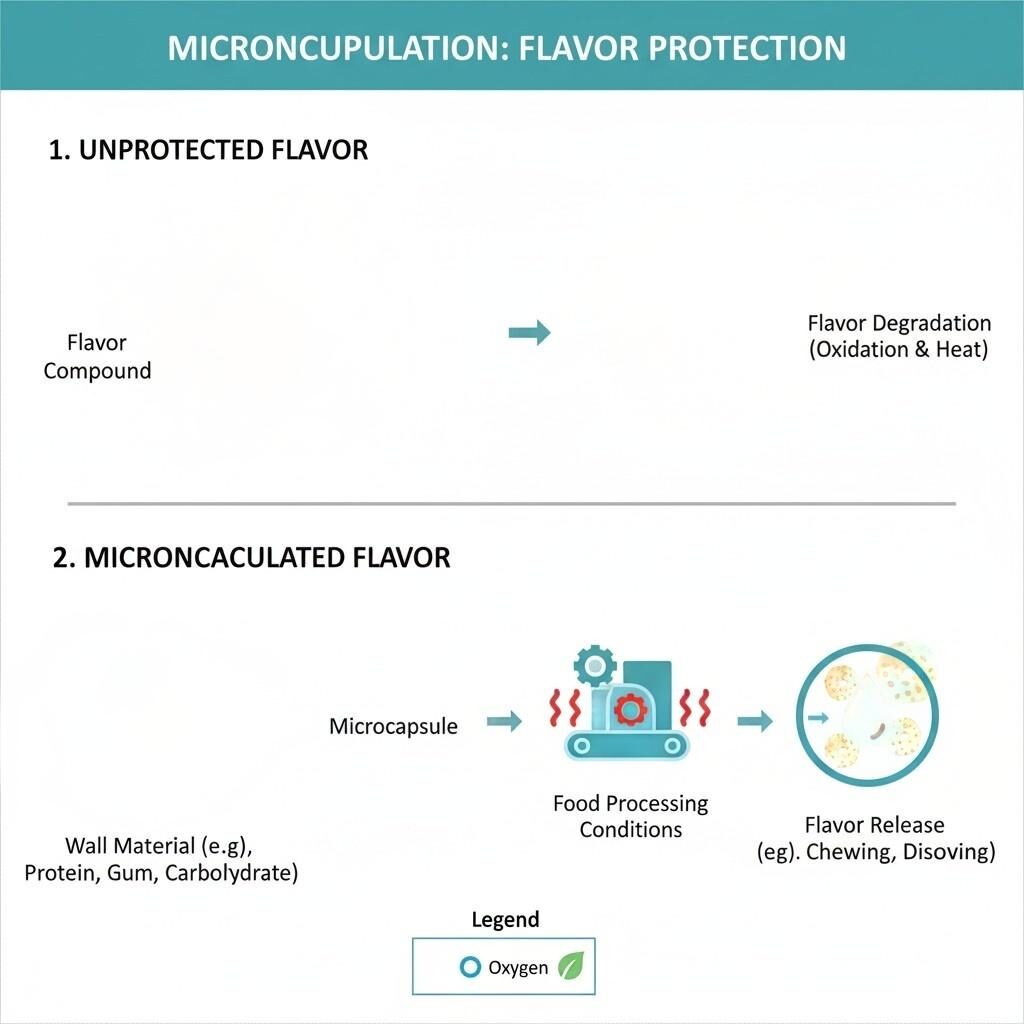

Manufacturers that invest early in flavor technology—such as microencapsulation, flavor layering, and controlled-release systems—can extend shelf life, improve heat stability, and optimize sensory delivery, ultimately reducing production costs and waste.

Microencapsulation: Protecting Flavors from Oxidation and Heat

Advances in GC–MS (Gas Chromatography–Mass Spectrometry) and AI-driven formulation tools are reshaping how flavors are developed. These technologies allow precise analysis of aroma compounds and their interactions, leading to data-based optimization rather than trial-and-error formulation.

By analyzing volatile profiles, scientists can map sensory perception to molecular structures, creating more targeted and consistent flavors. This process enhances both efficiency and product reproducibility, key concerns in large-scale food manufacturing.

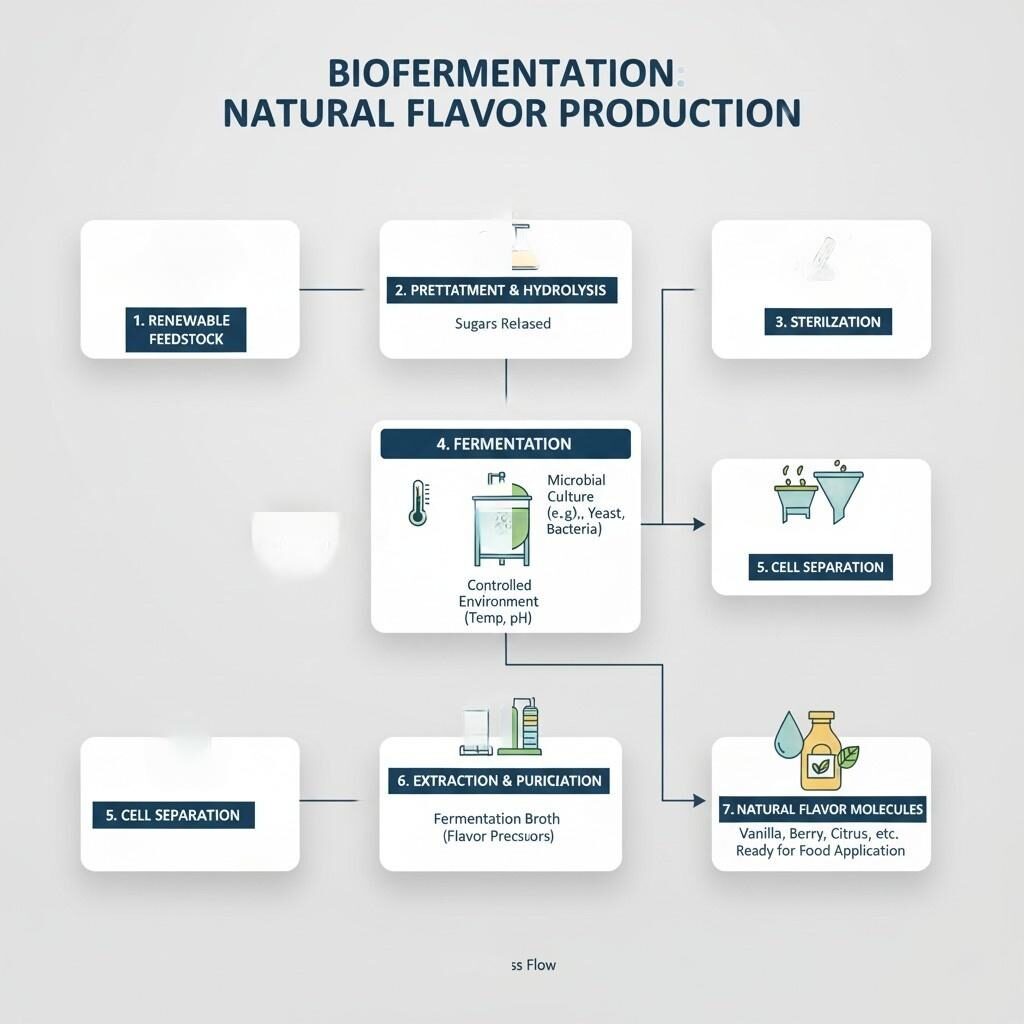

The demand for natural flavor extracts—from botanicals, fruits, and fermentation-derived sources—continues to grow. Consumers increasingly associate natural flavors with safety and premium quality. However, natural sourcing introduces challenges like supply instability and oxidation susceptibility.

Innovative manufacturers are now using biofermentation and enzymatic synthesis to replicate natural molecules more sustainably. According to the U.S. Department of Agriculture (USDA), bio-based flavor compounds can reduce environmental impact by up to 40% compared to conventional extraction methods (source: USDA BioPreferred Program, 2023).

Biofermentation Flowchart: Natural Flavor Molecule Production

One of the most promising trends is functional flavor innovation—flavors designed not only to enhance taste but also to deliver added physiological or psychological benefits.

Examples include:

Research from the Journal of Food Science (2022) demonstrates that consumers perceive flavored products with a functional claim as 25–40% more valuable than their standard counterparts. This has driven global investment in “flavor + function” formulation strategies.

At first glance, investing in flavor R&D may appear costly. However, modern flavor technologies actually reduce long-term operational costs by improving formulation efficiency and minimizing wastage.

For instance:

Studies from Food Business News (2024) indicate that every $1 invested in flavor process innovation yields $3–$5 in product-level returns through improved stability and brand differentiation.

A signature flavor can become a company’s most valuable intellectual property asset. Proprietary flavor systems are often trademarked or patented, allowing manufacturers to build brand equity that endures for decades.

Moreover, flavor innovation supports product line diversification—from dairy to plant-based beverages to snack coatings—helping brands enter new markets with reduced development time.

By partnering with a professional flavor manufacturer equipped with analytical and sensory evaluation tools, food producers can dramatically shorten the R&D cycle.

Advanced testing protocols (GC–MS, GC–Olfactometry, and sensory panels) allow precise iteration, cutting product development time by up to 50% compared to conventional trial methods.

This agility not only enhances competitiveness but also supports faster response to market trends, such as seasonal flavors, low-sugar beverages, or ethnic fusion foods.

Flavor innovation is both a science and an art. To achieve consistent results at industrial scale, manufacturers often collaborate with specialized flavor houses that combine chemical expertise, sensory analytics, and regulatory compliance knowledge.

Partnering with a professional flavor supplier ensures:

CUIGUAI Flavoring, for instance, integrates GC–MS aroma profiling, functional flavor design, and natural extraction expertise, helping clients in food and beverage industries accelerate innovation while maintaining safety and consistency.

Flavor innovation must comply with increasingly complex global standards. Regulations such as the European Food Safety Authority (EFSA) Flavouring Regulation (EC) No 1334/2008 and U.S. FDA 21 CFR 172.515 define permissible flavor substances, purity criteria, and labeling requirements.

Professional flavor manufacturers help clients navigate these frameworks, ensuring that new products remain compliant without compromising on sensory performance or marketability.

Global Flavor Regulatory Standards Comparison: EU, USA, China

Investors are increasingly drawn to companies demonstrating strong innovation pipelines. According to Forbes (2023), R&D investment in food technology is among the top five indicators of long-term brand valuation growth. Flavor innovation serves as a tangible representation of this strategic capability—demonstrating that a company can anticipate market trends and execute efficiently.

With rising competition and shrinking margins, sustainable differentiation is the key to survival. While packaging and marketing can be replicated, authentic flavor experiences cannot.

By developing proprietary flavor technologies—especially those aligned with clean label, plant-based, or functional trends—companies secure a unique market position that competitors find difficult to imitate.

Modern flavor innovation integrates AI, machine learning, and big data to predict consumer preferences before launch. By analyzing historical flavor data, social media trends, and cultural taste shifts, food manufacturers can forecast winning combinations ahead of competitors.

This predictive capability transforms flavor development from a creative process into a data-backed growth engine.

Investing in flavor innovation is more than an R&D expense—it’s a strategic investment in sensory identity, market differentiation, and long-term profitability.

From natural extraction and functional flavor design to AI-driven sensory mapping, the technologies available today empower manufacturers to turn taste into a measurable business advantage.

Whether developing new plant-based beverages, health-oriented snacks, or traditional products with modern appeal, forward-thinking companies are discovering that the ROI of flavor innovation extends far beyond the lab—into market share, brand loyalty, and consumer trust.

If your company is ready to explore innovative, natural, and functional flavor solutions, we invite you to connect with our technical team at CUIGUAI Flavoring.

📧 Contact us today to start your flavor innovation journey.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.cn】

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.