Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 19, 2026

Science-Based Pet Palatability Testing

In the competitive landscape of global pet nutrition, a fundamental truth reigns supreme: the most nutritionally complete food is worthless if the animal refuses to eat it.

As professional manufacturers of food and beverage flavorings, we exist at the intersection of nutritional science and sensory delight. We understand that modern pet owners are no longer satisfied with basic sustenance for their companions. The “humanization” of pets has driven demand for premium ingredients, functional benefits, and clean labels. Yet, as formulations become more complex—incorporating specialized proteins, fibrous vegetables, and nutraceutical additives—the challenge of maintaining palatability increases exponentially.

Creating successful pet food flavors is not merely about making something taste “good” to a human palate. It is a rigorous technical discipline requiring a deep understanding of comparative physiology, volatile organic chemistry, and advanced food processing technology.

This article provides a comprehensive technical overview of how we engineer palatability for the discerning animal consumer, transforming nutritious kibble and wet food into craveable experiences.

To design effective palatants, we must first abandon human sensory biases. Dogs and cats live in sensory worlds vastly different from our own, and vastly different from each other. Palatability is a multisensory perception driven primarily by olfaction (smell), followed by gustation (taste), and influenced by texture (mouthfeel).

Canine evolutionary history as scavenging carnivores dictates their flavor preferences. While they are classified taxonomically as Carnivora, dogs are functional omnivores.

Their primary driver is scent. A dog’s olfactory epithelium is vast, containing up to 300 million scent receptors compared to a human’s relatively meager 6 million. They do not taste food in the nuanced way humans do; they “smell-taste” it. If the aroma does not signal nutritional value (primarily fat and protein), the dog may never take the first bite.

Gastronomically, dogs possess fewer taste buds than humans (roughly 1,700 vs. 9,000). They respond strongly to:

Cats present a far more complex sensory challenge for formulators. As obligate carnivores, their nutritional requirements—and therefore their sensory triggers—are strictly focused on animal tissues.

Cats are notoriously discerning, often described by pet owners as “finicky.” This is a survival mechanism. In the wild, eating the wrong thing could be fatal; therefore, cats rely on specific, rigid sensory cues before accepting food.

Key feline sensory characteristics include:

Understanding these physiological differences is foundational. A flavor system designed for a Labrador will almost certainly fail a Bengal cat.

In the pet food industry, the terms “flavor” and “palatant” are often used interchangeably, but technically, a palatant is a broader system designed to ensure consumption. A palatant system typically consists of flavor compounds (aroma), taste-active compounds (gustatory), and texturants.

The creation of high-performance savory flavors for pet food relies heavily on mimicking the chemical profile of degrading meat proteins and fats.

The cornerstone of savory flavor production is non-enzymatic browning, known as the Maillard reaction. This is the same chemical process that gives a seared steak its distinct aroma and flavor.

In a controlled industrial setting, we react reducing sugars (like xylose or glucose) with specific amino acids (like cysteine, methionine, or proline) under precise heat and pressure conditions. This cascade of chemical reactions produces hundreds of complex flavor compounds, including:

By modulating the precursors, temperature, pH, and reaction time, we can steer the flavor profile toward specific targets—creating a “roasted chicken” profile versus a “braised beef” profile.

To generate the intense umami cues required by both dogs and cats, we utilize protein hydrolysis. Using specific protease enzymes, we break down long-chain proteins from animal or plant sources into shorter peptides and free amino acids.

This process serves two functions:

Yeast extracts are invaluable natural tools for the flavor chemist. They are rich sources of natural glutamates and nucleotides (IMP and GMP). These compounds work synergistically to create a profound savory impact, effectively boosting the perception of meatiness without relying solely on animal proteins.

Fats serve as both a nutrient signal and a flavor carrier. Many aromatic flavor compounds are lipid-soluble. The quality of the fat used in the pet food coating (usually poultry fat or tallow) directly impacts how effectively aromatic compounds are released when the animal sniffs the food. Oxidized or low-quality fats will not only taste rancid but will also inhibit the performance of added top-note flavors.

Kibble Extrusion & Coating Anatomy

If pet food were simply meat and fat, our jobs would be easy. However, modern pet food is a complex matrix balancing nutrition, cost, and consumer trends.

While dogs and cats love meat, very high fresh meat inclusions in dry kibble can sometimes be counterproductive to palatability due to processing effects. When fresh meat is subjected to the high heat and shear of extrusion, its natural flavor profiles can be denatured or lost. Furthermore, high-protein diets can sometimes result in bitter peptide formation during digestion or processing. We must override these processed notes with fresh, authentic meat aromas post-extrusion.

The shift toward plant-based proteins (pea, soy, potato) introduces inherent “beany,” “green,” or bitter off-notes that are highly aversive to cats. Similarly, functional ingredients added for joint health (chondroitin sulfate), dental health (polyphosphates), or gut health (certain prebiotics) are often intensely bitter or astringent.

This requires advanced masking technology. We don’t just cover up the bad taste; we use flavor modulators that physically block bitter receptors on the animal’s tongue or use congruent flavors (like strong liver notes) that trick the brain into accepting the bitterness as part of a complex savory profile.

According to a report by the National Institutes of Health (NIH) regarding bitter taste perception, understanding the specific genetic TAS2R receptors in different species is crucial for developing effective bitter-masking agents, particularly for felines who show a wider range of bitter sensitivities than humans. (Citation 1).

Developing a great flavor is only half the battle. Delivering it effectively to the animal’s nose and tongue is equally critical. The application method depends heavily on the finished product format (dry kibble, wet loaf, chunks in gravy, semi-moist).

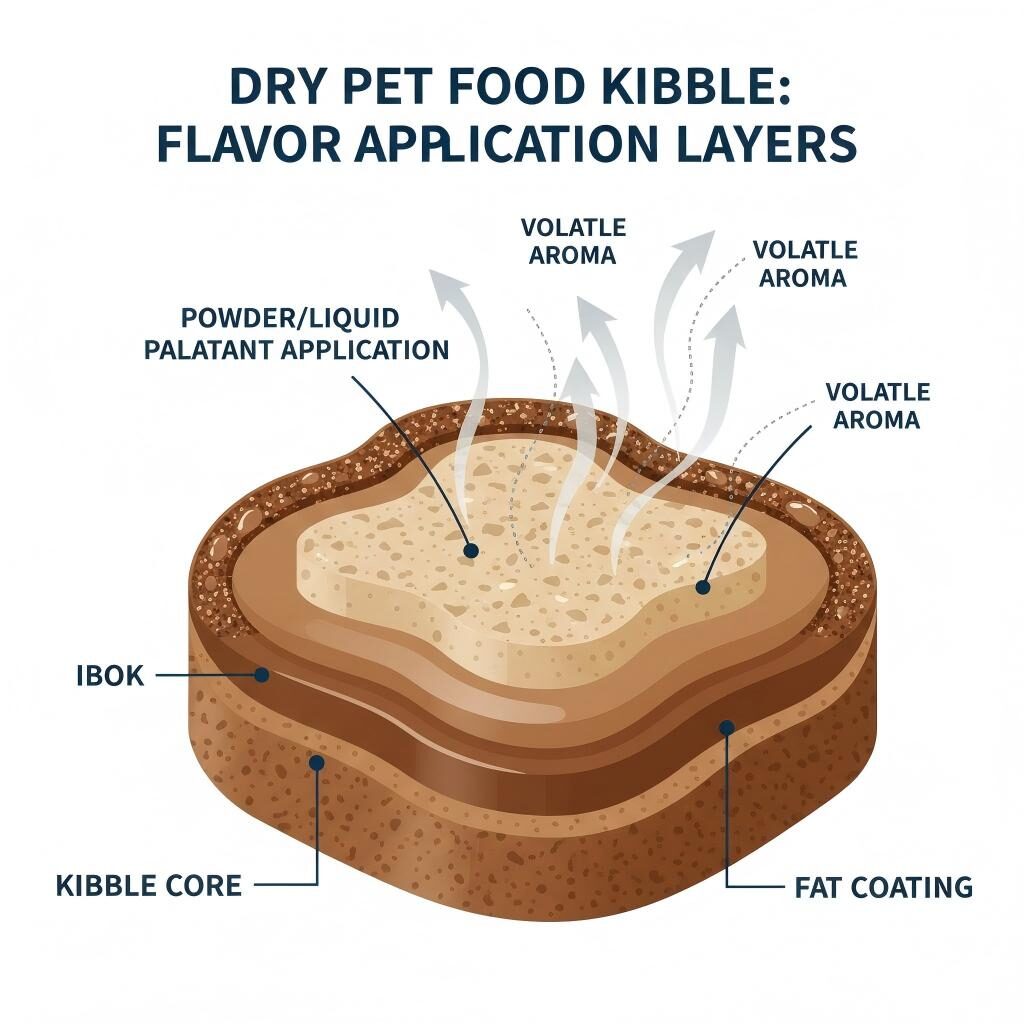

For dry pet food, flavor is almost always applied externally after the extrusion and drying process. If added internally before extrusion, the intense heat would flash-off most volatile aromas.

The standard industry practice involves a two-step enrobing process:

The sequence and temperature of application are paramount to ensure uniform coverage and prevent the fat from soaking too deeply into the kibble, which would reduce aromatic release.

In wet foods (canned or pouches), the challenge is flavor stability during the retort process (high-heat sterilization). Flavors must be engineered to withstand temperatures exceeding 120°C (248°F) for extended periods without breaking down or creating off-flavors.

Furthermore, the “gravy” or “jelly” phase is critical. It must have the right viscosity to coat the meat chunks and facilitate flavor release in the mouth. Hydrocolloids and gums used for texture can sometimes bind flavor compounds, muting their impact, a phenomenon that flavor chemists must compensate for in the dosage rate.

How do we know if a palatant works? We ask the animals.

Palatability testing is a rigorous statistical science. As manufacturers, we rely on standardized testing protocols to validate our flavor systems against benchmarks.

This is the industry standard for comparing two products. An animal is presented with two bowls simultaneously, each containing a different food (e.g., Test Diet A vs. Control Diet B). The amount consumed from each bowl is measured after a set period.

The key metric is the Intake Ratio (IR). If a dog eats 150g of Diet A and 50g of Diet B, the total consumption is 200g. The IR for Diet A is 150/200 = 0.75. An IR significantly greater than 0.5 indicates a preference.

However, care must be taken to account for side bias (animals always choosing the left or right bowl) by rotating bowl positions over multiple days of testing.

In this test, the animal is offered only one food item. We measure total consumption, speed of eating, and behavioral cues (tail wagging, enthusiasm, licking the bowl clean). This tests pure acceptance rather than competitive preference. It is useful for evaluating if a new formulation is “good enough” to be introduced to the market without causing refusal.

Industry associations like the Pet Food Institute often emphasize that while nutritional adequacy is verified by lab analysis, palatability can only be verified by live animal feeding trials under controlled conditions. (Citation 2).

Controlled Beagle Feeding Study

The pet food flavor industry does not operate in a vacuum. We are heavily regulated and heavily influenced by human consumer trends.

In the United States, the Association of American Feed Control Officials (AAFCO) sets the definitive standards for ingredient definitions.

For a flavor to be labeled as “Natural Flavor” on a pet food bag, it must meet the AAFCO definition, which generally requires the flavor to be derived solely from animal or plant sources (meat, poultry, fish, vegetables, yeast, eggs, dairy) via physical processing, heat treatment, or enzymatic hydrolysis.

Synthetic flavor chemicals, even if they are chemically identical to those found in nature, cannot be used in a product labeled “natural.” As the market shifts overwhelmingly toward natural claims, our R&D focuses intensely on optimizing natural extraction and reaction technologies.

Pet owners increasingly view their pets as family members and project their own food values onto them. This drives demand for:

According to recent market analysis by Pet Food Processing magazine, the demand for premium, human-grade attributes in pet food continues to influence palatant development, pushing suppliers to innovate with cleaner label ingredients that still deliver robust flavor profiles. (Citation 3).

Developing a winning pet food is a collaborative effort. A flavor supplier should not just be a vendor of drums of liquid or bags of powder; they must be an extension of your R&D team.

Generic, off-the-shelf palatants rarely succeed in modern, complex formulations. The base kibble composition—its protein source, fat content, moisture level, and processing history—dramatically affects how a flavor performs. A palatant that works brilliantly on a chicken-and-rice diet may fall flat on a grain-free salmon diet.

An effective flavor partner provides:

As highlighted by research in the journal Animals, the interaction between food texture, aroma release, and the animal’s individual sensory biology is so complex that a “one-size-fits-all” approach to palatability is functionally impossible in the premium sector. (Citation 4).

At the end of the day, pet owners want two things: they want their pets to be healthy, and they want to see the joy their pets experience when eating.

If a pet refuses to eat a therapeutic diet designed for kidney health because it is bitter, the diet fails. If a dog enthusiastically devours a bowl of kibble, the owner feels a strong emotional connection and gratification, reinforcing brand loyalty.

Our role as flavor scientists is to bridge that gap. By applying rigorous chemistry, understanding animal physiology, and utilizing advanced processing technologies, we turn nutritional necessities into moments of delight for cats and dogs. We ensure that the best nutrition is also the most delicious choice.

Emotional Pet Bond & Mealtime Success

Are you facing challenges with a new high-protein formulation or struggling with acceptance notes in a functional diet? Our team of flavor chemists and sensory experts is ready to collaborate.

Contact us today to schedule a technical consultation or request customized flavor samples tailored to your specific base formulation. Let’s create the next generation of craveable pet nutrition together.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Citations:

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.