Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 14, 2025

Sustainable Flavor Ecosystem

In the rapidly evolving global food and beverage industry, sustainability is no longer a buzzword — it is a strategic priority. Consumers are increasingly concerned not only about taste and quality but also about the environmental and ethical impact of what they consume. For manufacturers, this means that flavor sourcing — from agricultural inputs to production and logistics — must align with the principles of eco-responsibility and traceability.

According to a 2024 report by the United Nations Environment Programme (UNEP), sustainable sourcing practices across the food industry could reduce global greenhouse gas emissions by up to 30% by 2030 if widely implemented (UNEP, 2024)¹. This shift presents both a challenge and a profound opportunity for food flavor producers.

At CUIGUAI Flavoring, we have embraced sustainability as a foundation of product design, raw material selection, and flavor innovation. In this article, we explore how sustainable flavor sourcing is transforming modern food manufacturing — from farm to formulation — and outline key practices for building a resilient, eco-friendly flavor supply chain.

Sustainable flavor sourcing refers to the ethical and environmentally responsible procurement of raw materials used to produce food and beverage flavors. It involves balancing three interconnected pillars:

A single flavor molecule — such as vanillin, limonene, or menthol — can have a complex sourcing story. Traditional flavor supply chains often rely on intensive agricultural extraction or petrochemical synthesis. Sustainable sourcing redefines this model by promoting renewable, natural, or biotechnologically derived alternatives.

For example:

These examples illustrate how circular economy principles can be embedded into the flavor industry, aligning sensory excellence with environmental care.

Many traditional flavor crops — such as vanilla, cocoa, and coffee — are resource-intensive and often linked to deforestation, soil degradation, and biodiversity loss. In Madagascar, for example, 80% of vanilla cultivation occurs in ecologically sensitive regions where forest clearance threatens local habitats (World Bank, 2023)².

Moreover, conventional flavor farming may rely heavily on chemical fertilizers and pesticides, contributing to soil depletion and water contamination.

While synthetic flavor compounds have provided consistency and scalability, they often depend on non-renewable petroleum derivatives. This approach increases greenhouse gas emissions and ties the flavor industry to the volatile energy sector.

As sustainability becomes a defining business factor, food manufacturers are seeking low-carbon synthetic alternatives, such as bio-based flavor precursors derived from sugarcane, algae, or plant waste biomass.

Traditional extraction and distillation processes are often energy-intensive. Many manufacturers are transitioning to supercritical CO₂ extraction and green solvent technologies that significantly reduce energy use and chemical waste.

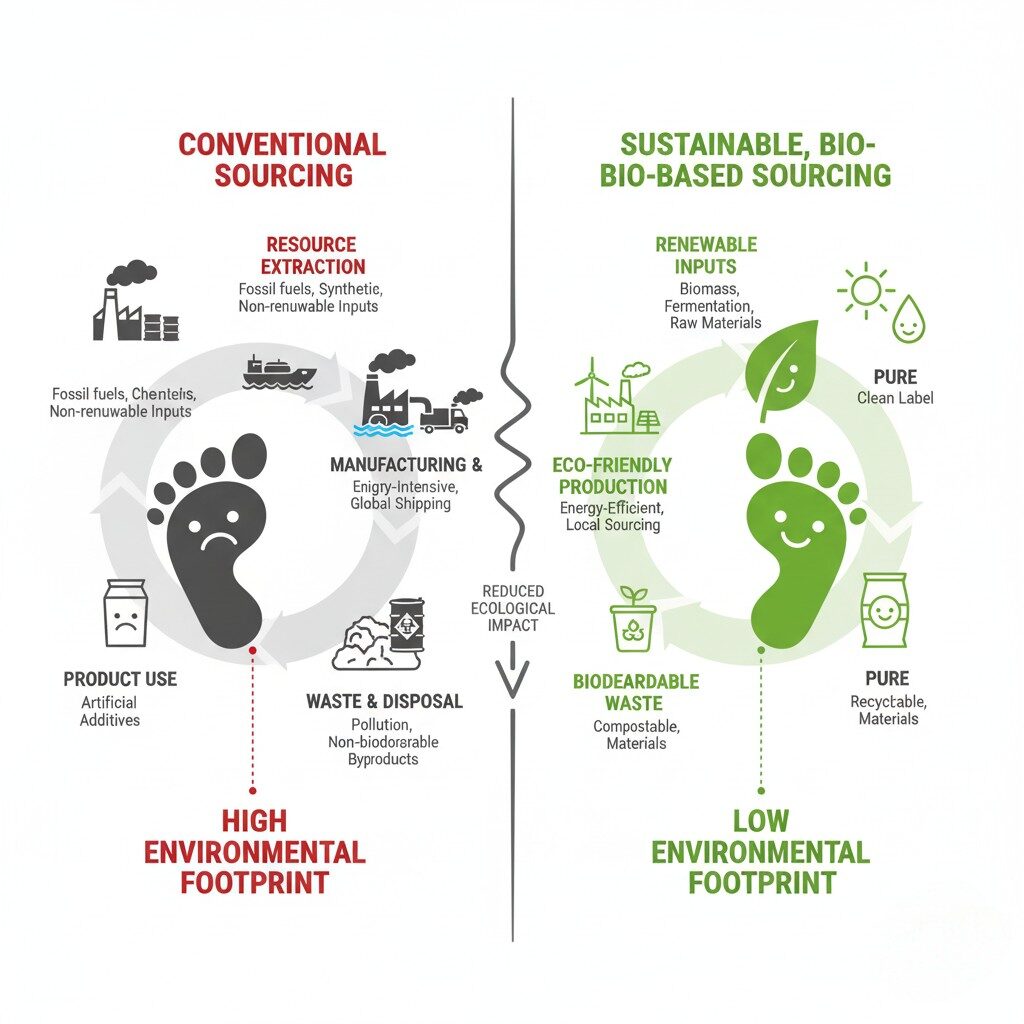

Flavor Sourcing Environmental Footprint

Transitioning toward sustainable flavor sourcing requires a multi-tiered strategy encompassing raw material selection, supplier collaboration, energy management, and transparent reporting.

Modern flavor manufacturers are increasingly applying traceability systems to ensure that every ingredient — from vanilla beans to essential oils — can be traced to verified sustainable sources.

These measures not only strengthen corporate responsibility but also meet growing regulatory and consumer expectations.

Advances in biotechnology now allow flavor molecules to be produced through fermentation, enzymatic synthesis, or microbial bioconversion — processes that use renewable feedstocks and significantly reduce waste.

Examples include:

Such innovations enable manufacturers to reduce dependence on volatile agricultural yields while maintaining consistent sensory profiles.

Sustainability in flavor manufacturing extends beyond raw materials. Leading producers are investing in solar, wind, and biomass energy systems to power production facilities. According to the U.S. Department of Energy, industrial operations that switch to renewable energy can cut operational emissions by up to 40% (U.S. DOE, 2023)³.

By integrating renewable power, efficient heat recovery, and closed-loop water systems, manufacturers can achieve a net-positive environmental footprint while improving long-term cost efficiency.

Sustainable Flavor Facility Schematic

While sourcing is crucial, packaging and logistics represent the final stages of a sustainable flavor lifecycle. Many manufacturers are now adopting eco-conscious packaging solutions such as:

Optimizing distribution networks also reduces environmental impact — for instance, using route optimization algorithms and electric delivery fleets can cut fuel consumption by over 25%, according to research published in Food Manufacturing Journal (2024)⁴.

Sustainability is not solely environmental — it also encompasses social equity. A truly sustainable flavor supply chain supports the livelihoods of smallholder farmers who grow botanical crops. By offering training programs, fair pricing, and agricultural education, companies can empower these communities and ensure long-term ingredient stability.

Eco-conscious sourcing helps manufacturers mitigate risks associated with climate change, resource scarcity, and geopolitical instability. For instance, diversified sourcing from certified suppliers reduces exposure to regional crop failures or political disruptions.

While sustainable sourcing may initially increase operational costs, it creates long-term economic value by strengthening brand trust, meeting regulatory standards, and opening new markets for clean-label and organic products. As consumers increasingly favor transparent brands, sustainability becomes a driver of revenue growth rather than a cost center.

The digital revolution has brought powerful tools for monitoring sustainability across the flavor lifecycle.

Blockchain technology enables immutable, transparent records for every stage of production — from raw material procurement to finished product delivery. With QR-code-based traceability, consumers and business clients can verify sustainability claims instantly.

Artificial intelligence and IoT sensors are being used to monitor energy usage, temperature control, and raw material efficiency in real time. These technologies empower manufacturers to identify inefficiencies and reduce carbon output dynamically, enhancing sustainability metrics across the value chain.

The global flavor industry is being reshaped by consumer demand for transparency and eco-consciousness. Studies show that over 70% of global consumers prefer brands that demonstrate environmental responsibility (NielsenIQ, 2024).

Clean-label trends are influencing flavor manufacturers to replace artificial additives with natural, traceable ingredients. This shift requires suppliers to ensure authenticity, consistency, and sustainability in every flavor compound.

Labels such as “natural,” “organic,” and “sustainably sourced” now carry significant marketing power — but they must be backed by verifiable certification to maintain consumer trust. Therefore, transparency and compliance with standards like ISO 26000 (Social Responsibility) and ISO 14001 (Environmental Management) are essential.

At CUIGUAI Flavoring, sustainability is integrated into every phase of our product development and manufacturing process:

Through continuous improvement and third-party sustainability audits, CUIGUAI Flavoring aims to set a benchmark for eco-conscious innovation in the global flavor industry.

The future of flavor manufacturing will be data-driven, renewable, and traceable. Sustainability will increasingly be quantified through lifecycle analysis (LCA), carbon accounting, and third-party certification.

By 2035, it is expected that over 60% of global flavor production will rely on renewable or bio-engineered feedstocks, reducing the industry’s dependency on fossil-based chemicals (FAO Report, 2024)¹.

Sustainability is not a passing trend; it is the core foundation of future flavor excellence.

Green Flavor Lab

Sustainable flavor sourcing represents more than environmental compliance — it embodies a holistic vision of quality, ethics, and innovation. As food manufacturers face growing expectations from consumers and regulators alike, the ability to create eco-conscious, traceable, and high-performance flavors will determine market leadership.

At CUIGUAI Flavoring, we invite partners across the food and beverage industry to join us in redefining flavor creation — one sustainable molecule at a time.

If you are a food or beverage manufacturer, R&D specialist, or flavor product developer seeking to enhance your formulations with sustainably sourced, high-quality food-grade flavors, contact our technical team for a free consultation or sample request.

👉 Contact us today to explore how CUIGUAI Flavoring can help you design eco-friendly flavors that delight consumers and support a sustainable future.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at【www.cuiguai.cn】

Food Manufacturing Journal, 2024. “Optimizing Green Logistics in Food Ingredient Supply Chains.”

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.