Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 10, 2025

Modern Flavor Sourcing Dashboard in Food R&D Lab – Real-time Analytics & Supplier Comparison

The global food and beverage industry is evolving faster than ever. Consumer demand for innovation, transparency, and sustainability has driven profound changes not just in what we eat, but in how ingredients are sourced and developed.

For food manufacturers, one of the most significant shifts lies in flavor sourcing—a process that historically relied on manual supplier management, slow communication, and opaque quality verification. Today, digital transformation is redefining that landscape.

Through cloud-based procurement platforms, data analytics, and AI-driven traceability, manufacturers are now able to streamline flavor sourcing, minimize risk, and accelerate time to market.

According to a 2023 Deloitte Digital Supply Chain report, companies that have adopted digital procurement technologies experience 30–50% faster supplier onboarding and 20% lower operational costs across sourcing categories. For the flavor industry, where time-sensitive innovation and ingredient quality are paramount, this represents a major competitive advantage.

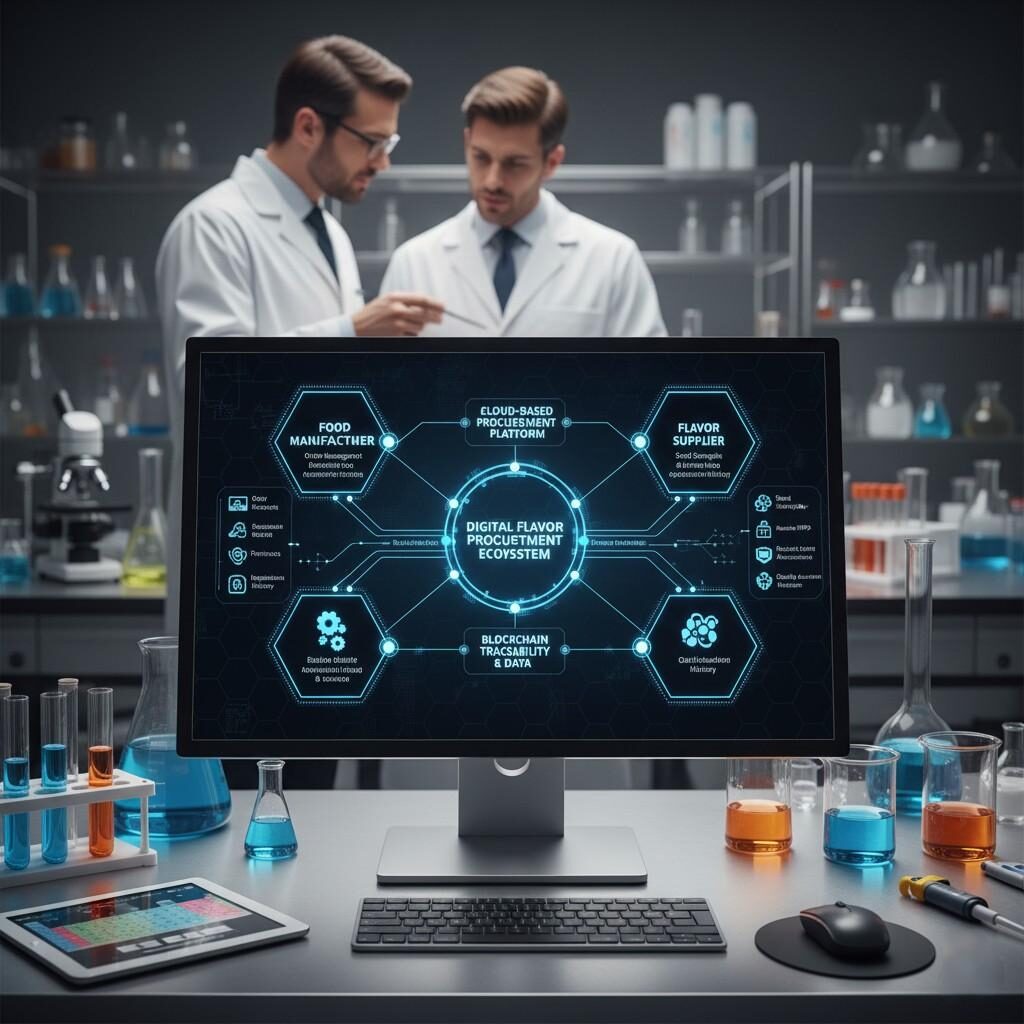

Digital transformation in the flavor supply chain doesn’t simply mean automating paperwork. It involves integrating intelligent technologies—such as cloud computing, AI, IoT (Internet of Things), and blockchain—into every stage of the flavor procurement process.

This transformation affects:

By digitizing these touchpoints, food manufacturers gain unprecedented visibility and control over their flavor ingredient lifecycle—from raw extract origin to final delivery.

Historically, flavor sourcing has faced several pain points:

Digital transformation directly addresses these inefficiencies, converting procurement from a reactive function into a strategic, data-driven advantage.

Traditional vs. Digital Flavor Sourcing Comparison Chart – Speed, Cost & Quality

Modern flavor manufacturers are now adopting cloud-based procurement systems that connect all stakeholders—R&D, quality control, purchasing, and suppliers—on one unified platform.

These systems allow:

According to Gartner (2024), over 70% of top global food manufacturers have integrated at least one cloud-based sourcing tool, significantly improving operational agility and compliance readiness.

AI plays a transformative role in analyzing procurement data and predicting optimal sourcing decisions.

By leveraging machine learning algorithms, AI can:

This predictive intelligence enables manufacturers to make data-backed purchasing decisions, ensuring that both quality and price are balanced.

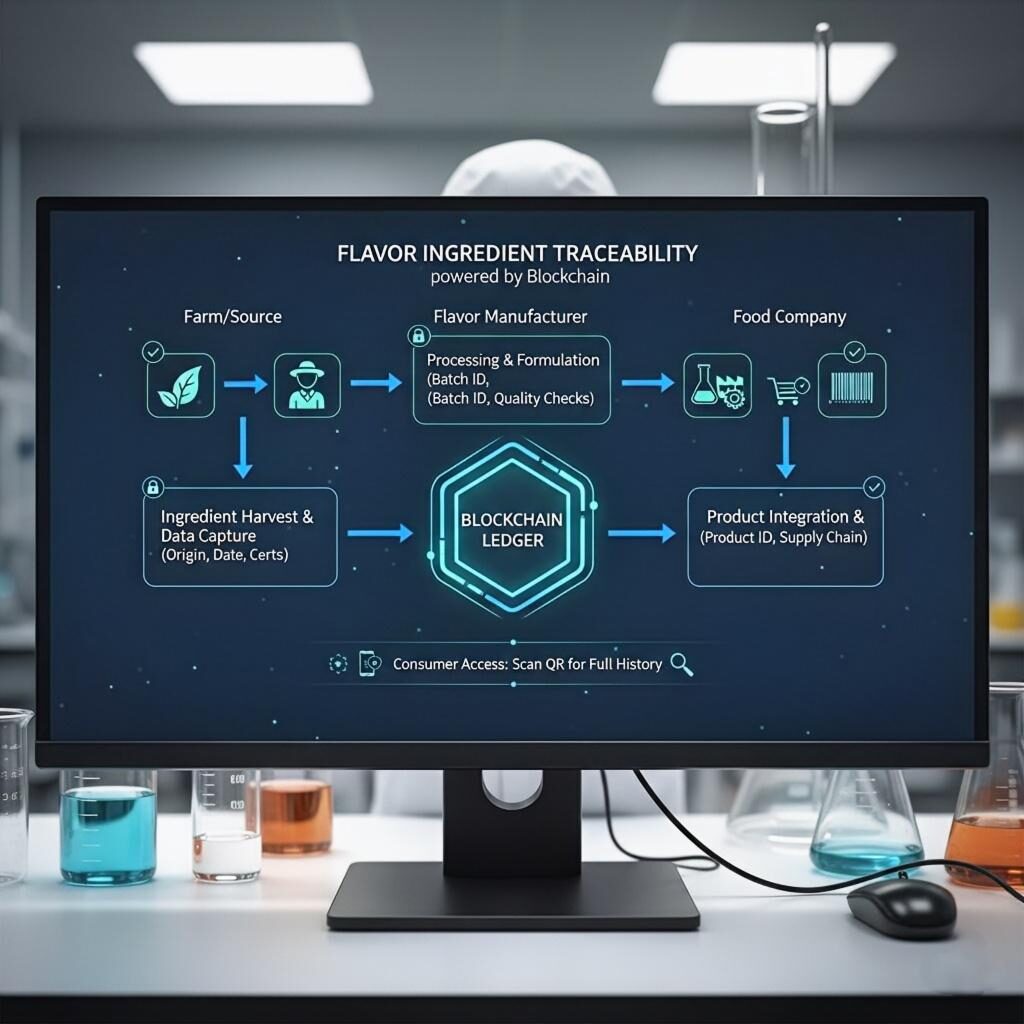

Blockchain technology is becoming a cornerstone of digital sourcing in the flavor industry. With its immutable ledger system, blockchain ensures that every transaction—from raw material harvesting to final product delivery—is recorded and verifiable.

In flavor sourcing, blockchain helps to:

The World Economic Forum (2023) highlights blockchain as a critical tool for increasing transparency and consumer trust in food ingredients, particularly in natural and organic categories. (source: WEF Food Supply Chain Report).

Blockchain Flavor Ingredient Traceability Flow Diagram – Farm to Fork

IoT devices—such as smart sensors and connected scales—enable real-time tracking of temperature, humidity, and shipment conditions during flavor transport.

This ensures that flavor compounds, especially natural and volatile ones, are stored and delivered within ideal conditions to prevent degradation.

IoT integration allows procurement teams to:

According to the U.S. Food and Drug Administration (FDA), adopting digital traceability tools such as IoT systems supports safer and faster food supply chains, aligning with the FDA’s New Era of Smarter Food Safety initiative (source: FDA.gov, 2023).

With digital systems, procurement teams can automate repetitive tasks such as quote collection, compliance documentation, and order tracking.

Digital sourcing platforms reduce:

The result? Faster product development cycles, allowing manufacturers to respond quickly to seasonal flavor trends or regional taste innovations.

Digital transformation brings traceability to the forefront. By centralizing supplier quality data and using digital quality certificates, companies can:

For flavor-intensive products—such as beverages, confectionery, and snacks—consistency is key. Digital systems ensure that every flavor batch meets sensory and chemical benchmarks, verified through data, not assumption.

Digital sourcing provides visibility into global supplier markets, empowering buyers to diversify sources without compromising quality.

AI-driven price analytics help identify:

Manufacturers can then make strategic procurement decisions that balance cost efficiency with supply stability—especially crucial for natural extracts prone to regional price volatility (e.g., citrus oils, vanilla, mint).

Sustainability has become a top purchasing criterion. Digital tools allow companies to verify environmental and social performance data directly from suppliers.

Platforms now integrate ESG scoring systems, which rate suppliers on:

According to Harvard Business Review (2023), manufacturers that integrate digital sustainability verification into procurement reduce supply-chain-related emissions by up to 35%, while improving brand reputation and consumer trust.

Transitioning from traditional to digital flavor sourcing requires careful planning. Below is a strategic roadmap adopted by leading food manufacturers:

Conduct an internal audit of your current sourcing process. Identify areas that are most manual, time-consuming, or error-prone—such as vendor communication or document verification.

Choose a cloud-based procurement solution that supports:

Look for platforms that are customizable for flavor and fragrance sourcing, as ingredient traceability requirements are more stringent than in general commodities.

Create uniform digital templates for supplier data, flavor specification sheets, and compliance documentation. Standardization ensures that information from different suppliers can be compared automatically.

Ensure that procurement and quality control teams understand how to interpret and act on digital insights.

Investing in digital literacy training empowers staff to leverage analytics tools effectively.

Collaborate with professional flavor manufacturers who already operate within a digitally integrated ecosystem—including automated COA generation, digital sensory databases, and supply traceability tools.

Manufacturers such as CUIGUAI Flavoring provide end-to-end digital support, from GC–MS aroma profiling data to digital sample requests and quality traceability, enabling faster and more efficient procurement collaboration.

Digital Flavor Procurement Ecosystem

Many food manufacturers have already seen measurable gains from digitizing flavor sourcing.

For instance:

The combination of real-time visibility, predictive analytics, and digital traceability transforms procurement from a cost center into a strategic growth engine.

As technology continues to advance, the future of flavor sourcing will center on smart automation, sustainability integration, and consumer-facing transparency.

Emerging trends include:

These innovations will redefine how manufacturers collaborate with flavor houses—moving from transactional relationships to strategic, data-driven partnerships that accelerate innovation and reduce waste.

Digital transformation in flavor sourcing is not just about adopting new software—it’s about building an intelligent, transparent, and sustainable sourcing ecosystem.

By leveraging technologies such as AI, blockchain, IoT, and cloud-based platforms, food and beverage manufacturers can:

Ultimately, digital sourcing transforms procurement into an innovation engine—fueling better flavors, faster launches, and stronger brands.

At CUIGUAI Flavoring, we empower food and beverage manufacturers to streamline their sourcing through digital innovation, data transparency, and technical expertise.

🔍 Request a free digital consultation with our R&D and procurement specialists

📦 Get a free sample kit of our top-performing food-grade flavor concentrates

🤝 Discover how digital integration with CUIGUAI Flavoring can optimize your entire flavor supply chain

📧 Contact us today to begin your digital flavor transformation journey.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at【www.cuiguai.cn】

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.