Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 13, 2025

Natural Flavor GC-MS Analysis

In today’s globalized food and beverage industry, the demand for natural and clean-label flavorings has surged dramatically. Consumers are increasingly seeking transparency, sustainability, and purity in the ingredients behind their favorite foods and drinks. For flavor manufacturers, this evolution brings both opportunity and responsibility—especially in managing the safety of agricultural raw materials used in natural flavor creation.

Among the most critical aspects of safety assurance is the control of pesticide residues. While pesticides play a vital role in modern agriculture, ensuring crop yields and protection from pests, their residual presence in flavor raw materials poses a direct challenge to food safety, regulatory compliance, and consumer trust.

This blog post explores in depth how flavor manufacturers can uphold purity and safety standards by effectively detecting, managing, and preventing pesticide residues throughout the production chain—from farm to finished flavor concentrate.

We’ll examine the global regulatory frameworks, the analytical testing technologies, and the best operational practices that safeguard the integrity of food-grade flavors in international trade.

Pesticides encompass a diverse class of chemicals—including insecticides, herbicides, fungicides, and rodenticides—used to protect crops and improve yields. While essential for sustainable farming, their residues can persist on or within agricultural produce.

Natural flavor ingredients are derived from a wide variety of plants such as:

These crops are often exposed to environmental contaminants, including pesticide drift from neighboring farms, soil accumulation, or post-harvest treatments. As a result, trace residues can enter essential oils, extracts, or distillates during flavor production.

Even when residues are present in trace amounts, exceeding regulatory limits can result in:

Therefore, the presence of pesticide residues is not just a quality control issue—it’s a strategic compliance and brand protection concern for every flavor producer.

Different markets enforce varying limits on pesticide residues, making global compliance a complex but essential challenge. Below is a summary of the major frameworks guiding safety standards.

The Codex Alimentarius Commission (CAC)—jointly established by the FAO and WHO—sets international Maximum Residue Limits (MRLs) for hundreds of pesticides across numerous food categories. These serve as benchmark standards used by both developing and developed nations to harmonize regulations and facilitate fair trade.

(Source: FAO/WHO Codex Alimentarius Commission – https://www.fao.org/fao-who-codexalimentarius)

Codex MRLs are scientifically determined based on toxicological assessments and acceptable daily intake (ADI) values, ensuring consumer safety without impeding agricultural productivity.

The EU enforces one of the strictest regulatory systems for pesticide residues. Governed by Regulation (EC) No 396/2005, the European Food Safety Authority (EFSA) establishes specific MRLs for a broad range of agricultural products.

(Source: European Commission, Food Safety Portal – https://food.ec.europa.eu)

The EU also applies the precautionary principle—meaning if a pesticide is not explicitly authorized, its MRL is effectively set at zero. This makes pesticide management especially crucial for exporters supplying flavor ingredients into the European market.

In the U.S., pesticide regulation is divided between the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA).

Flavor manufacturers importing botanical extracts must ensure that raw materials meet the EPA-established tolerance limits to prevent customs rejections or penalties.

Asia represents one of the fastest-growing regions for flavor production and export. Countries like China, Japan, and South Korea maintain MRL standards based on Codex but tailored to local crops and consumption patterns.

(Source: China CFSA – http://www.cfsa.net.cn)

For example:

Navigating these multi-layered regulatory environments demands global awareness and rigorous internal documentation within every flavor production facility.

Ensuring residue-free flavors requires the use of advanced analytical instrumentation capable of detecting and quantifying minute pesticide traces.

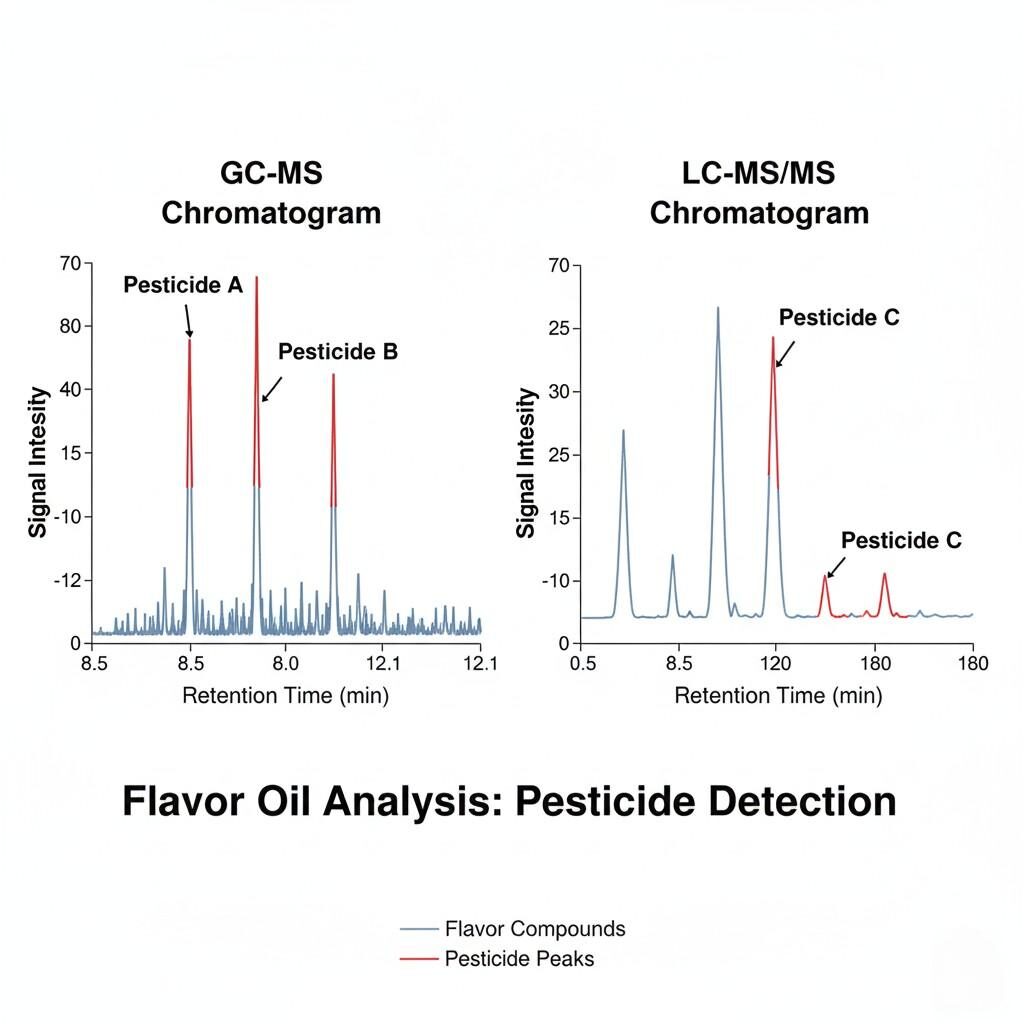

GC–MS/MS remains the industry standard for volatile and semi-volatile pesticide detection in essential oils and other non-polar matrices. It combines high-resolution separation with molecular-level identification.

Typical analytes: organochlorines, organophosphates, pyrethroids.

LC–MS/MS is essential for detecting polar, thermally unstable, or non-volatile pesticides—common in herbal and fruit extracts. This method allows simultaneous screening for hundreds of compounds at ppb (parts per billion) sensitivity.

Developed in the early 2000s, QuEChERS (“Quick, Easy, Cheap, Effective, Rugged, and Safe”) revolutionized pesticide residue testing. It simplifies extraction and cleanup, improving throughput while maintaining accuracy across diverse sample types.

Reliable testing requires method validation under ISO/IEC 17025 standards. Laboratories must demonstrate accuracy, precision, recovery, linearity, and limit of detection (LOD). These certifications assure customers and regulators that analytical results are trustworthy and reproducible.

Pesticide Detection Chromatograms

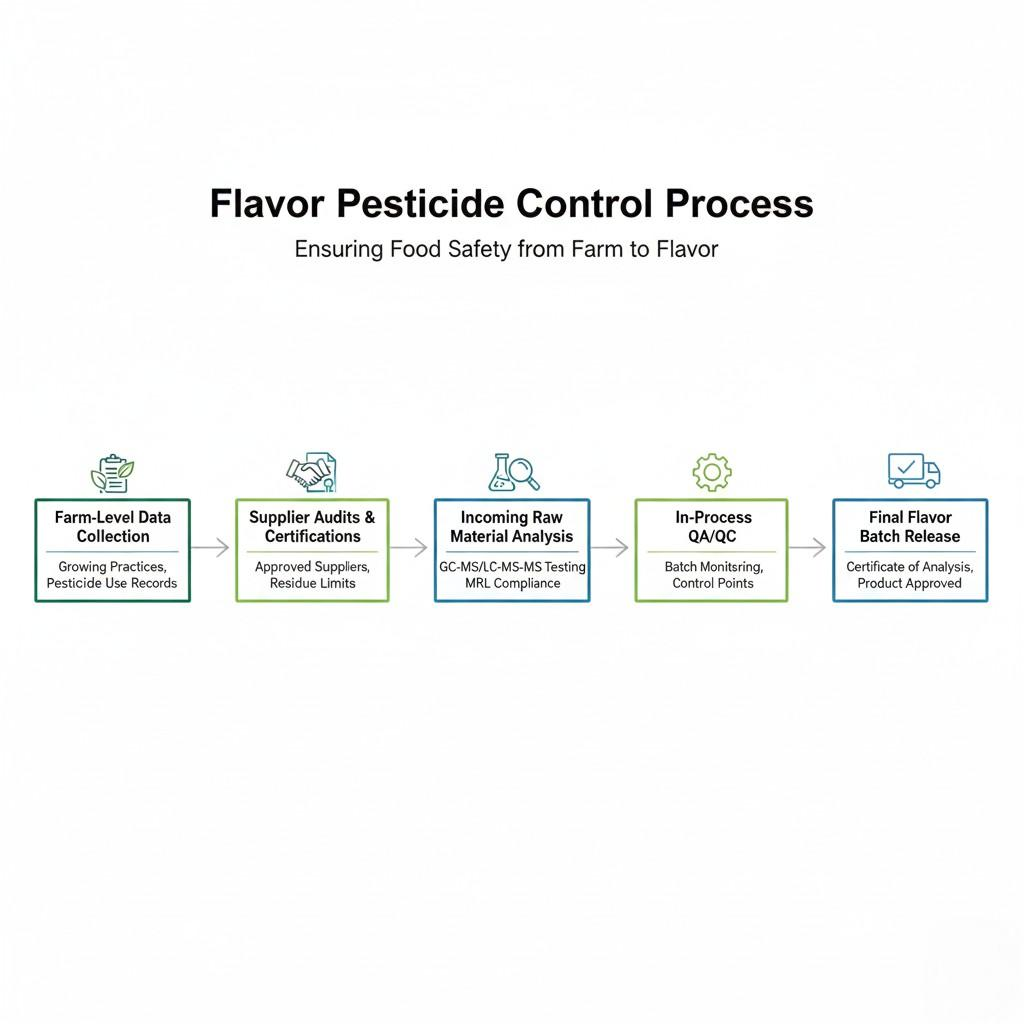

Analytical testing, while essential, is reactive. Preventive control begins upstream—through supplier qualification and traceability systems.

Flavor manufacturers should audit suppliers for:

Approved suppliers should be regularly reassessed to ensure ongoing compliance and performance.

Digital traceability tools (such as ERP-integrated systems or blockchain) now allow flavor manufacturers to track every lot—from farm to extraction to finished flavor.

Each batch can be traced back to:

This system not only supports compliance but also strengthens consumer confidence in transparent sourcing.

Many premium flavor producers are moving toward direct farming partnerships, ensuring control over cultivation practices and reducing reliance on volatile supply chains. This helps maintain consistent residue profiles and guarantees cleaner raw materials.

Risk assessment frameworks help manufacturers prioritize testing resources. Factors influencing risk include:

By focusing on high-risk ingredients, companies can allocate analytical resources efficiently without compromising safety.

Under HACCP (Hazard Analysis and Critical Control Point), pesticide residue management can be incorporated as part of the hazard analysis phase. Critical control points might include:

This systematic approach integrates chemical safety into the overall food safety management plan.

Each raw material batch should be accompanied by:

This documentation not only satisfies audits but also builds a robust evidence chain during export inspections.

Pesticide Control Flow

The consequences of exceeding pesticide limits go far beyond a failed test. They can lead to substantial financial losses, legal liabilities, and brand erosion.

According to the European RASFF (Rapid Alert System for Food and Feed), hundreds of food and ingredient consignments are flagged annually due to pesticide violations—many of which include flavoring materials or herbal extracts. Each incident underscores the cost of inadequate preventive control.

| Category | Best Practice | Outcome |

| Sourcing | Procure from certified suppliers following GAP/GACP standards | Reduced contamination risk |

| Testing | Use both GC–MS/MS and LC–MS/MS for comprehensive coverage | Accurate detection |

| Documentation | Maintain traceability for all batches | Regulatory transparency |

| Training | Educate procurement and QC teams on pesticide trends | Proactive management |

| Auditing | Perform annual and surprise audits | Supplier accountability |

| Improvement | Continuously evaluate residue data trends | Continuous compliance |

These measures collectively strengthen a company’s food safety culture, aligning technical excellence with consumer expectations.

Artificial intelligence can predict pesticide risk patterns by analyzing:

This allows companies to proactively adjust sourcing before problems occur.

Blockchain offers immutable, tamper-proof traceability records. By linking farm data, analytical results, and logistics, it provides real-time visibility across supply chains—crucial for export documentation.

Recent innovations in biosensors and portable spectrometers enable near-field pesticide testing without laboratory infrastructure. This enhances agility in raw material acceptance and batch verification.

Certified Safe Natural Flavor

The long-term vision for the flavor industry is zero-residue certification—achieved through sustainable agriculture, controlled sourcing, and advanced screening technologies. As more brands shift toward organic and clean-label claims, this commitment will differentiate leaders from laggards.

Regulatory bodies are also evolving. Future frameworks may demand comprehensive environmental traceability, linking pesticide control not just to product safety but also to biodiversity and soil health metrics.

For flavor producers, investing in science-based compliance systems today will define their competitiveness in tomorrow’s global markets.

Managing pesticide residues is far more than a regulatory checkbox—it’s an ethical and strategic commitment to quality. Clean, safe, and transparent flavoring ingredients form the foundation of trust between manufacturers, brands, and consumers.

At CUIGUAI Flavoring , we uphold a rigorous pesticide control program that combines:

Our mission is to deliver safe, compliant, and innovative flavor solutions that meet the highest global standards of food safety.

For technical consultations, partnership discussions, or free flavor sample requests, contact our expert R&D team today.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.cn]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.