Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Dec 18, 2025

Premium Free From Foods

The “Free From” movement has transcended its origins as a niche category catering solely to medical necessity. Today, it is a dominant, high-growth segment driven by a confluence of rising allergy prevalence, proactive health consciousness, and lifestyle choices (veganism, paleo, flexitarianism) [4.2]. The global Free From Food Market, valued at over $114 billion in 2025, is projected to reach over $212 billion by 2030, reflecting a robust CAGR of approximately 13.25% [4.1].

This explosive growth creates an urgent mandate for food and beverage manufacturers: to deliver products that are safe, compliant, and, critically, indistinguishable in taste and mouthfeel from their conventional counterparts.

The challenge for the flavor industry is immense. Removing major allergens—such as milk, wheat, eggs, nuts, and soy—often strips the food matrix of its most fundamental sensory contributors: fat, emulsification, protein structure, and the Maillard reaction precursors.

This comprehensive technical guide details the molecular flavor strategies and rigorous supply chain protocols required to navigate the complexities of the allergen-conscious market, ensuring deliciousness remains non-negotiable.

Working within the “Free From” category requires an absolute commitment to regulatory compliance and an obsessive focus on preventing cross-contact. For flavor manufacturers, this diligence begins at the raw material source.

The definition of a “major food allergen” varies significantly between jurisdictions, creating a complex web of compliance for global brands [3.2].

The most critical technical challenge for flavor manufacturers is eliminating the risk of allergen cross-contact within their own production facilities.

The risk assessment involves tracking hundreds of raw materials against the global allergen lists and implementing a robust Allergen Matrix and Changeover Grid to prevent contamination during flavor batch production [1.1].

Removing a major allergen necessitates compensating for three critical sensory deficits: Aesthetic Deficit (e.g., color, aroma), Structural Deficit (e.g., mouthfeel, texture), and Flavor Deficit (the characteristic taste profile).

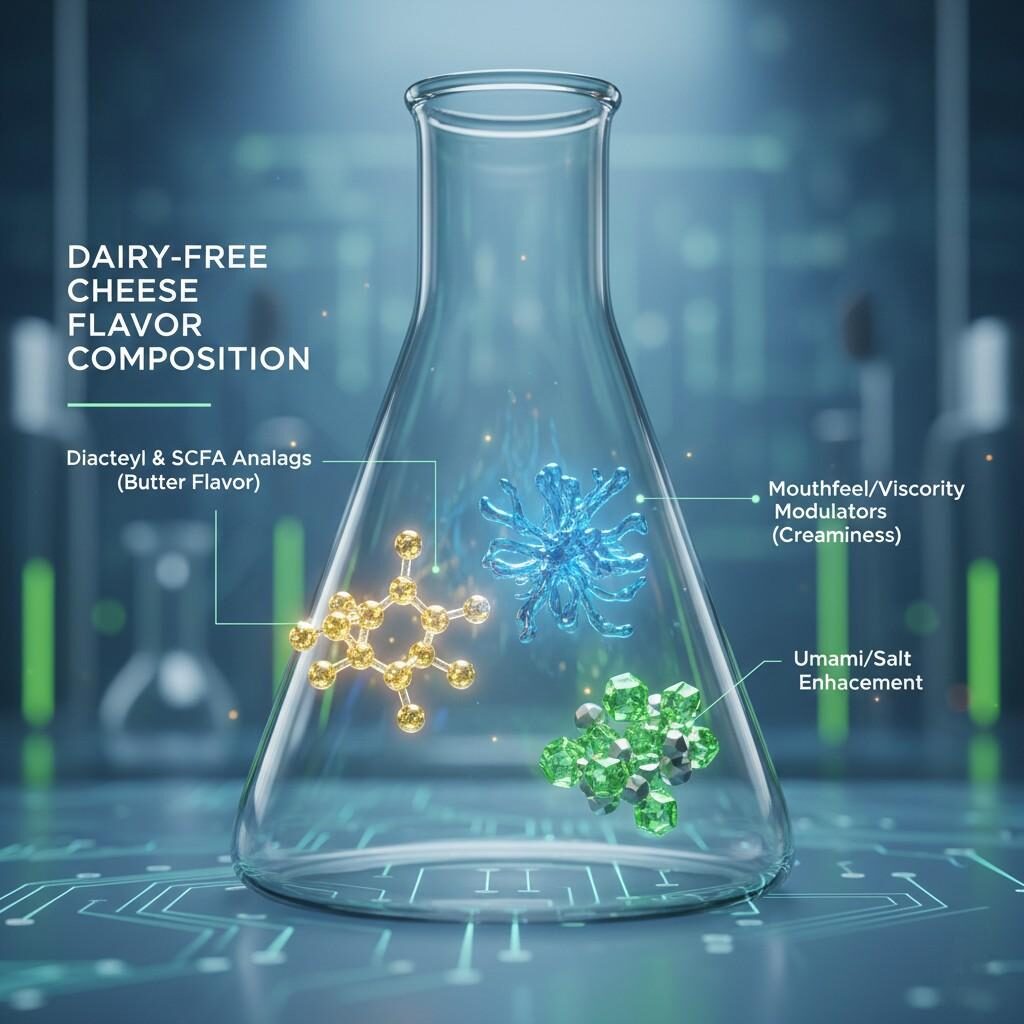

Dairy is arguably the most challenging allergen to replace, as milk solids and fats provide not only flavor but also a unique richness, body, and emulsification structure [2.5].

Gluten-free matrices (based on rice, corn, or potato starch) are notorious for their bland flavor, dry texture, and rapid staling rate.

The fastest-growing subset of the “Free From” market is plant-based alternatives (meat, dairy substitutes), which rely heavily on pea, soy, or rice proteins. These proteins contain inherent off-notes (beany, earthy, bitter, astringent) that are a significant barrier to consumer acceptance [2.4].

| Off-Note Source | Chemical Cause | Technical Flavor Solution |

| Pea/Soy Protein | Hexanal, Nonenal, Saponins | Bitter Receptor Blockers: Natural molecules (often yeast-based or botanical extracts) that physically and chemically interfere with the T2R bitter taste receptors [2.1, 2.4]. |

| Minerals/Vitamins | Metal Ions (Fe²⁺,Zn²⁺) | Metallic Maskers: Citrate salts and specific amino acids that chelate (bind) to the metal ions, preventing them from binding to taste receptors. |

| Alternative Sweeteners | Sucralose, Stevia glycosides | Linger/Aftertaste Modulators: Yeast extracts (umami-rich) or specific flavor compositions that neutralize the often-metallic or licorice-like lingering aftertaste [2.4]. |

High-Precision Masking [2.1] is an engineered approach using AI-enabled design to develop customized modulation solutions that neutralize unwanted notes without dulling the desired flavor character [2.1].

Engineered Dairy-Free Flavor

Success in the “Free From” space is not just about avoiding allergens; it’s about leading the market with superior, trend-forward flavor experiences.

Consumers associate “Free From” with overall health and purity, driving a demand for natural and clean-label flavor solutions [4.2].

The convergence of the “Free From” and Functional Food movements is a key growth area [1.3].

The Free From segment is a perfect canvas for global flavor exploration. A consumer restricted by traditional allergen-containing foods is eager for culinary adventure elsewhere.

Allergen Safety Lab to Plant

The technical complexities of the “Free From” market demand a true partnership between the brand and the flavor manufacturer. This partnership goes beyond simple ordering; it involves co-engineering the sensory experience from the ground up.

We begin every “Free From” project with a comprehensive Sensory Deconstruction of the conventional, full-allergen product. Our flavorists map the desired flavor’s temporal profile—the precise onset, peak, and lingering of every note (sweet, savory, creamy, acidic). We then use this map to build the allergen-free equivalent, ensuring the mouthfeel and flavor release mirrors the target as closely as possible, using layered flavor technology [2.5].

To support client claims, our flavors undergo rigorous internal and external validation:

Specialized ingredients, dedicated manufacturing, and rigorous testing inherently increase the cost of “Free From” products, a key market inhibitor [4.2]. We work with clients to develop Cost-In-Use Optimization strategies, utilizing highly concentrated, high-impact flavor systems to minimize dosing, thereby improving margins without compromising the critical safety or sensory experience.

The “Free From” movement represents not a limitation, but a revolution in food technology. It has pushed the flavor industry to new heights of molecular precision, supply chain integrity, and sensory innovation.

For manufacturers targeting this segment—whether to address medical necessity or lifestyle choice—the flavor experience is the ultimate gatekeeper. The promise of safety without sacrificing deliciousness is the key to unlocking the full potential of this multi-billion-dollar market.

At CUIGUAI Flavor, we are the technical partner dedicated to solving the complex flavor matrix challenges of allergen-conscious products, turning constraints into culinary masterpieces.

Safe, Inclusive Snacking

Don’t let the technical challenges of “Free From” formulation compromise your product’s taste. Leverage our expertise in flavor masking, dairy replacement, and certified allergen-free manufacturing.

[CTA Button] Request a Technical Exchange to Discuss Allergen-Free Flavor Systems or Request a Free Sample Kit of Our Certified Dairy-Free Cheese Flavors

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.