The Global Network

The modern food and beverage industry faces a unique and profound challenge: the need to build brands with a globally scalable identity while simultaneously creating products that are hyper-localized to resonate with specific regional tastes. A flavor that is a blockbuster hit in one market can be a complete and utter failure in another. The classic “one-size-fits-all” approach to flavor, once the standard for global expansion, is now a relic of the past.

The reason for this is the immense complexity of culinary culture. Taste preferences, regulatory frameworks, ingredient associations, and even the emotional connection to food are deeply ingrained in a region’s history and heritage. Simply taking a flavor and launching it in a new country is a high-risk, low-reward gamble.

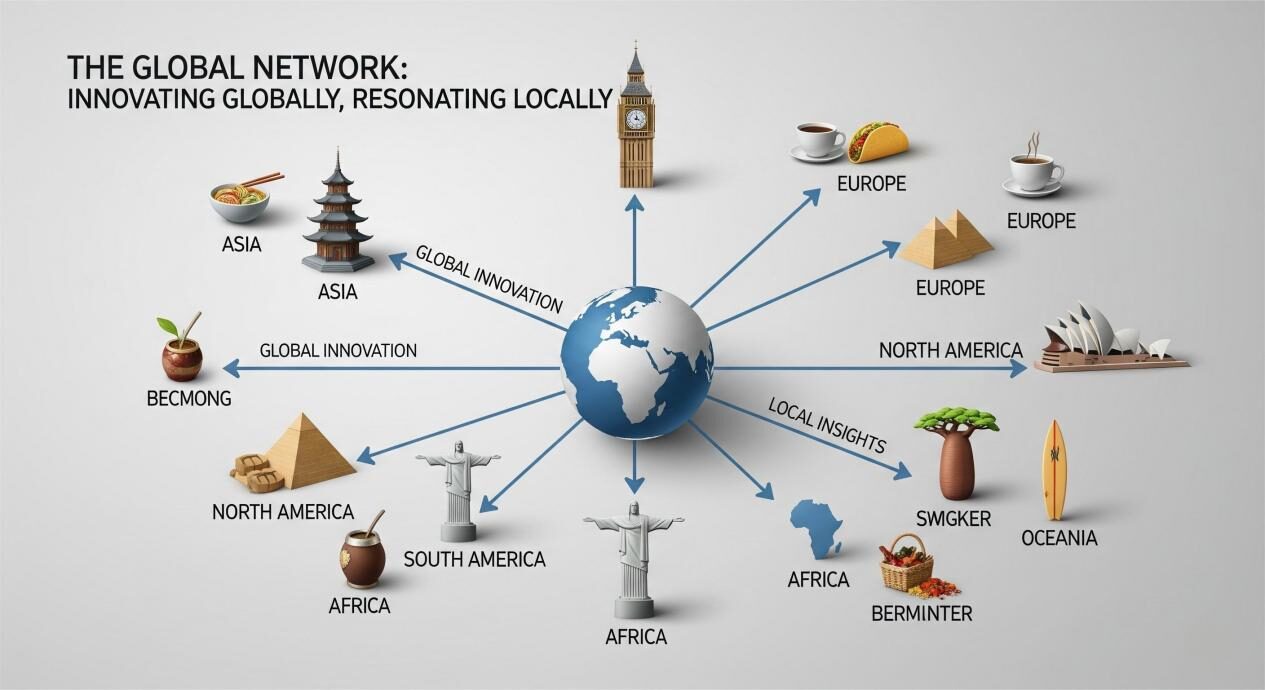

Leading global flavor manufacturers have solved this paradox. They’ve moved beyond the traditional model of centralized R&D and have built sophisticated, decentralized networks that combine a core of cutting-edge innovation with agile, on-the-ground, local teams. This model allows them to provide a seamless, end-to-end service, delivering localized food-grade solutions with the scale, security, and innovation of a worldwide leader. This comprehensive technical guide will delve into the complexities of the global-local paradox, detail the organizational blueprints that solve it, and analyze the profound commercial advantages of this new era of flavor service.

Expanding a product across borders involves navigating a labyrinth of challenges, most of which can only be addressed with a deep understanding of the local market.

Taste is not universal. What is considered a pleasing flavor profile in one country can be unappealing in another.

The regulatory landscape is arguably the most significant hurdle for global expansion.

Even if a product is perfectly formulated, getting it to the manufacturer can be a challenge.

A 2023 study in the Journal of International Marketing highlighted that a lack of cultural and regulatory localization is a primary reason for global product failures, underscoring the need for a targeted, localized approach to product development (Reference 1: J. Int. Mark., 2023, “The Cultural and Regulatory Challenges of Global Food Product Launches”).

The most advanced flavor manufacturers have built a sophisticated organizational model that elegantly solves the global-local paradox. This model is built on a foundation of three interconnected pillars.

At the heart of a global flavor company is a centralized R&D hub. This core team is responsible for:

This core ensures that the entire company operates on a foundation of scientific excellence and innovation.

Radiating from the global core are regional innovation centers, each a hub of local expertise.

On the front lines of customer service are local application labs.

The International Organization of the Flavor Industry (IOFI) has highlighted this decentralized model as a best-in-class approach for ensuring both global innovation and local relevance in a complex market (Reference 2: IOFI, 2024, “Trends in Global Flavor Innovation and Supply Chain Management”).

A Global Footprint, A Local Touch

A partnership with a global flavor manufacturer is a collaborative, systematic process that ensures a successful product launch in any market.

The process begins with the flavor house’s local team conducting in-depth market research. They analyze local food trends, visit local markets, and conduct sensory mapping sessions with a trained panel of local consumers. This data provides a detailed “sensory fingerprint” of the market, which serves as the foundation for the entire project.

The manufacturer provides a product brief. The local flavorist then takes a concept from the global library—for example, a new caramel flavor—and adapts it. This might mean adding a more buttery note for the European market, a roasted, savory note for the Asian market, or a more subtle, milky note for a market in Latin America. The team uses the sensory mapping data to ensure the final profile will resonate with local palates.

The local team works with locally sourced ingredients, which not only ensures authenticity but also reduces supply chain risk and cost. They then test the adapted flavor in a local food matrix, using the same ingredients and processing methods that the manufacturer will use. This ensures that the flavor performs perfectly in the final product.

The local application team works directly with the manufacturer to conduct pilot-scale production runs. The flavorists and application scientists can be on-site to assist, providing guidance on dosing and mixing to ensure a seamless transition to commercial scale. This hands-on, localized support is a critical factor in a successful product launch.

The investment in a global-local model provides a powerful strategic advantage for manufacturers, directly impacting their bottom line and brand reputation.

A global flavor partner allows a manufacturer to maintain a consistent core brand identity (e.g., a consistent cola profile) while tailoring the flavor for local success (e.g., a less carbonated, sweeter profile for a specific regional market). This is the key to balancing global branding with local consumer needs.

Entering a new market is a high-risk endeavor. A partnership with a global flavor company mitigates these risks, particularly in terms of regulatory compliance and product acceptance. The local team’s expertise ensures that the product is legally compliant and that the flavor will be a commercial success. A 2023 European Food Safety Authority (EFSA) report highlighted the complexities of regional food regulations and the importance of expert guidance for compliance (Reference 3: EFSA, 2023, “Food Additive Regulations and Safety Evaluation in the EU”).

The localized support model drastically reduces the time and cost of R&D. Instead of a manufacturer needing to spend months or years navigating a new market’s taste and regulatory landscape, they can leverage the flavor house’s existing network and expertise to accelerate the product development cycle.

A global flavor network provides a secure, redundant supply of ingredients. If a regional supply chain is disrupted—due to a natural disaster or geopolitical event—the global network can step in to ensure a continuous supply of ingredients, protecting the manufacturer from production halts. A 2024 Bloomberg article noted that the resilience of a company’s supply chain is a key differentiator in a world of increasing disruption, making a global flavor partner a strategic asset (Reference 4: Bloomberg, 2024, “Building Resilient Global Food Supply Chains”).

The Promise of Precision: The Taste of Excellence

The “global-local paradox” is a challenge that has been solved by the most advanced flavor manufacturers. They have moved beyond a centralized, one-size-fits-all model and have created a powerful, decentralized network that combines global innovation with hyper-localized service.

This model empowers food manufacturers to innovate, scale, and succeed in any market around the world. It provides the deep cultural insights to create flavors that resonate, the regulatory expertise to ensure compliance, and the technical support to guarantee flawless application. The future of global food innovation is not a solitary journey but a collaborative one, where the power of a global flavor partner is the key to unlocking success in every market.

Keywords: global flavor supplier, international flavors, local service, worldwide reach

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Sep 17, 2025

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.