Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 20, 2025

Modern Flavor R&D Lab

In food and beverage development, aroma is the invisible architect of flavor. Although consumers often talk about “taste,” scientific research indicates that up to 80% of what people perceive as taste actually comes from aroma, not the tongue alone. Taste can only detect sweet, sour, salty, bitter, and umami—everything else that creates the experience of strawberry, chocolate, coffee, vanilla, or citrus is driven by volatile aroma molecules.

The power of aroma is so significant that the U.S. National Institutes of Health notes that olfaction plays a central role in food enjoyment and emotional responses². In the competitive food industry, the ability to engineer irresistible aromatic profiles increasingly determines product success, brand loyalty, and market differentiation.

In this comprehensive 3000+ word article, we explore the science, techniques, chemistry, psychology, and manufacturing innovation behind aroma creation—specifically for food and beverage applications. From molecular design to sensory analysis, from fermentation volatiles to aroma release kinetics, this guide provides deep technical insights designed for food scientists, product developers, and formulation teams.

As a professional manufacturer of food and beverage flavorings, we bring both scientific rigor and industry experience to this topic, enabling your team to better understand how aromas are crafted and how they can be applied to accelerate product success.

Aroma perception begins when volatile molecules enter the nose and bind to approximately 400 types of human olfactory receptors. Each receptor is tuned to detect specific structural patterns—esters, aldehydes, heterocyclic compounds, pyrazines, lactones, terpenes, ketones, and more.

The human olfactory system operates on a combinatorial coding model, meaning each odorant activates multiple receptors, and each receptor responds to multiple odorants. According to the U.S. National Library of Medicine, this combinatorial pattern is interpreted by the brain to generate the perception of a specific aroma⁴.

This is why:

The science of aroma, therefore, requires precise understanding of chemical structures and perceptual outcomes.

The main aromatic molecule classes include:

Common in fruits like apple, pineapple, banana, peach, and strawberry. They are formed through esterification reactions between alcohols and acids. Esters often provide sweet, juicy, fruity character.

Strong contributors to green, citrus, and fresh notes. For example:

Provide buttery, creamy, and dairy notes.

Examples: diacetyl, acetoin, delta-decalactone.

Responsible for herbal, floral, citrus, and tropical notes.

Examples: limonene, linalool, geraniol.

Key for roasted, nutty, earthy, coffee, or cocoa aromas.

Examples: 2,3,5-trimethylpyrazine, 2-ethyl-3,5-dimethyl pyrazine.

Very potent, often used at extremely low levels to create savory, onion, garlic, meaty, or tropical nuances.

These compounds interact synergistically, requiring precise formulation to achieve desirable flavor expression.

There are two different aroma pathways:

Retronasal aroma is what consumers typically interpret as “flavor.” For example, the flavor of strawberry yogurt, cola, coffee, or chocolate is predominantly retronasal aroma integrated with sweetness, acidity, texture, and temperature.

Understanding both pathways is essential for aroma engineering, especially in:

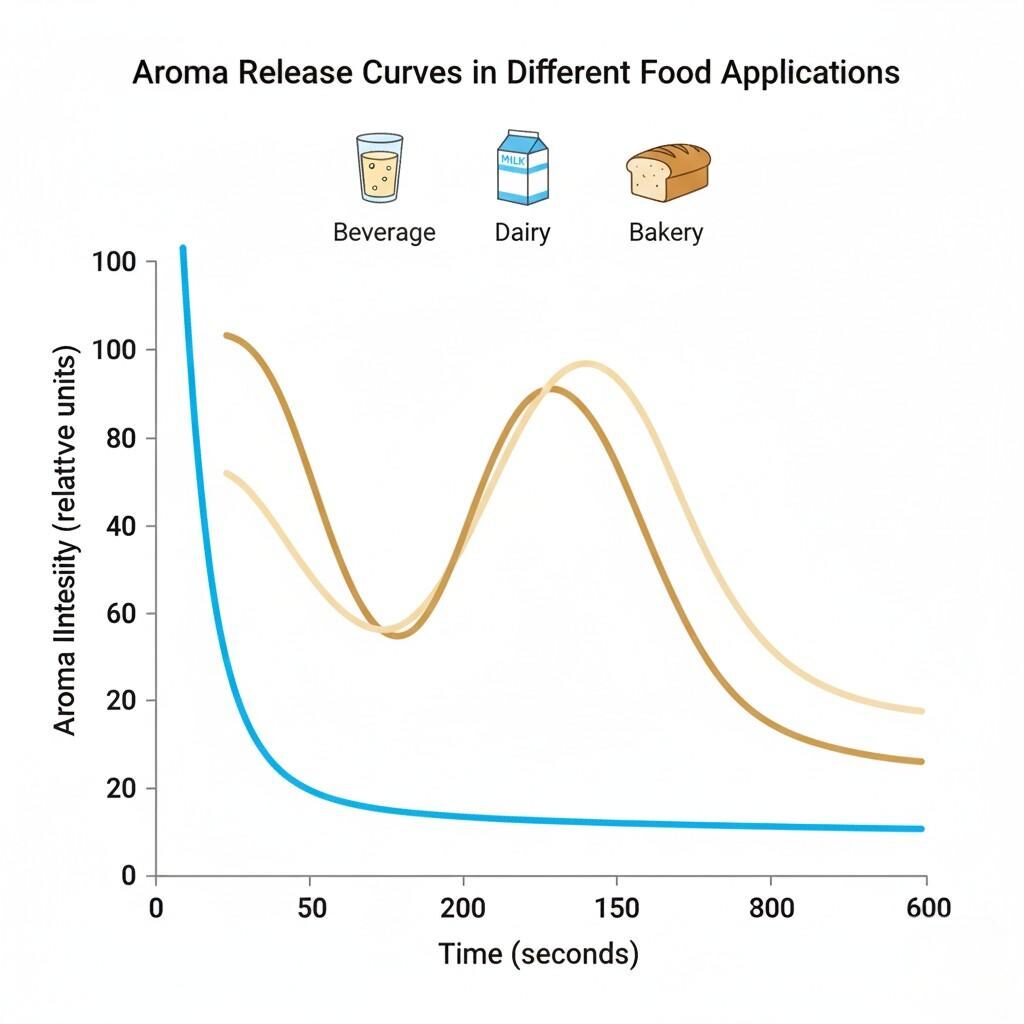

Low-molecular-weight compounds (e.g., esters) volatilize quickly, generating strong top notes.

Higher-molecular-weight molecules release slowly, contributing to mid notes and base notes.

Aroma molecules interact differently with:

This is why the same flavor can smell very different in:

Aroma release increases exponentially with temperature.

Hot products like soups, teas, and bakery items generate more intense aromatic impact.

To stabilize aroma in beverages or dairy products, flavor chemists use emulsifiers (gum arabic, OSA-starch, pectin, modified gums) to control:

These technical design steps ensure that drinking a beverage provides consistent sensory experience from start to finish.

High-quality aromatics come from:

GC–MS (Gas Chromatography–Mass Spectrometry) identifies the chemical composition of aroma, while GC–O (Gas Chromatography–Olfactometry) determines which compounds contribute most to perceived aroma.

This combination allows scientists to reconstruct complex aromas—like passionfruit or roasted coffee—by focusing on active aroma compounds rather than all volatiles present.

A professional flavor formula generally includes:

Flavor chemists design these layers carefully to create complexity and realism.

The design goals depend on application:

Crafting aroma is both a science of molecules and an art of sensory balance.

Aroma Release Curves Diagram

Challenges:

Solutions:

Dairy systems bind aroma through protein interactions, especially casein and whey proteins.

Plant-based matrices complicate aroma release due to:

Technical solutions include:

Sugar, fat, and starch create a thick matrix that traps aroma.

Baking also drives Maillard reactions and caramelization, creating new aromatic compounds.

Solutions include:

Savory flavors rely heavily on:

Applications include:

Stability, authenticity, and balanced umami are essential.

The olfactory bulb is directly connected to the amygdala and hippocampus, the parts of the brain responsible for emotion and memory. This is why scent can immediately evoke strong emotional associations. Studies from Harvard indicate that smell triggers memories far more effectively than visual or auditory cues¹.

Cultural background heavily influences aroma preference:

Understanding cultural preference is essential for market targeting.

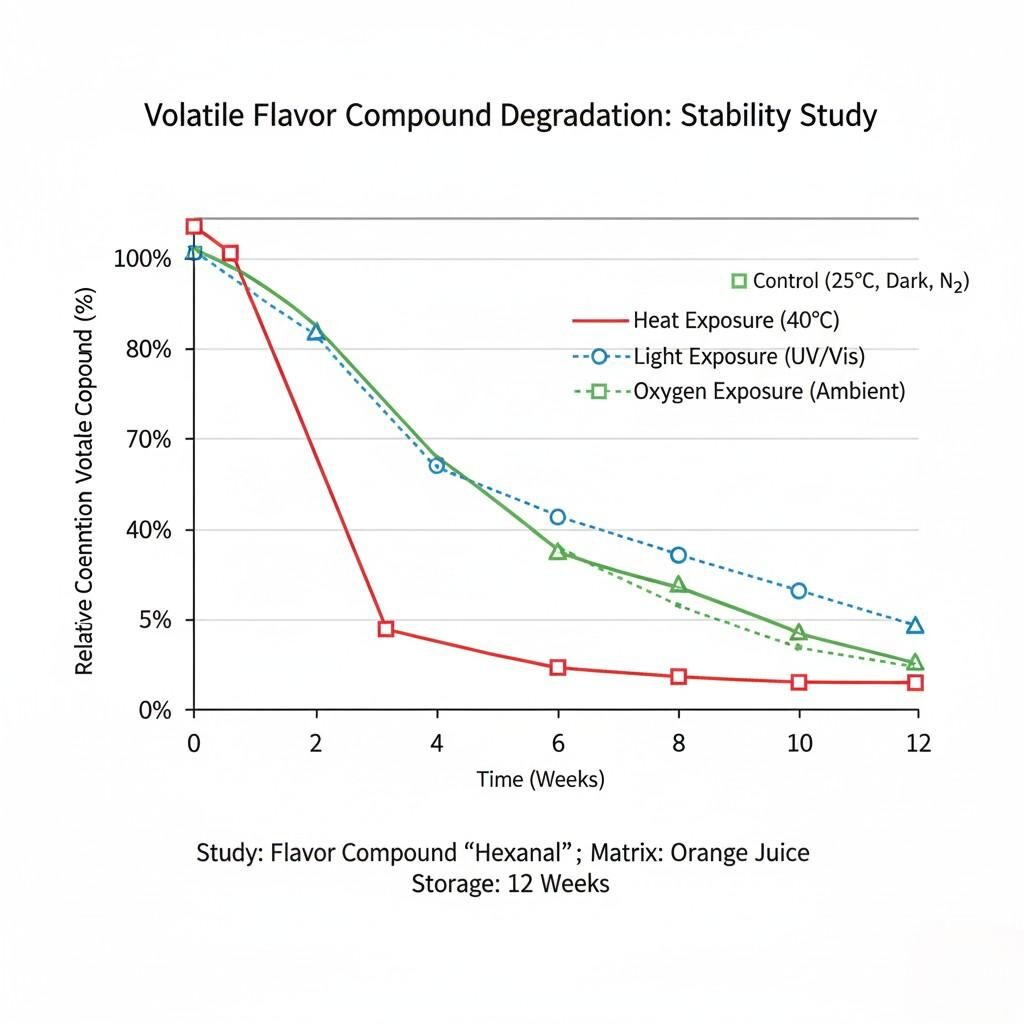

Flavor Stability Study Chart

Aroma molecules—especially aldehydes and terpenes—degrade quickly when exposed to oxygen.

Stabilization strategies:

Flash pasteurization, UHT treatment, or retort processes can degrade flavor unless heat-stable ingredients are used.

Flavors must comply with rules from:

For example, FEMA GRAS publishes safety evaluations used widely in global flavor regulation³.

Fermentation can produce natural aromatic compounds identical to those found in fruits, cocoa, coffee, and dairy. These biogenerated molecules are increasingly popular due to sustainability and clean label benefits.

AI now helps:

Encapsulation allows aromatics to:

As plant-based foods grow in popularity, aroma solutions are essential to:

Professional flavor creation includes:

Understanding consumer expectation gaps.

Reverse-engineering natural aromas.

Building complex, multi-layered aromatic systems.

Ensuring aroma performance in real product conditions.

Simulating real manufacturing environments.

Ensuring global compliance.

Testing for acceptance, realism, and impact.

As a professional flavor manufacturer, we integrate advanced chemistry with sensory science to deliver aroma solutions that help brands stand out in competitive markets.

Aroma is the foundation of flavor perception and one of the most powerful tools in food and beverage innovation. Through deep knowledge of volatile compound chemistry, sensory science, biotechnology, and R&D formulation techniques, brands can create aromatic profiles that differentiate products, elevate consumer enjoyment, and strengthen brand loyalty.

For R&D teams, understanding aroma science is not just beneficial—it is indispensable for success in modern product development.

Flavor Product Development Collage

We specialize in high-performance food and beverage flavorings and aroma modulation technologies. If your team is working on:

We provide free technical consultation and R&D sample support for qualified projects.

Contact us for expert assistance and customized aroma solutions.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.cn]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.