Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 17, 2026

Advanced Beverage Science Lab

The global functional beverage market has shifted from a niche health-food interest to a dominant retail force. At the heart of this revolution is the “fermented” category—led by kombucha, water kefir, and probiotic-fortified seltzers. For the modern consumer, the appeal lies in the perceived “living” nature of the product, the complex tartness, and the promise of gut health. However, for the flavor chemist and product developer, fermentation is one of the most volatile and unpredictable biological processes in the food industry.

Achieving an “authentic” fermented profile that is shelf-stable, consistent across batches, and palatable to a broad audience requires more than just biological luck; it requires advanced flavor science. As a professional manufacturer of food and beverage flavorings, we recognize that the challenge isn’t just adding a “peach” or “ginger” top-note. The challenge is respecting the underlying chemistry of the ferment while managing the aggressive organic acids and sulfurous off-notes that naturally occur during production. This guide explores the technical intricacies of flavoring fermented and probiotic products for the commercial market.

To recreate or enhance fermented flavors, we must first deconstruct the chemical fingerprint of a natural ferment. In kombucha, this is the result of the Symbiotic Culture of Bacteria and Yeast (SCOBY). This biological factory produces a “metabolome”—a vast array of small-molecule metabolites that define the sensory experience.

The primary sensory driver of fermented products is the organic acid profile. Unlike a standard soft drink, which might rely solely on citric or phosphoric acid (H3PO4) for tartness, fermented teas possess a complex “acid broth.” The ratios of these acids dictate the “sharpness” or “smoothness” of the palate:

Beyond the acids, the “funk” of fermentation comes from volatile compounds. Research published in the Journal of Food Science and Technology highlights that the characteristic aroma of kombucha is a result of a delicate balance between alcohols, esters, and aldehydes. According to the Wikipedia entry on Kombucha, the fermentation process produces a variety of these compounds, including ethyl acetate (reminiscent of pear/fruit at low levels) and isoamyl alcohol.

Authentic flavor solutions must mimic or harmonize with these “funky” esters to feel genuine. If a flavor is too “clean,” the consumer perceives it as a standard soda with vinegar added, rather than a true fermented beverage.

While a home-brewed kombucha can afford to be inconsistent, a commercial product cannot. Scaling fermented products introduces three primary flavor hurdles: Alcohol Management, Stability, and Off-note Development.

In the United States and many other regions, a product labeled “non-alcoholic” must remain below 0.5% ABV (Alcohol by Volume). Because fermentation is a living process, yeast continues to produce ethanol (C2H5OH) after bottling if residual sugar is present.

To stay compliant, manufacturers often use “arrested fermentation,” filtration, or spinning cone columns to remove alcohol. However, these methods often strip away the very esters and top-notes that make the drink authentic. This is where fermentation-derived flavorings become essential. We can provide the “yeasty” and “ethanol-like” sensory cues through flavoring without adding actual alcohol content, restoring the soul of the beverage that was lost during processing.

Commercial fermentation can sometimes run away, leading to excessive acetic acid. This not only affects taste but also the stability of other added ingredients. High acidity can cause certain natural colors to shift (e.g., anthocyanins turning bright red) or cause proteins to precipitate. Technical flavor modulation can “round off” the sharp edges of acetic acid using sweetness enhancers or kokumi flavors that provide a savory depth, effectively masking the “vinegar burn” in the throat without raising the pH.

Probiotic products, particularly those fortified with Bacillus coagulans or other spore-forming bacteria, often suffer from sensory defects that arise either from the bacteria themselves or the media they are grown in.

Certain yeast strains or stressed bacteria can produce hydrogen sulfide (H2S) or mercaptans. These result in “rotten egg” or “earthy/musty” aromas. In a light, fruity seltzer, these notes are catastrophic.

Our Solution: We utilize specialized sulfur-masking technology. This doesn’t just “cover” the smell with more perfume; it uses aromatic antagonists. These are molecules that compete for the same olfactory receptors as the sulfur compounds, effectively “blinding” the nose to the off-note while allowing the “bright” notes of the fruit components (like linalool in citrus or ethyl butyrate in pineapple) to dominate.

Since kombucha is tea-based (Camellia sinensis), high concentrations of polyphenols can lead to a dry, puckering mouthfeel. When combined with high acidity, this can be overwhelming. Flavorists use “bitterness blockers” that bind to the T2R taste receptors on the tongue. By preventing the bitter signal from being sent to the brain, we can create a “smoother” tea base that serves as a better canvas for delicate fruit flavors.

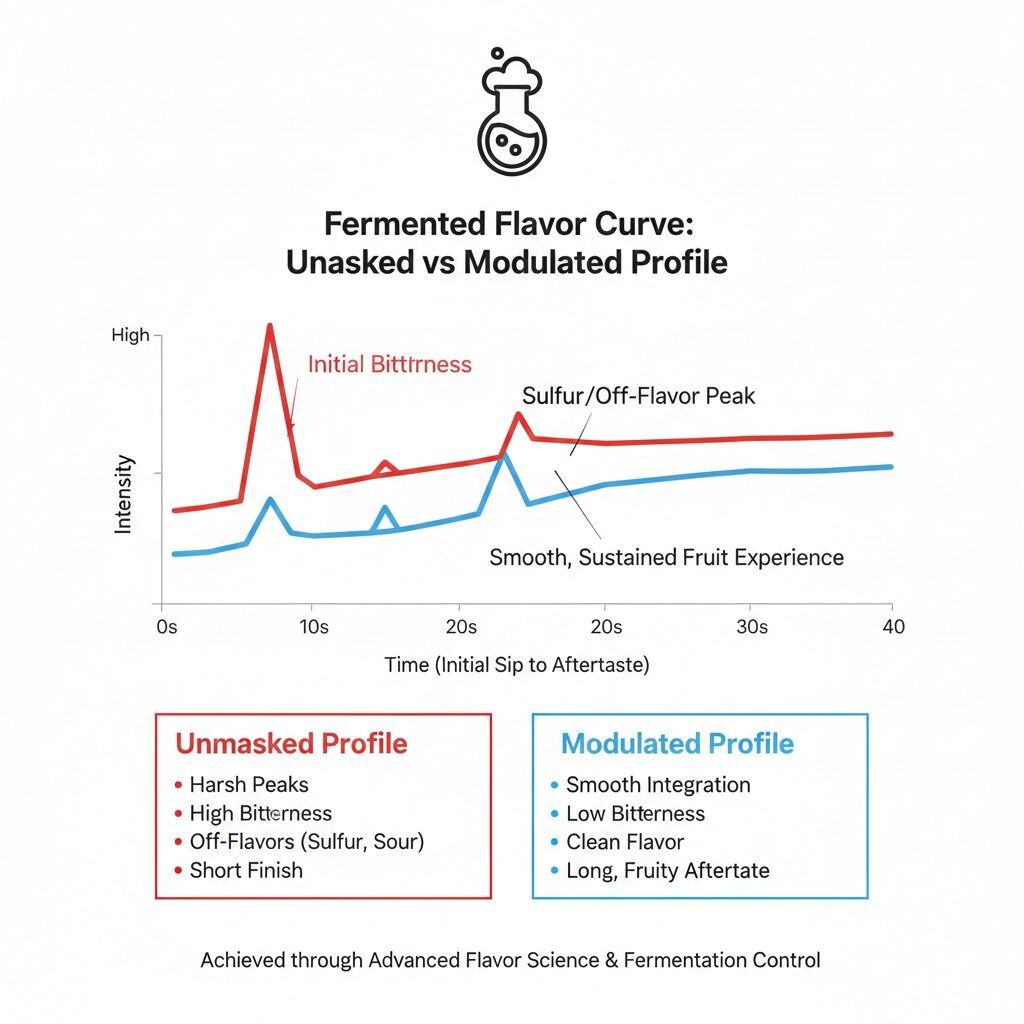

Beverage Flavor Curve Infographic

In traditional brewing, the “second fermentation” is when fruit and botanicals are added. In the commercial world, this is where the brand identity is built. The flavor system must be designed to work with the ferment, not against it.

Citrus profiles (Lemon, Ginger, Grapefruit, Yuzu) are the most popular for a reason. Their natural acidity (citric acid) complements the fermented base.

Berries (Raspberry, Blackberry, Strawberry) are notoriously difficult. The “green/seedy” notes of a natural berry flavor can clash with the “earthy” notes of the tea.

The trend of adding Ashwagandha, Turmeric, or Lion’s Mane introduces new bitterness. According to Kombucha Brewers International (KBI), the integration of functional botanicals is a top growth driver, but it requires precise taste modulation (Kombucha Brewers International).

The most common complaint from beverage manufacturers is that their product “tasted great at the lab bench but lost its punch after three months in the warehouse.” Fermented bases are chemically aggressive. The low pH (often between 2.5 and 3.5) can cause many flavor molecules to undergo acid-catalyzed hydrolysis.

For example, a “lemon” flavor relying on citral will quickly degrade into p-cymene in a low-pH environment, resulting in a “furniture polish” or “turpentine” off-note.

To combat this, we utilize advanced emulsion technology. By encapsulating volatile flavor oils in a protective matrix (often using modified food starches or natural gums), we can:

A significant sub-sector is the “probiotic seltzer”—clear, carbonated waters with added probiotics (Bacillus coagulans) but no actual fermentation. These products are popular because they are zero-calorie and easy to produce. However, they often lack the “soul” of a fermented drink.

For manufacturers who want the “health halo” of a fermented product without the manufacturing complexity, we have developed Fermentation-Mimic Systems. These are flavor systems that provide:

This allows for a “Kombucha-style” seltzer that is 100% consistent and contains zero alcohol, meeting the needs of the “sober-curious” and “clean-label” consumer.

Flavor is not just an olfactory event; it is a tactile one. A real kombucha has a certain “weight” on the tongue caused by residual sugars and long-chain polysaccharides produced by the bacteria.

When developers create “Low Sugar” or “Zero Sugar” fermented drinks, they lose this body, leaving the drink tasting “thin” or “watery.” We utilize Kokumi modulators. Kokumi, a Japanese term for “heartiness” or “mouth-fullness,” involves compounds (like specific peptides) that interact with the calcium-sensing receptors on the tongue.

By adding a Kokumi-based flavor, we can:

Effervescent Kombucha Splash

In the functional beverage space, “Natural” is the baseline. Under FDA guidelines (21 CFR 101.22), any flavor labeled as natural must be derived from a spice, fruit, vegetable, edible yeast, herb, bark, bud, root, leaf, or similar plant material.

Many fermented brands are certified Organic. This requires the flavorings to be Organic Compliant (using only approved carriers like organic ethyl alcohol or organic sunflower oil) or Certified Organic (where 95% of the flavor components themselves are organically grown).

As noted by the World Health Organization (WHO) in their guidelines on food safety and additives, the integrity of the supply chain is paramount. We provide full documentation—from GC-MS breakdowns to Non-GMO Project Verification—ensuring that your “clean label” stands up to the most rigorous audits.

It is also vital to ensure that flavor components do not inhibit the “colony forming units” (CFUs) of the probiotics. Some essential oils have antimicrobial properties (e.g., oregano oil or high levels of cinnamon oil). We conduct compatibility testing to ensure that our flavor systems do not negatively impact the “living” count of your probiotic strains over the product’s shelf life.

The next frontier in this industry is precision fermentation—using genetically modified yeast to produce specific flavor molecules (like “Natural Vanillin” or “Nootkatone”) in a vat.

Furthermore, the use of “rare sugars” like Allulose or Tagatose is changing the fermentation landscape. These sugars provide the bulk and browning of sucrose but are not metabolized by the body in the same way. However, they also ferment differently. Our R&D team is currently studying how these new sweeteners interact with traditional flavor systems to ensure that the “allulose-sweetened kombucha” of the future tastes exactly like the traditional version.

Creating a successful fermented or probiotic beverage is a high-wire act. You must balance the wild, unpredictable nature of a biological ferment with the rigid requirements of commercial retail: stability, consistency, and exceptional taste.

Standard “off-the-shelf” flavors are rarely sufficient for the complex, acidic, and volatile matrix of a fermented drink. Success requires a layered flavoring approach:

As a professional flavor manufacturer, we act as an extension of your R&D team. We don’t just sell flavor; we solve the biological puzzles that stand between your concept and a market-leading product. The future of the beverage aisle is functional, and the foundation of that functionality is flavor. Let’s build it together.

Urban Wellness Kombucha Lifestyle

Are you facing challenges with flavor stability, high acidity, or unappealing off-notes in your fermented beverage line? Experience the difference that technical expertise makes.

We invite you to a Technical Exchange:

Request a Technical Consultation & Free Sample Kit

Partner with us to turn biological complexity into sensory excellence. Your gut-health revolution starts with great taste.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.