Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Dec 02, 2025

Before & After Flavor Transformation

In the dynamic and highly saturated food and beverage market, flavor is the single most critical factor determining product success, repeat purchase, and brand longevity. It is the core of the consumer sensory experience and the most powerful driver of emotional connection to a brand.

However, modern product development is fraught with complex technical challenges: the global push for clean labels (reducing sugar, salt, and artificial ingredients), the need to incorporate challenging functional ingredients (like plant proteins and prebiotics), and the relentless pressure to maintain flavor stability across diverse processing matrices.

As professional flavor manufacturers, our role extends beyond simply supplying concentrates; we act as technical partners, utilizing advanced flavor chemistry to solve these real-world business problems. This blog post explores three technical case studies demonstrating how targeted flavor innovation and collaboration transformed product challenges into market triumphs, illustrating the principle that technical finesse equals commercial success.

A major client specializing in ready-to-drink (RTD) functional beverages approached us with a significant problem: their new line of high-protein, plant-based shakes was suffering from poor consumer acceptance. The product was nutritionally excellent, featuring a high concentration of pea and rice protein isolates.

The technical challenge was the intrinsic off-flavor of the protein source. Plant-based proteins, particularly pea and soy, contain amino acid and peptide compounds that trigger T2R bitter receptors on the tongue, often compounded by earthy, beany, or cardboard notes from lipid oxidation products (Source 2.5, 2.3). The client’s initial masking attempts, which relied heavily on excessive sucralose and high-dose vanilla, resulted in an artificial, sweet-and-bitter profile that was failing consumer sensory tests. They needed a clean-label flavor system that eliminated the off-notes while maintaining a low sugar/sweetener count.

Our approach was not to mask, but to use a multi-layered flavor modulation strategy to chemically and physically interact with the off-note compounds (Source 2.1).

The reformulated product achieved a 95% flavor consistency rating in panel tests compared to the original, highly sweetened benchmark, and successfully secured a Series A funding round for the client, with taste being cited as a key commercial asset (Source 1.3). The use of the clean-label flavor modulator allowed the client to reduce total added sugar equivalents by over 40%, meeting the critical nutritional transparency demands of the modern consumer (Source 1.2).

Controlled Flavor Release in Baking

A beverage company aimed to launch a clear, functional sparkling water line infused with natural citrus flavors (lemon, lime, grapefruit) and vitamins. The core technical hurdle was flavor stability during the product’s 12-month shelf life.

Citrus flavors, primarily composed of volatile monoterpenes like Limonene and Citral, are highly susceptible to oxidation, especially when dissolved in an aqueous, low-pH, and oxygen-containing matrix, like carbonated water. Within six months, the client’s prototypes developed a noticeable pine-needle or turpentine off-flavor, a classic sign of terpene oxidation (Source 3.4). Furthermore, the client required the final product to be crystal clear, which ruled out traditional, cloud-forming flavor emulsions, which often provide better stability (Source 3.2).

We collaborated with the client to develop a Clear, High-Stability Flavor System using a combination of technical stabilization methods:

The final product maintained perfect visual clarity and 98% flavor retention over the targeted 12-month shelf life. This technical achievement allowed the client to successfully enter the premium clear beverage market, where visual clarity and flavor consistency are paramount to consumer perception of quality and freshness (Source 3.5). The success demonstrated that stability is not just about taste, but about protecting the integrity of the total product sensory experience.

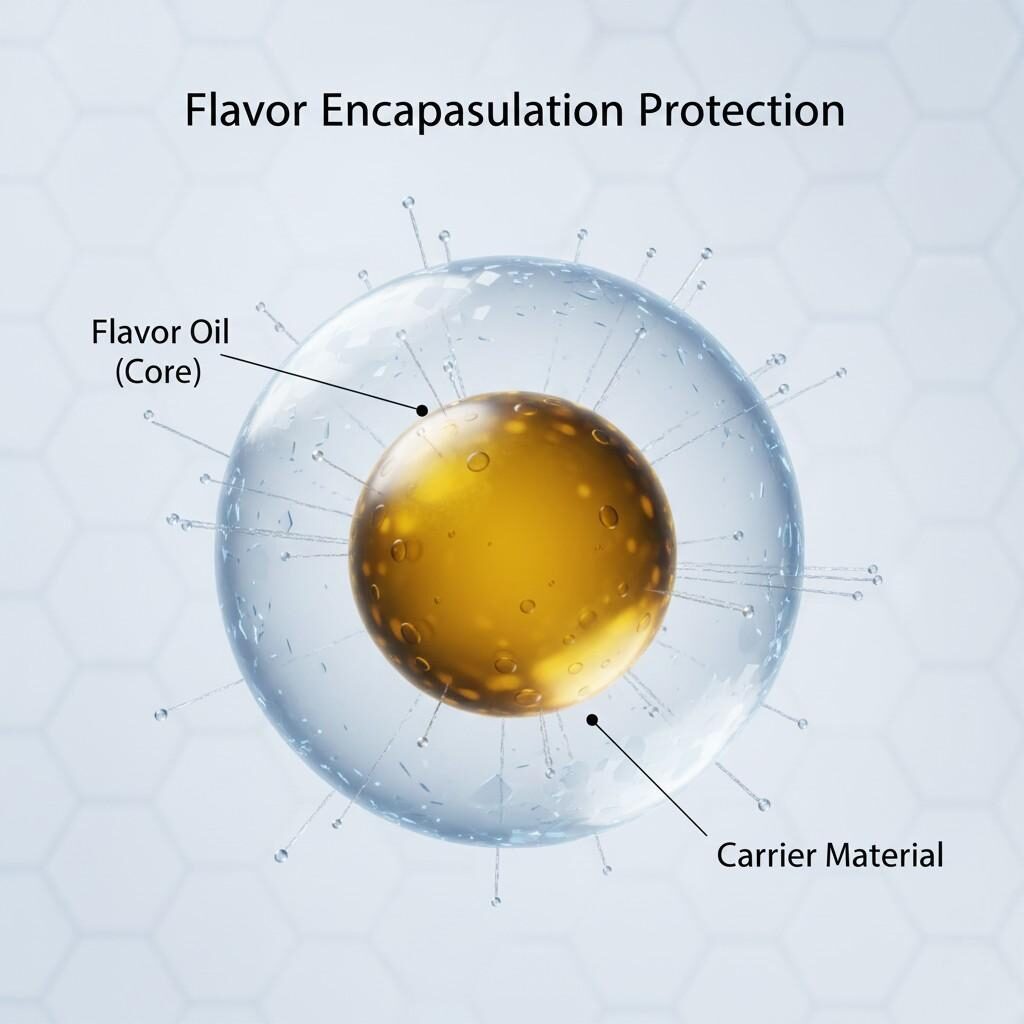

Flavor Encapsulation Protection

A wholesale bakery manufacturer faced a dual challenge in their best-selling sweet morning rolls, driven by public health initiatives (Source 1.1):

The solution required tackling the issues with both technical and sensory adjustments:

The bakery successfully implemented both the sodium reduction and the natural vanilla replacement. Detailed sensory testing at an educational institution confirmed that the new formulations maintained both the texture and the essential taste characteristics of the original (Source 1.1). The use of encapsulated flavors allowed the client to achieve 100% clean-label compliance on the vanilla ingredient, future-proofing their product line against increasing consumer demand for natural ingredients. This strategic reformulation allowed the client to win new tenders with health-conscious customers (Source 1.1).

These case studies underscore a fundamental truth in the food and beverage industry: Flavor success is a function of applied science. Whether the challenge is mitigating the bitterness of alternative proteins, preventing the oxidation of volatile citrus oils, or protecting delicate flavor notes from high-temperature processing, the solution lies in a deep understanding of flavor-matrix interaction and advanced technical tools like flavor encapsulation, modulation, and analytical validation (GC-MS).

The era of simple flavor sourcing is over. The competitive landscape demands a strategic partnership with a flavor manufacturer who can translate complex technical hurdles into commercial opportunities. By focusing on precision formulation and stability, we don’t just solve problems; we co-create market leaders.

Flavor Partnership Agreement

Is your product facing a stability, off-note, or clean-label challenge? Stop compromising on taste.

We invite your R&D team to a Technical Exchange with our flavor chemists to discuss your specific product matrix. Request a free, custom-engineered flavor sample designed to solve your toughest technical hurdles.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.cn]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.