The Path to Flavor Perfection

In the fiercely competitive world of food and beverage manufacturing, a product’s success is often decided in a single moment: the first taste. Flavor is not merely an attribute; it is the primary driver of consumer choice, brand loyalty, and repeat purchases. A great flavor can build an empire, while an uninspired or inconsistent one can lead to a product’s swift decline.

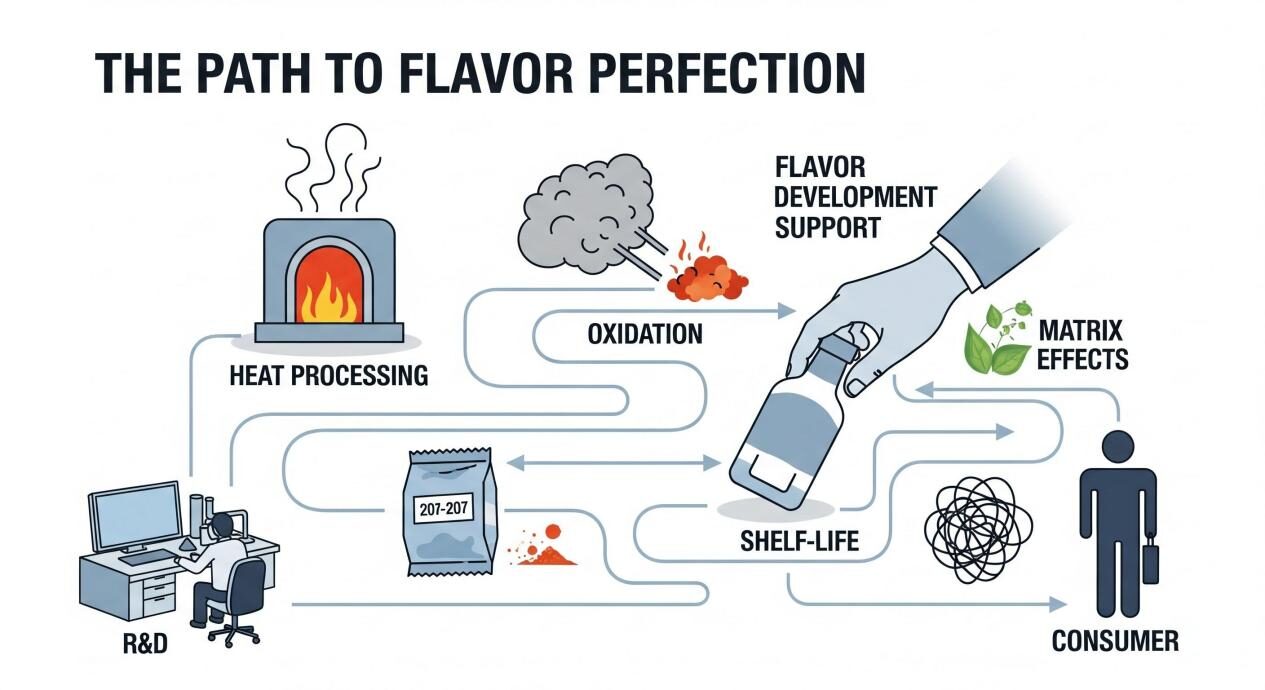

The journey from a brilliant flavor concept in a chemist’s vial to a consistently perfect flavor in the final packaged product is fraught with complexity. The food matrix itself is a dynamic, often hostile, environment for delicate aroma compounds. Processing methods like pasteurization, baking, or extrusion can strip away volatile notes. Long-term storage can lead to flavor degradation. These challenges are often a labyrinth that manufacturers, no matter how skilled, must navigate.

This is where flavor development support becomes not a luxury, but a strategic imperative. A partnership with a leading flavor house provides manufacturers with the deep technical expertise, advanced analytical tools, and collaborative guidance needed to overcome these challenges. This indispensable support ensures that a product’s flavor profile achieves optimal performance and remains consistent from the R&D lab to the consumer’s plate. This comprehensive guide will explore the technical complexities of flavor application, detail the core pillars of expert support, and analyze the profound commercial benefits of a robust collaborative partnership.

To understand the value of expert support, we must first appreciate the many ways a great flavor can be compromised during the journey from concept to consumer.

A flavor in isolation behaves very differently than a flavor integrated into a complex food matrix. The final product’s composition—be it fats, proteins, carbohydrates, or water activity—can have a profound impact on flavor perception.

Modern food manufacturing relies on highly efficient, high-speed processing methods. These processes, while necessary for safety and scale, can be brutal on delicate flavor compounds.

Even after a product is manufactured, the battle for flavor integrity continues.

A 2023 study in the Journal of Food Science noted that the interplay between a food’s matrix, its processing, and long-term storage conditions is a primary cause of flavor failure in new product launches, highlighting the need for a holistic approach to flavor management (Reference 1: J. Food Sci., 2023, “Matrix-Flavor Interactions and Flavor Stability in Food Systems”).

A partnership with a leading flavor house goes far beyond simply purchasing a flavor. It is a collaborative relationship built on a foundation of deep technical expertise and a suite of specialized services designed to ensure success.

The first pillar of support is providing expert guidance on how to properly apply a flavor to a specific product.

Ensuring long-term flavor performance is a key part of the support process.

When a problem arises—be it an off-note or a loss of flavor intensity—a flavor house acts as a forensic scientist.

Navigating the complex and ever-changing world of food regulations is a major challenge for manufacturers.

The Flavor Troubleshooting Blueprint

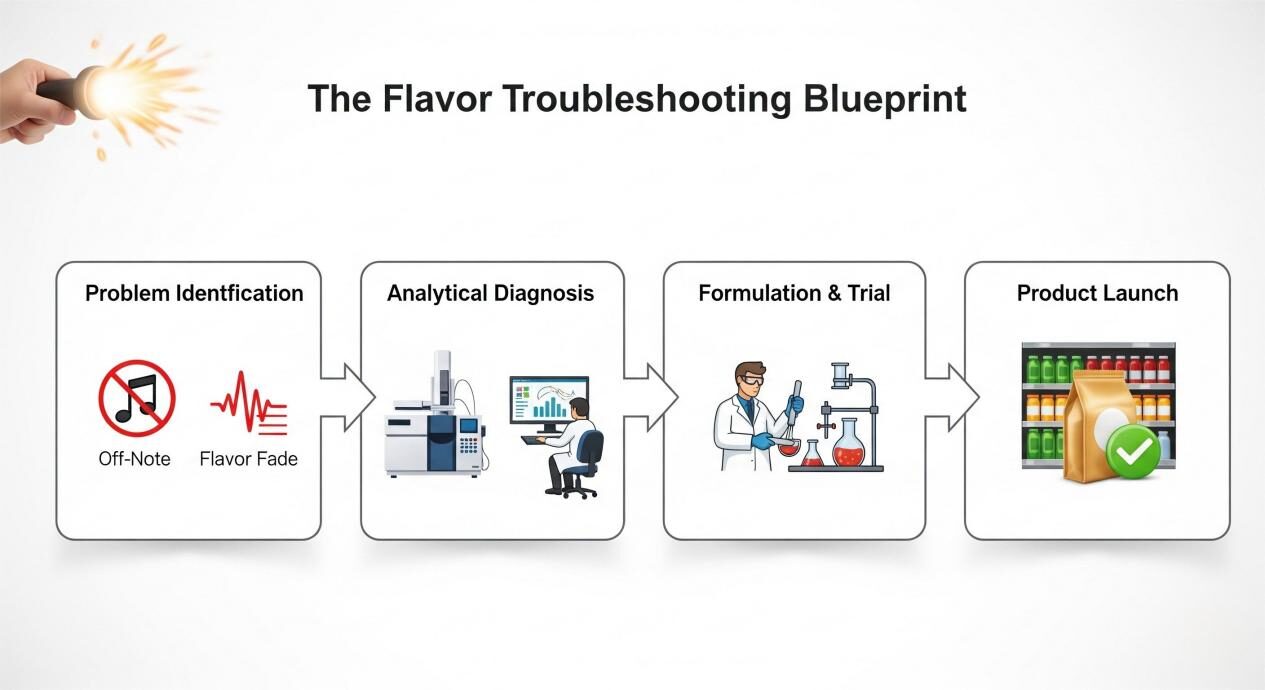

The best flavor development support is not a one-time transaction but a collaborative, step-by-step partnership. Here is a practical blueprint of how this partnership works in practice.

The process begins with the manufacturer providing a product brief and a sample of the product that is experiencing a flavor issue. The flavor house’s team of application scientists and sensory experts conducts a thorough initial audit. They taste and smell the product, noting any off-notes or flavor deficiencies. Simultaneously, the product is sent to the analytical lab for a GC-MS fingerprint, which provides a baseline chemical snapshot of the flavor profile.

Based on the sensory audit and the analytical data, the team diagnoses the root cause of the problem. For example, the GC-MS may reveal that a key flavor ester has been lost during high-heat processing, or that an off-note is being caused by the breakdown of a specific terpene. The flavor scientists then propose a solution, which could be a revised flavor formula, a new flavor format (e.g., encapsulated flavor), or a change in the application guidance.

The most critical step in de-risking a product launch is a successful pilot-scale trial. The flavor house sends a new flavor sample to the manufacturer’s pilot plant. The application scientists can either provide remote guidance or be on-site to assist with the trial, ensuring the flavor is properly integrated and performs as expected under the manufacturer’s specific processing conditions.

Once a successful pilot run is complete, the flavor house provides support for the final, large-scale production run. They ensure a seamless transition from the small-scale pilot to commercial production, providing guidance on dosing and application to ensure consistency across every batch. The final product is then subjected to a final round of sensory and analytical testing to validate its performance and confirm that it meets the agreed-upon standards.

This collaborative approach drastically reduces the R&D cycle, saving the manufacturer significant time and resources.

Beyond the technical benefits, a partnership with a leading flavor house provides manufacturers with significant strategic advantages that directly impact their bottom line and brand reputation.

In today’s market, a single product failure can have a long-lasting negative impact on a brand’s reputation. A flavor house with a robust quality assurance program ensures that every flavor ingredient is safe, consistent, and of the highest quality. This provides a critical layer of security for the manufacturer and builds consumer trust.

The time between a product idea and its launch on the market is a key factor in a manufacturer’s success. Flavor development support can drastically reduce this time by preventing common pitfalls, troubleshooting issues quickly, and providing expert guidance. This allows a manufacturer to bring a superior product to market faster than its competitors.

A flavor that is inconsistent from batch to batch or that degrades on the shelf can quickly erode consumer trust. The consistency and quality assurance provided by flavor development support are essential for protecting and building a brand’s reputation for excellence.

In a crowded marketplace, flavor is a key differentiator. A superior flavor profile, achieved through expert technical support, can be the deciding factor for consumers choosing one product over another. A 2024 report from Euromonitor International highlighted that product innovation, particularly in flavor and functionality, is a primary driver of consumer purchasing decisions, emphasizing the need for expert support in this area (Reference 4: Euromonitor International, 2024, “Global Trends in Food and Beverage Innovation”).

The Promise of Precision: The Taste of Excellence

Flavor development support is not a one-time service; it is a strategic partnership that provides manufacturers with the expertise and tools to navigate the complexities of flavor application, ensuring their products stand out in a crowded marketplace. It is the bridge between a great idea and a successful product launch.

By collaborating with a leading flavor house, manufacturers can de-risk their R&D, accelerate their time-to-market, and, most importantly, deliver a consistent, high-quality flavor experience that builds consumer trust and loyalty. The future of food innovation is a collaborative one, where the expertise of the flavor partner is just as critical as the vision of the manufacturer.

Keywords: flavor technical support, food manufacturing support, flavor performance, application guidance

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Aug 18, 2025

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.