The Path to Flavor Perfection

In the modern consumer landscape, the demand for convenience is insatiable. Time-strapped individuals and families are increasingly turning to ready meals and convenience foods as a solution for quick, hassle-free sustenance. However, convenience alone is no longer enough. Consumers today expect more; they demand a product that delivers on the promise of a delicious, restaurant-quality taste experience, without the effort of a home-cooked meal.

This presents the ready meal industry with a unique and profound paradox. A product designed for speed and simplicity must still compete on taste with a fresh, chef-prepared dish. The flavor, which is the ultimate driver of consumer satisfaction and repeat purchase, is a critical but fragile component. It is easily compromised by the harsh realities of large-scale food production, from the intense heat of thermal processing to the long, unpredictable journey of shelf-life and storage.

Delivering restaurant-quality taste at scale in ready meals is not an act of magic; it is a precise, technical science. It requires a deep understanding of flavor chemistry, engineering, and application. A strategic partnership with a flavor expert is essential for navigating the complexities of thermal processing, shelf-life stability, and matrix interactions to ensure a consistent, premium flavor experience that can compete with the best of fresh food. This comprehensive guide will explore the technical challenges, detail the innovative solutions, and analyze the strategic imperative of a science-based approach to flavor in the ready meal category.

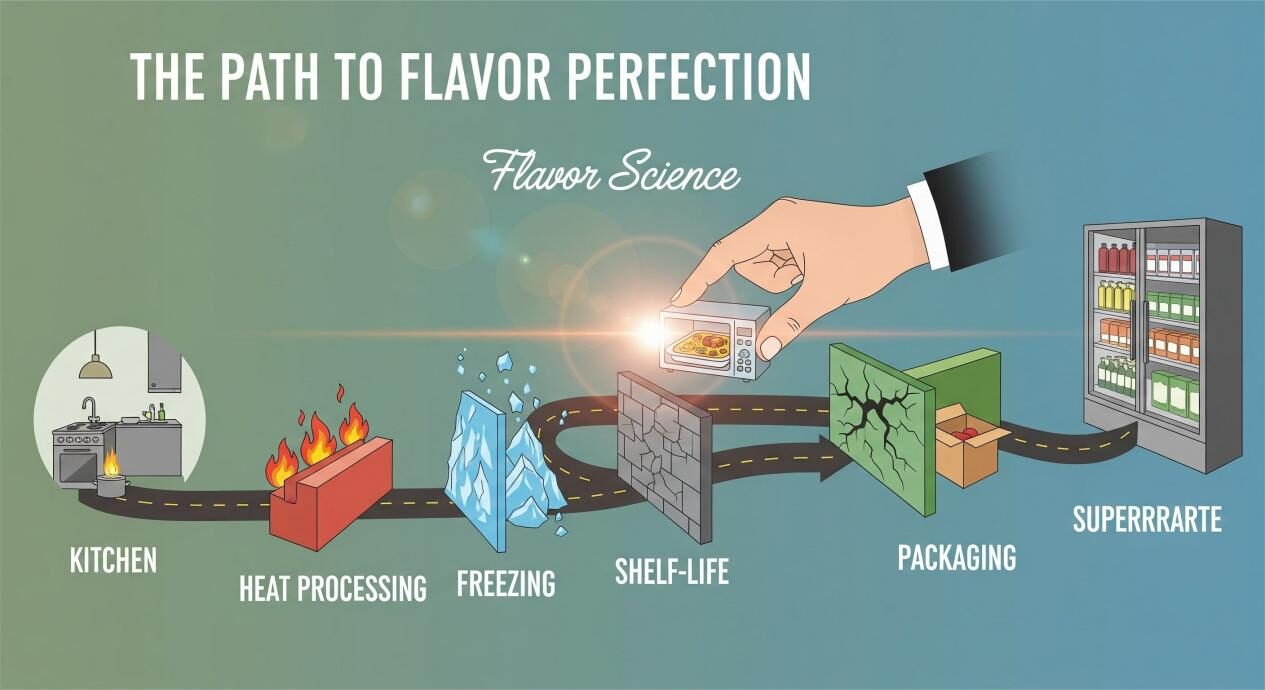

The journey from a brilliant flavor concept in a lab to a fully-formed, delicious ready meal is a battlefield. Flavors must survive a gauntlet of processes that can diminish, alter, or destroy their most delicate notes.

Food manufacturers use various thermal processes to ensure product safety and extend shelf-life. These processes, while necessary, are a primary cause of flavor degradation.

Many convenience meals are frozen for transport and storage. The freezing and thawing cycle can have a detrimental effect on flavor.

A ready meal is rarely a single ingredient; it is a complex system of multiple components.

Even if a flavor survives the manufacturing process, it must remain stable for the product’s entire shelf-life, which can be months or even years.

A 2023 study in the Journal of Food Science highlighted that the combination of thermal processing and long-term storage is a primary cause of flavor degradation in convenience foods, emphasizing the need for robust, scientifically-engineered flavor solutions (Reference 1: J. Food Sci., 2023, “Flavor Degradation and Stabilization in Thermally Processed Foods”).

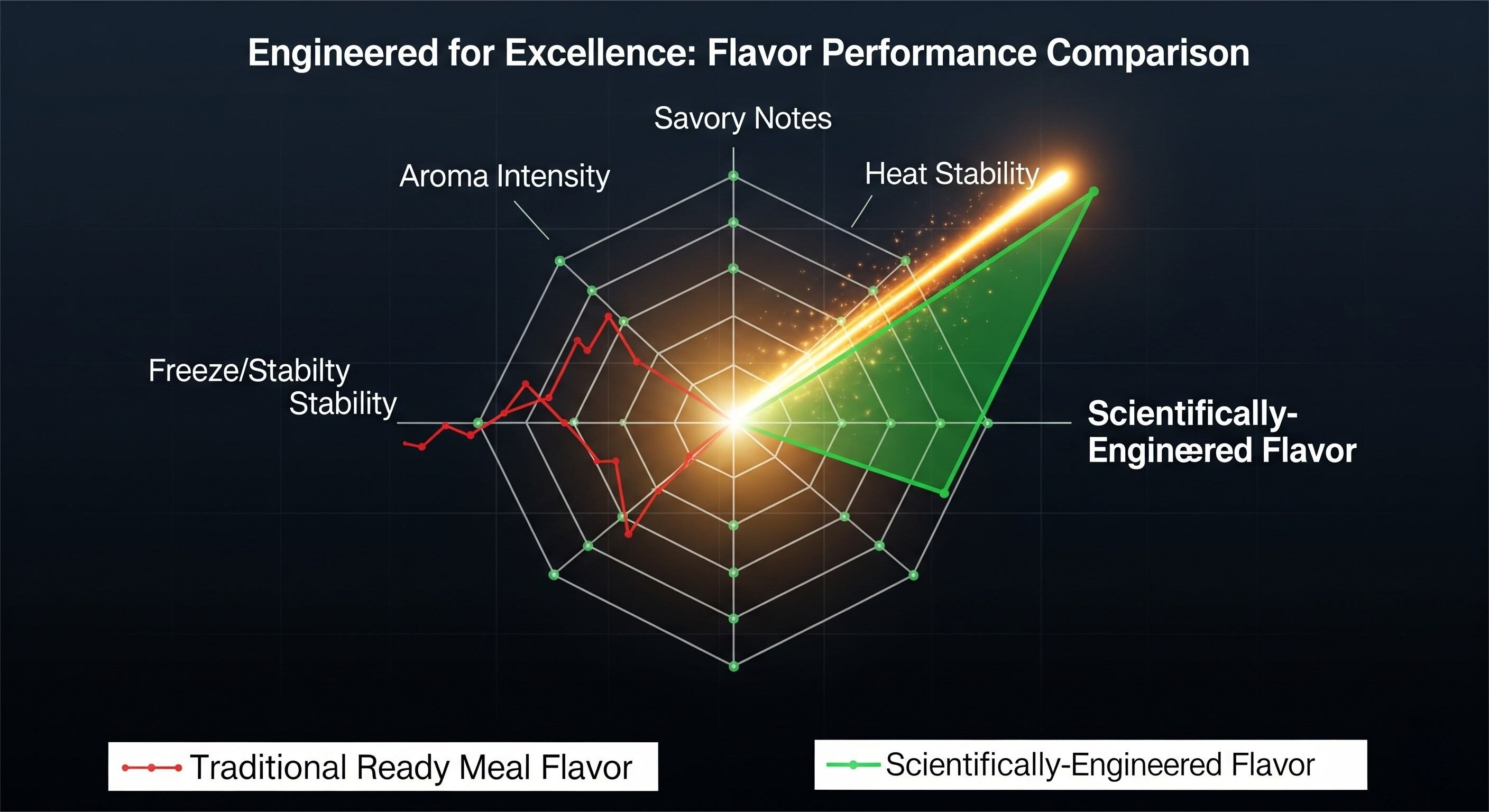

Delivering restaurant-quality taste at scale is a sophisticated challenge that requires a precise, scientific approach. Flavor experts have developed a specialized toolkit of technologies and techniques to ensure flavor success in this demanding category.

Encapsulation is the science of “locking” a flavor inside a protective matrix. It is a powerful tool for protecting volatile flavors from the rigors of production and storage.

Traditional flavors are often a blend of individual aroma chemicals. Reaction flavors are different; they are created by a controlled chemical reaction (the Maillard reaction) that produces deep, savory, and complex flavor notes.

Flavor modulators are specialized compounds that don’t impart a specific flavor but instead enhance the perception of other flavors or mask off-notes.

The demand for clean-label, natural products is a major trend in the ready meal category.

Engineered for Excellence

Delivering restaurant-quality taste in a ready meal is a complex process that requires a close, collaborative partnership between the food manufacturer and the flavor expert.

The process begins with the manufacturer providing a detailed product brief. The flavor house’s team of application scientists and flavorists then conducts a thorough sensory and analytical audit of the base matrix (e.g., the sauce, the vegetable blend). This helps them understand the product’s unique challenges and opportunities.

Based on the audit, the flavor house formulates a custom flavor that is engineered for the specific application (e.g., a retort-stable savory flavor). The flavor is then tested in a pilot-scale trial under conditions that simulate the manufacturer’s actual production process. This is a critical step for de-risking a product launch.

The pilot-scale product is then subjected to rigorous shelf-life and stability testing. This includes accelerated shelf-life testing in an aging oven and real-time monitoring of the product over its entire lifespan. This ensures that the flavor remains consistent and free of off-notes over time.

Once a successful pilot is complete, the flavor house provides support during the final, large-scale production run. They ensure the flavor performs consistently at scale and that quality is maintained across every batch. This provides an invaluable layer of quality assurance that protects the manufacturer’s brand reputation. The Global Food Safety Initiative (GFSI) provides standards for supplier management, which emphasizes the need for this kind of collaborative, end-to-end quality assurance (Reference 3: GFSI, 2024, “Food Safety Management System Requirements”).

A strategic approach to flavor in ready meals is not just a matter of science; it is a critical business decision that provides a powerful competitive advantage.

In the ready meal category, consistency is king. A consumer who buys a product expects it to taste the same every time. A scientifically engineered flavor, developed with the support of a flavor expert, ensures this consistency, which builds invaluable consumer trust and brand loyalty.

A partnership with a flavor expert can drastically reduce the R&D cycle. By preventing common pitfalls and providing expert guidance, a flavor house can help a manufacturer bring a new product to market faster and at a lower cost. This minimizes the risk of costly failed product launches and allows the manufacturer to innovate with confidence. A 2024 report from Bloomberg highlighted that major food companies are leveraging advanced flavor technology to accelerate R&D and gain a competitive edge in the convenience food market (Reference 4: Bloomberg, 2024, “The Future of Food: Accelerating Innovation in Convenience”).

Flavor experts can help manufacturers navigate the complex regulatory landscapes of different countries, ensuring that their flavors are compliant with all food safety and labeling laws. They can also help meet growing consumer demand for clean-label, natural, and allergen-free ingredients.

In a crowded market, a superior flavor profile is a key differentiator. A product that delivers a truly delicious, restaurant-quality taste can command a premium price and dominate its category. It is the single most effective way to stand out from the competition and secure a loyal customer base. The U.S. Food and Drug Administration (FDA) provides clear labeling guidelines for flavors, which a flavor partner can help navigate to ensure a clean, consumer-friendly label (Reference 5: U.S. Food & Drug Administration (FDA), 2024, “Guidance on Flavor Labeling”).

The Promise of Precision

The modern consumer demands both convenience and quality, and the ready meal industry is at the forefront of this revolution. Delivering restaurant-quality taste at scale is a sophisticated challenge, but it is one that can be solved with a strategic, science-based approach to flavor.

A partnership with a flavor expert is not a simple vendor relationship; it is a collaborative alliance that provides the scientific expertise, technical solutions, and strategic guidance needed to navigate the complexities of modern food production. By investing in this partnership, manufacturers can ensure their products are not just convenient, but are also consistently delicious, building a brand that is trusted, loved, and poised for market leadership. The future of the ready meal is not just about speed; it’s about flavor.

Keywords: ready meal flavors, convenience food flavors, meal solution flavors

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Sep 19, 2025

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.