Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 23, 2025

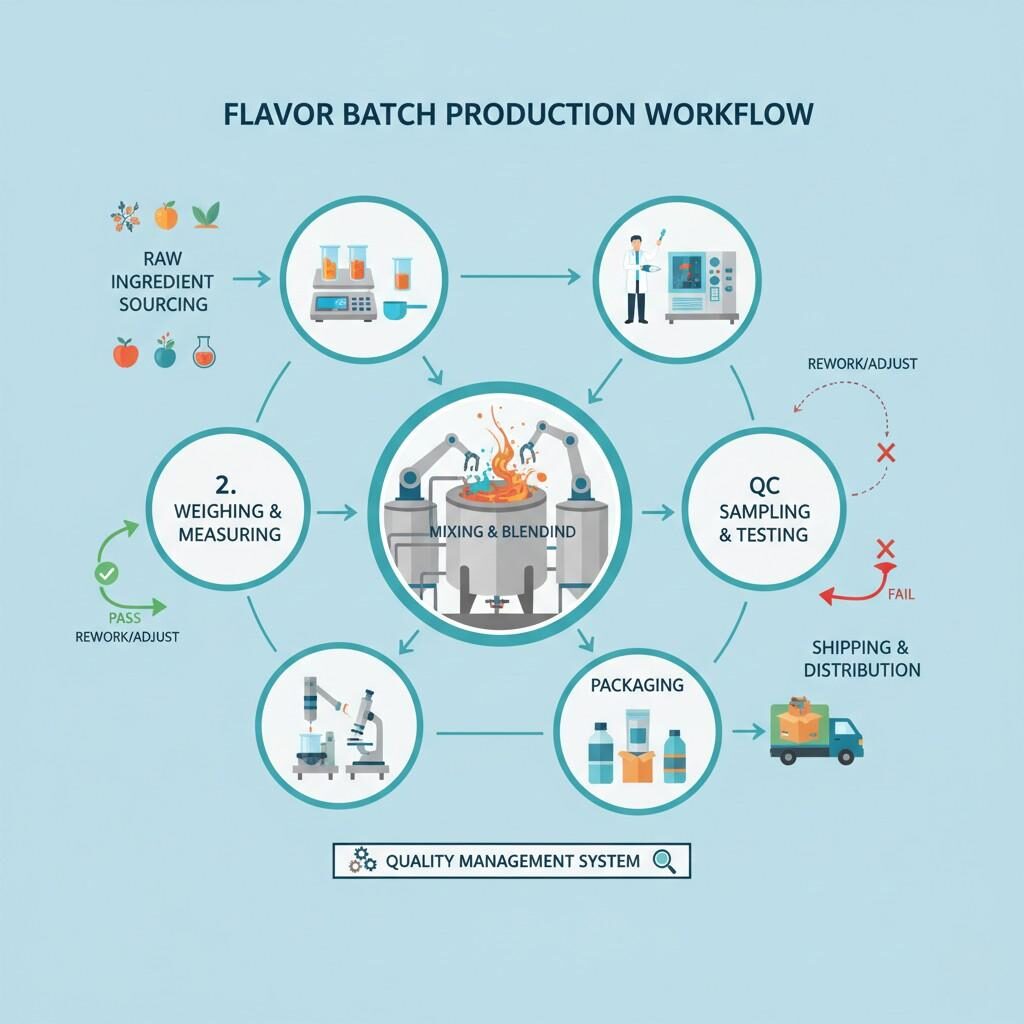

Flavor Production Workflow

In the flavor manufacturing industry, consistency is currency. Whether producing beverage flavors, dairy essences, or bakery aromas, ensuring that every liter of product delivers the same sensory experience is both a scientific challenge and an operational necessity. In large-scale food and beverage production, even slight deviations in ingredient ratios, temperature, or mixing time can lead to perceptible differences in taste and aroma — potentially damaging brand trust and product quality.

As consumer demand grows globally and batch sizes expand from pilot to industrial scale, manufacturers must adopt precision-driven systems for batch control, formulation validation, and sensory quality assurance. This blog explores how to optimize batch production for flavor consistency, covering raw material management, process engineering, sensory validation, and data-driven quality control methods.

Flavor consistency refers to the uniform sensory experience of a product across different production runs. It’s a delicate balance between chemical reproducibility and sensory perception. From a technical standpoint, this involves ensuring identical concentrations of key aroma compounds and controlling chemical interactions that can alter flavor profiles during processing.

Flavors are complex mixtures of volatile organic compounds (VOCs). Factors such as temperature, oxidation, pH, and ingredient matrix can alter the balance of top, middle, and base notes. For instance, citrus oils may lose limonene content due to oxidation, affecting brightness and freshness, while dairy-type flavors may shift due to fat oxidation or Maillard byproducts.

According to the U.S. Food and Drug Administration (FDA), flavor stability and uniformity are critical for labeling compliance and consumer safety standards (source: FDA.gov).

Even with identical chemical composition, sensory differences may occur due to human perception. Therefore, sensory panels and GC–MS (Gas Chromatography–Mass Spectrometry) analysis are often combined to validate reproducibility.

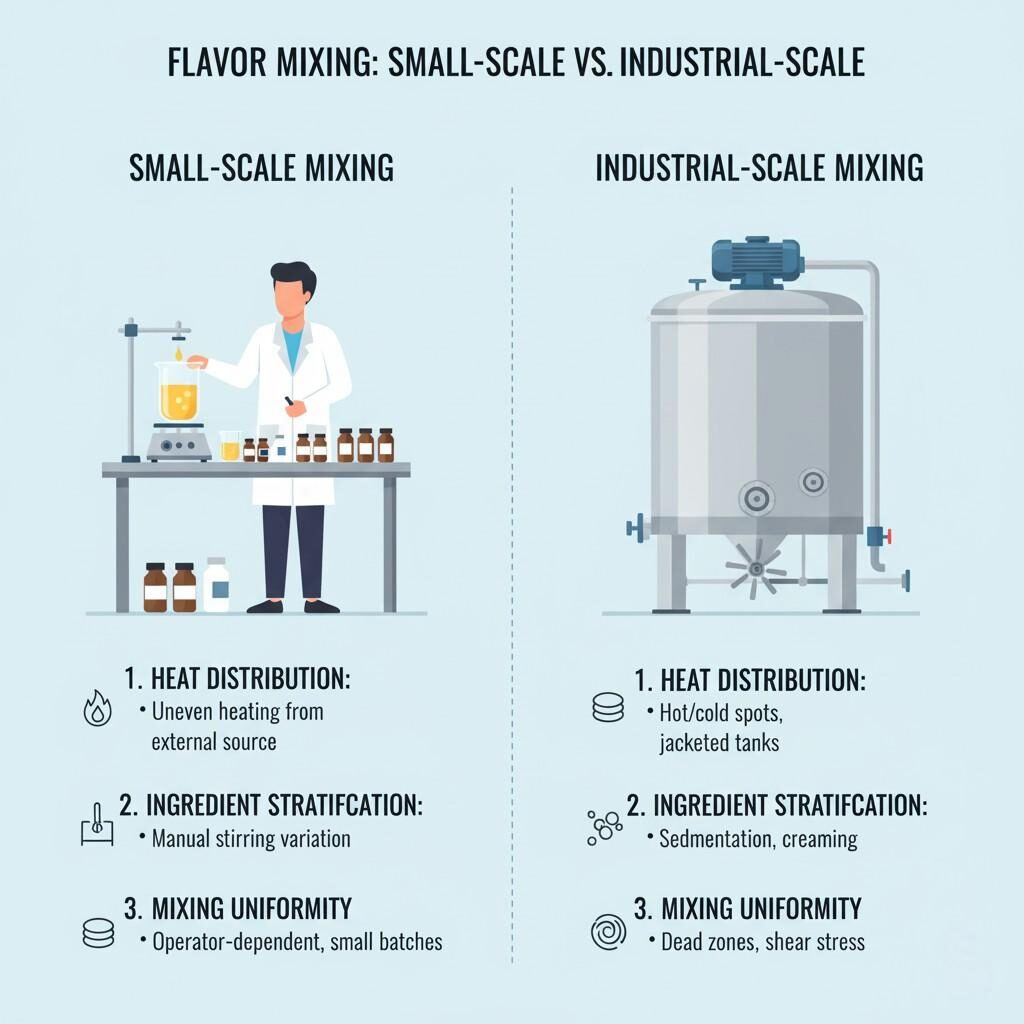

Flavor Mixing Scale Comparison

The journey from bench formulation to full-scale batch production is rarely linear. Parameters like shear rate, mixing speed, and thermal transfer efficiency behave differently in 1000L reactors compared to 1L lab beakers. This can lead to non-linear scaling errors — e.g., uneven dispersion of viscous flavor bases or volatile loss due to prolonged exposure to air.

To mitigate this, pilot-scale validation (typically 10–50L) serves as an intermediary step. Here, process parameters such as mixing time, agitation rate, and order of ingredient addition are optimized before committing to mass production.

Even natural ingredients such as vanilla extract or citrus oil may vary in potency due to crop conditions or extraction efficiency. Implementing supplier standardization and analytical fingerprinting (e.g., GC–MS profile matching) ensures raw materials align with target sensory outcomes.

Humidity, temperature, and even vessel material can influence flavor composition. For example, stainless-steel tanks can minimize odor adsorption, while temperature-controlled mixing rooms reduce volatilization of delicate aroma compounds.

Achieving flavor uniformity at scale requires systematic process control, automation, and data integration. Below are key design considerations:

Automated weighing systems equipped with barcode verification minimize human error in dosing, ensuring every batch adheres to ±0.1% tolerance levels. Some plants also use robotic dispensing for micro-ingredients (e.g., potent aldehydes or esters) that require milligram precision.

Uniform blending depends on the rheological properties of the flavor matrix. For example, oil-based flavors need high-shear homogenization, whereas water-soluble flavors benefit from laminar flow mixing to avoid emulsification instability.

Modern facilities use closed-loop production systems to prevent contamination, evaporation, and odor loss. Nitrogen blanketing and vapor recovery systems are common in high-value aroma production.

Through inline refractometers, viscosity sensors, and density meters, deviations in concentration or solubility can be detected in real time. These are often integrated with SCADA (Supervisory Control and Data Acquisition) systems for automated feedback control.

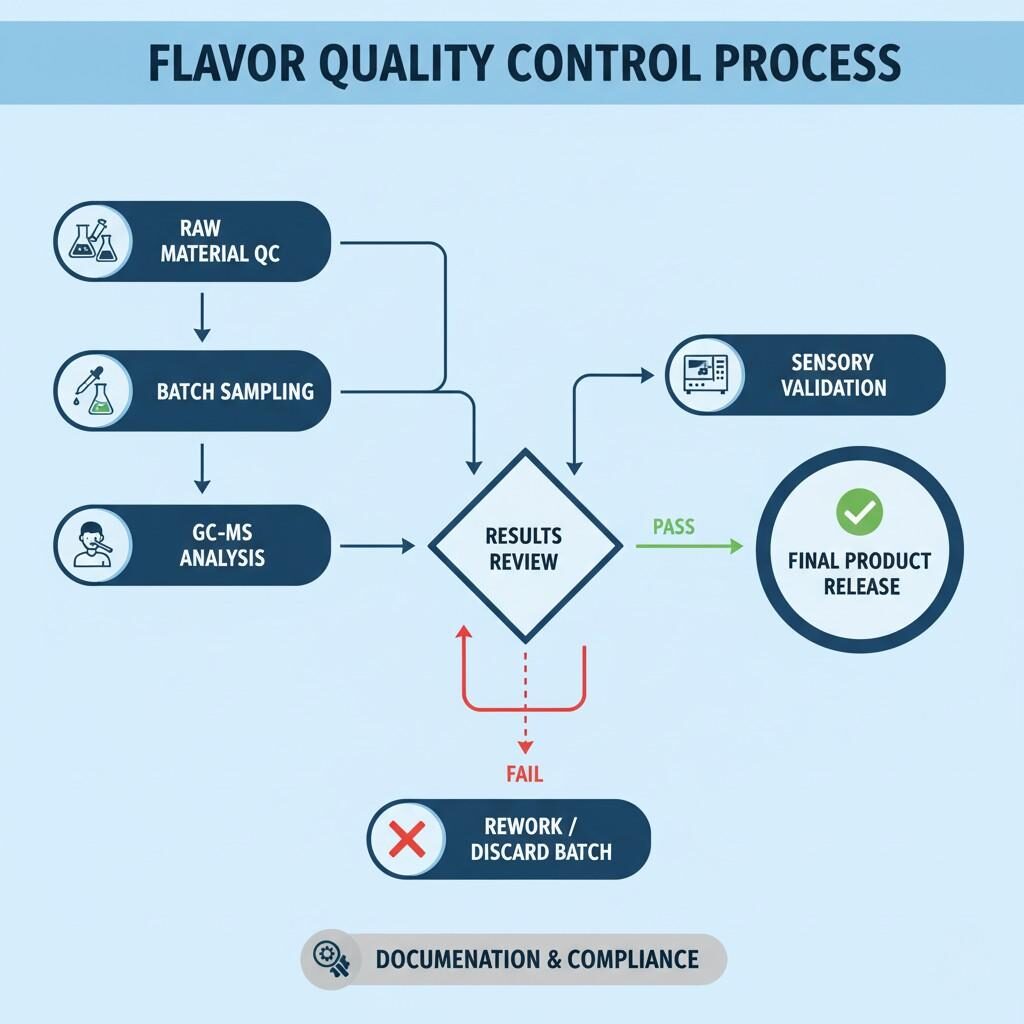

Flavor QC Process Flowchart

Analytical tools such as GC–MS, FTIR (Fourier-Transform Infrared Spectroscopy), and HPLC are the backbone of flavor verification. These allow detection of micro-level deviations in key aroma compounds, ensuring consistency between production lots.

The European Food Safety Authority (EFSA) emphasizes analytical reproducibility and traceability as a key part of food ingredient manufacturing regulations (source: EFSA.europa.eu).

A trained sensory panel provides the final human validation. By performing triangle tests and descriptive analysis, evaluators ensure that no perceptible difference exists between production batches.

Flavor degradation under storage conditions can be tested through accelerated stability protocols, where temperature and light exposure simulate months of shelf life. This helps manufacturers anticipate flavor drift and adjust formulation buffers accordingly.

Consistency improvement is no longer just about hardware — it’s about data intelligence. Advanced digital tools help manufacturers correlate batch parameters with sensory outcomes.

Modern flavor facilities are integrating MES (Manufacturing Execution Systems) that record every variable — from ingredient lot number to mixing torque. This data enables root cause analysis in case of off-flavors and enhances reproducibility.

AI-driven analytics can forecast the sensory outcome of a batch before it is produced. For instance, machine learning algorithms can compare chemical profiles to sensory databases, helping technicians adjust formulations proactively.

According to McKinsey & Company’s 2023 Food Manufacturing Report, digital traceability and predictive analytics reduce batch variation by up to 30%, improving yield and reducing waste (source: McKinsey.com).

Even with advanced automation, operator training remains critical. Flavor technicians must understand not only the machinery but also the chemistry of aroma interactions. Regular calibration of sensory skills and procedural adherence ensures the system’s human component remains as consistent as its mechanical one.

The Institute of Food Technologists (IFT) underscores the importance of standard operating procedures (SOPs) and continuous sensory training in flavor production environments (source: IFT.org).

Emerging technologies such as inline aroma sensors, AI-based aroma fingerprinting, and blockchain-based ingredient traceability will further reduce flavor variation across global production networks. Manufacturers adopting these innovations will gain both regulatory advantage and market credibility.

Intelligent Flavor Production Future

Flavor consistency in batch production is not a one-time achievement — it’s a continuous pursuit that blends chemistry, process engineering, and data science. From sourcing stable raw materials to applying advanced analytical verification, every stage must align with the goal of delivering a uniform sensory experience.

For food and beverage brands, this consistency defines consumer trust and brand identity. Partnering with a professional flavor manufacturer experienced in batch control, digital traceability, and sensory analysis can ensure your product always delivers the same excellence — no matter the scale.

At CUIGUAI Flavor, we specialize in precision-engineered food and beverage flavor solutions, ensuring exceptional consistency and compliance across every production scale.

Contact our technical team today for a free formulation consultation or to request flavor samples for your next product line.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.cn】

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.