Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 24, 2025

Flavor R&D Lab Collaboration

In the fast-paced food and beverage market, speed-to-market has become a decisive competitive advantage. Launch windows are shorter, consumer trends evolve faster, and innovation cycles that once took years now must be compressed into months — or even weeks. Yet, while speed is critical, product quality, sensory impact, and regulatory compliance cannot be compromised.

This is where expert flavor partners play a pivotal role. Partnering with a professional flavor manufacturer allows food and beverage brands to shorten their development cycle without sacrificing precision, taste consistency, or safety. By leveraging advanced flavor technologies, sensory analytics, and integrated R&D processes, brands can move from concept to launch more efficiently than ever before.

This article explores the strategies, tools, and collaborative frameworks that can help brands accelerate product development through professional flavor partnerships — while maintaining the highest standards of taste and compliance.

The traditional product development process — from concept ideation to market launch — often involves lengthy iterations of formulation, testing, and validation. Each phase can extend timelines and inflate costs.

According to a 2023 report by McKinsey & Company, the average food product development cycle ranges between 12 to 24 months, depending on complexity and regulatory testing. However, in fast-moving categories such as ready-to-drink (RTD) beverages, plant-based foods, and functional nutrition products, consumer trends can shift in less than six months (source: McKinsey.com).

In such conditions, agility is as important as innovation. Companies that can rapidly test, refine, and validate new products gain not only market share but also early brand recognition.

Common barriers to fast product launch include:

A skilled flavor partner can address these issues by integrating flavor chemistry, analytical science, and regulatory insight into your development process.

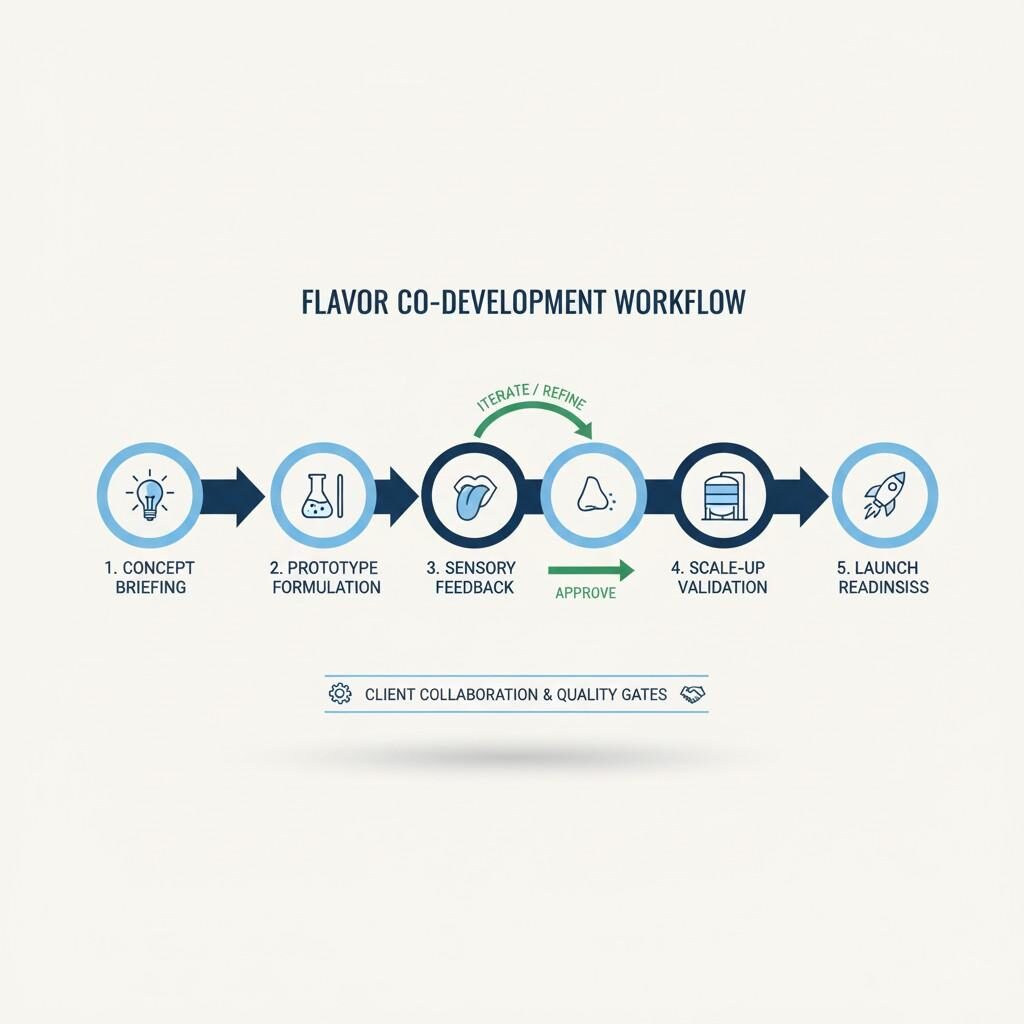

Flavor Co-Development Workflow

An expert flavor house brings technical capability, infrastructure, and experience that significantly shorten product cycles.

Professional flavor partners maintain extensive aroma libraries and compound databases that allow quick selection and combination of existing profiles. Instead of formulating from scratch, R&D teams can select from pre-validated base flavors, drastically cutting formulation time.

Advanced facilities employ tools like:

Working with a flavor partner transforms the relationship from supplier to co-developer. This collaboration integrates:

Such integration ensures each prototype aligns with both sensory and functional expectations before large-scale production.

Experienced flavor manufacturers maintain libraries of thousands of formulations validated for stability, solubility, and heat resistance. This “shortcut” resource helps clients launch new variants or reformulate existing ones quickly — for example, adapting a fruit flavor for both carbonated and non-carbonated systems.

Reducing the development cycle isn’t simply about working faster — it’s about designing smarter workflows with reduced redundancies and better data sharing. Here’s how an expert flavor partner optimizes each stage.

Flavor innovation begins with translating consumer trends into sensory direction. For instance, emerging interests in functional beverages, plant-based proteins, and low-sugar alternatives demand novel flavor masking and enhancement techniques.

A professional flavor house often supports brands with trend analysis, providing insights derived from global market monitoring and sensory databases (e.g., Mintel, Innova, or FMCG trend platforms).

According to Innova Market Insights, 74% of consumers now associate “natural flavor” with product quality and safety, influencing formulation direction (source: Innova Market Insights, 2024 Global Trends Report).

Using advanced software and digital sensory modeling, flavorists can simulate flavor volatility, solubility, and interaction with key ingredients (proteins, acids, fats). This predictive approach minimizes physical trials, saving both time and materials.

Examples of key tools:

Before scale-up, pilot testing ensures that the flavor behaves consistently under industrial conditions. This includes:

Flavor partners can perform rapid sensory feedback cycles, often completing multiple iterations in days rather than weeks.

Scaling up to commercial batches often introduces variability due to mixing, thermal, or ingredient supply differences. A professional flavor manufacturer ensures:

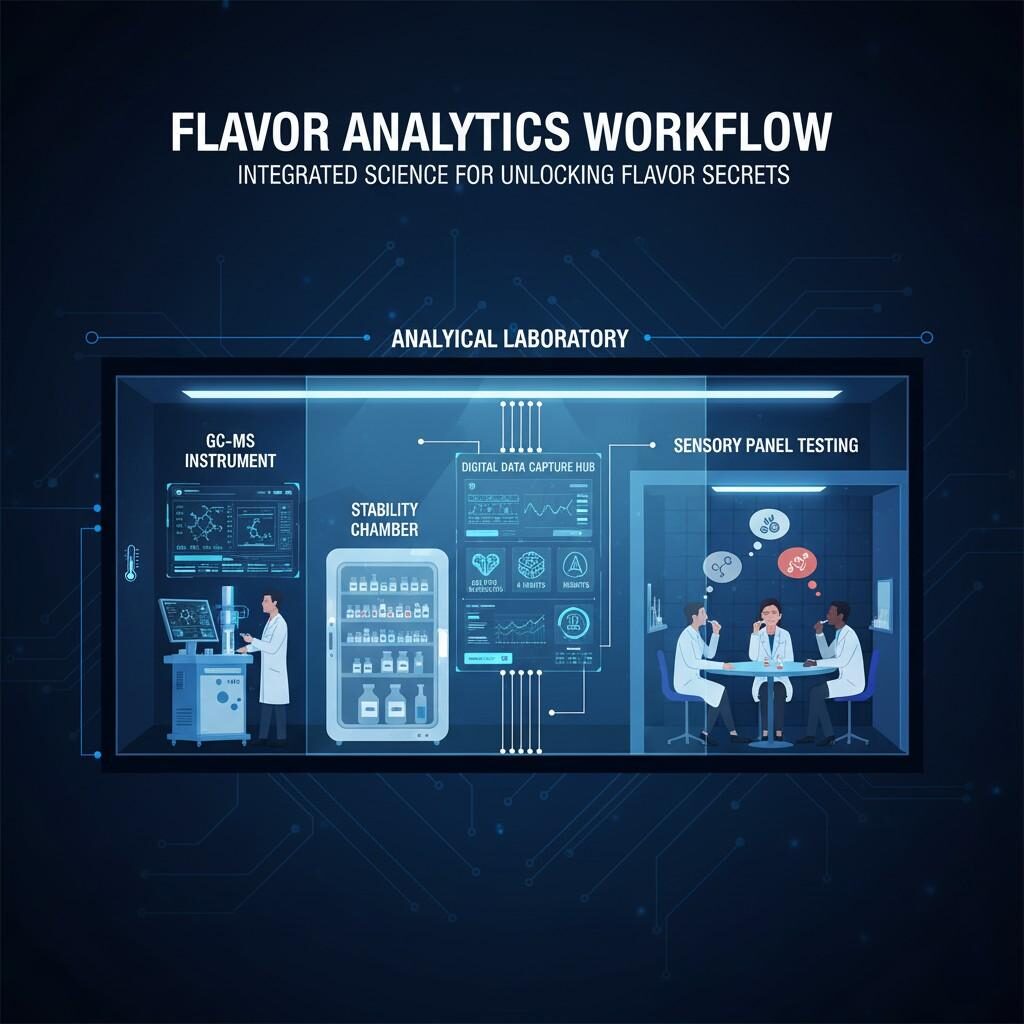

Flavor Analytics Workflow

Technology underpins every aspect of modern flavor development. Leading manufacturers deploy a combination of analytical chemistry, digital formulation platforms, and automation to minimize cycle times.

Digital formulation management allows real-time sharing of flavor data — composition, solubility, volatility, sensory profile — across R&D teams and clients. This facilitates parallel development and rapid feedback integration.

Machine learning models trained on sensory databases can predict how chemical compositions will perform in different applications. This enables data-driven prototyping, significantly reducing manual trial-and-error.

For instance, an AI-based model may predict that adding ethyl butyrate to a tropical fruit flavor increases perceived sweetness by 12%, aligning with desired taste profiles faster.

Flavor labs equipped with robotic dispensers can prepare multiple flavor variants simultaneously — each with microgram precision. What once took days can now be achieved in hours, ensuring consistent, accurate samples for client evaluation.

Automated compliance systems generate ingredient documentation and labeling reports aligned with global standards such as Codex Alimentarius and the EU Flavouring Regulation (1334/2008) (source: European Commission).

Many successful brands work hand-in-hand with flavor partners through flavor creation workshops — on-site or virtual — that compress weeks of correspondence into a few focused days. Immediate sensory feedback and reformulation cycles accelerate alignment and decision-making.

Leading flavor manufacturers offer application laboratories that mirror real production conditions (e.g., beverage carbonation, thermal processing, baking). This ensures rapid transition from bench to plant.

Sensory panels trained in flavor intensity scaling can evaluate up to 50 prototypes per day, providing structured data for quick refinement. This approach enables brands to validate consumer fit and stability simultaneously.

A mid-sized beverage company aimed to launch a new vitamin-enriched sparkling drink within six months — less than half their typical development time.

Working with an expert flavor partner, they:

The product successfully launched within five months, maintaining both sensory integrity and labeling compliance across three markets.

Speed should never compromise product safety or consistency. A professional flavor partner ensures:

The U.S. Food and Drug Administration (FDA) requires that all flavoring substances comply with recognized safety standards under 21 CFR §172.515 for food additives (source: FDA.gov).

Accelerated development success is measurable through KPIs such as:

With digital collaboration and expert flavor support, these metrics can improve by 25–50%, leading to faster launches and reduced R&D costs.

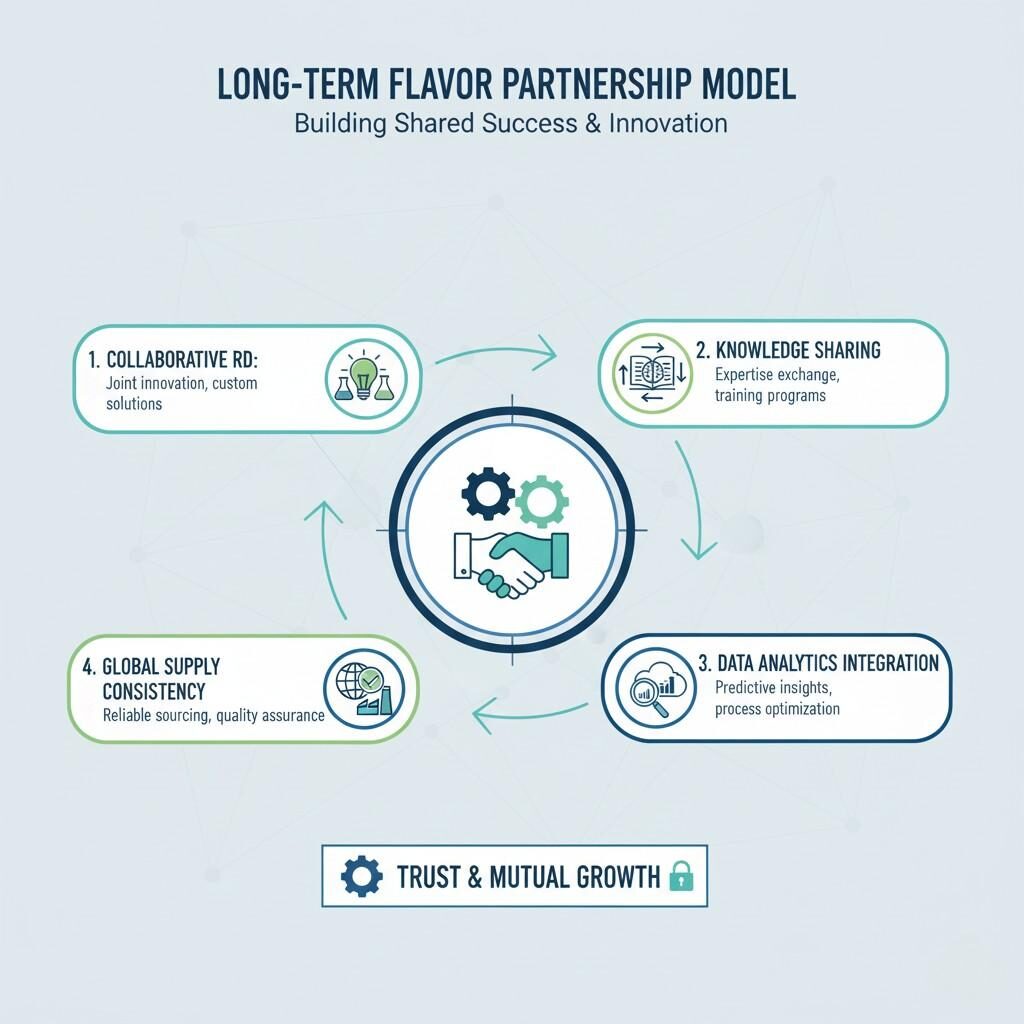

Long-Term Flavor Partnership

Choosing the right flavor partner is not just a tactical decision; it’s a strategic investment in future innovation. Ongoing collaboration brings continuous advantages:

In today’s competitive food and beverage landscape, speed without precision is risky — but speed with expertise is transformative. Reducing development cycles requires a balance of scientific rigor, cross-functional communication, and reliable partnerships.

By collaborating with an expert flavor manufacturer, brands gain immediate access to analytical tools, experienced flavorists, and established compliance frameworks — enabling faster launches without compromise on taste, safety, or quality.

Whether you’re reformulating an existing product or developing an entirely new line, a skilled flavor partner can help turn creative concepts into market-ready realities faster than ever before.

At [Your Company Name], we specialize in end-to-end flavor solutions designed to accelerate innovation cycles while ensuring regulatory compliance and exceptional taste performance.

Partner with our expert team for rapid flavor development, technical consultation, or free flavor sample requests to support your next product launch.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.cn】

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.