Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 21, 2026

Pouring Fresh Creamy Herb Dressing

In the competitive landscape of the global condiment market, the “shelf-stable” designation is both a logistical necessity and a significant technical hurdle. For manufacturers of sauces, dressings, and marinades, the ultimate goal is to deliver a product that retains its intended sensory profile—vibrancy, aroma, and mouthfeel—from the moment it leaves the production line until it is consumed, often twelve to eighteen months later.

However, shelf stability is not a passive state. It is the result of an aggressive preservation strategy that often includes acidification, reduction of water activity, and intense thermal processing (such as pasteurization or retort). Each of these interventions, while necessary for microbial safety, acts as a stressor on the delicate chemical structure of flavors.

As a professional manufacturer of food and beverage flavorings, we recognize that maintaining flavor integrity requires a multidisciplinary approach. It involves the chemistry of volatile organic compounds, the physics of emulsion science, and the biology of human perception. This article provides a deep technical analysis of how to engineer sauces and dressings that stand the test of time.

To achieve shelf stability without constant refrigeration, formulators must manipulate the two primary pillars of food preservation: pH and Water Activity (aw). While these parameters inhibit the growth of pathogens like Clostridium botulinum, they fundamentally alter the way flavor molecules behave.

Most shelf-stable dressings are “acidified foods,” meaning they have a natural or added pH of 4.6 or below. The use of organic acids—most commonly acetic (vinegar), citric (lemon/lime), or lactic acid—is essential for safety but creates a “hostile” environment for many flavor aromatics.

Water activity represents the energy status of water in a system. In shelf-stable sauces like BBQ or Teriyaki, high concentrations of sugar and salt are used to bind water, bringing the aw down to 0.85 or lower.

The aw level dictates the “volatility” of flavor compounds. In a high-water-activity environment, flavor molecules move freely. In low aw systems, the viscosity usually increases, and the flavor molecules are “bound” more tightly to the matrix. This leads to a slower “flavor bloom” in the mouth. To counteract this, we utilize flavor carriers with low surface tension to help the aromatics “escape” the sugar-dense matrix during consumption.

According to the U.S. Food and Drug Administration (FDA), the control of water activity is a primary critical control point (CCP) in the manufacturing of shelf-stable condiments to ensure that the product remains “commercially sterile.” (Citation 1).

Creamy dressings (like Ranch, Caesar, or Blue Cheese) are typically Oil-in-Water (O/W) emulsions. The stability of this emulsion is the single most important factor in how flavor is delivered to the palate.

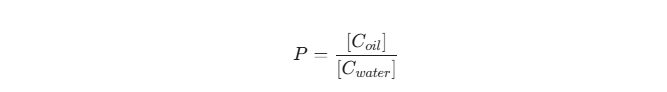

Flavor molecules are rarely equally soluble in oil and water. They “partition” themselves based on their chemical affinity. The Partition Coefficient (P) is a critical metric for formulators:

In a creamy dressing, the majority of savory and “green” notes are lipophilic (high P). They reside within the oil droplets. If the oil droplets are too large or the emulsion is unstable, the flavor release will be inconsistent.

Syneresis, or the “weeping” of water from the sauce matrix, is a common shelf-life failure. When water separates, it carries with it the water-soluble flavor fractions and acids. This results in a product that tastes “sharp” and “thin” at the top of the bottle and “bland” or “oily” at the bottom. We solve this by using synergistic blends of hydrocolloids (such as Xanthan gum and Modified Food Starch) that create a robust network, preventing the migration of flavor-carrying fluids.

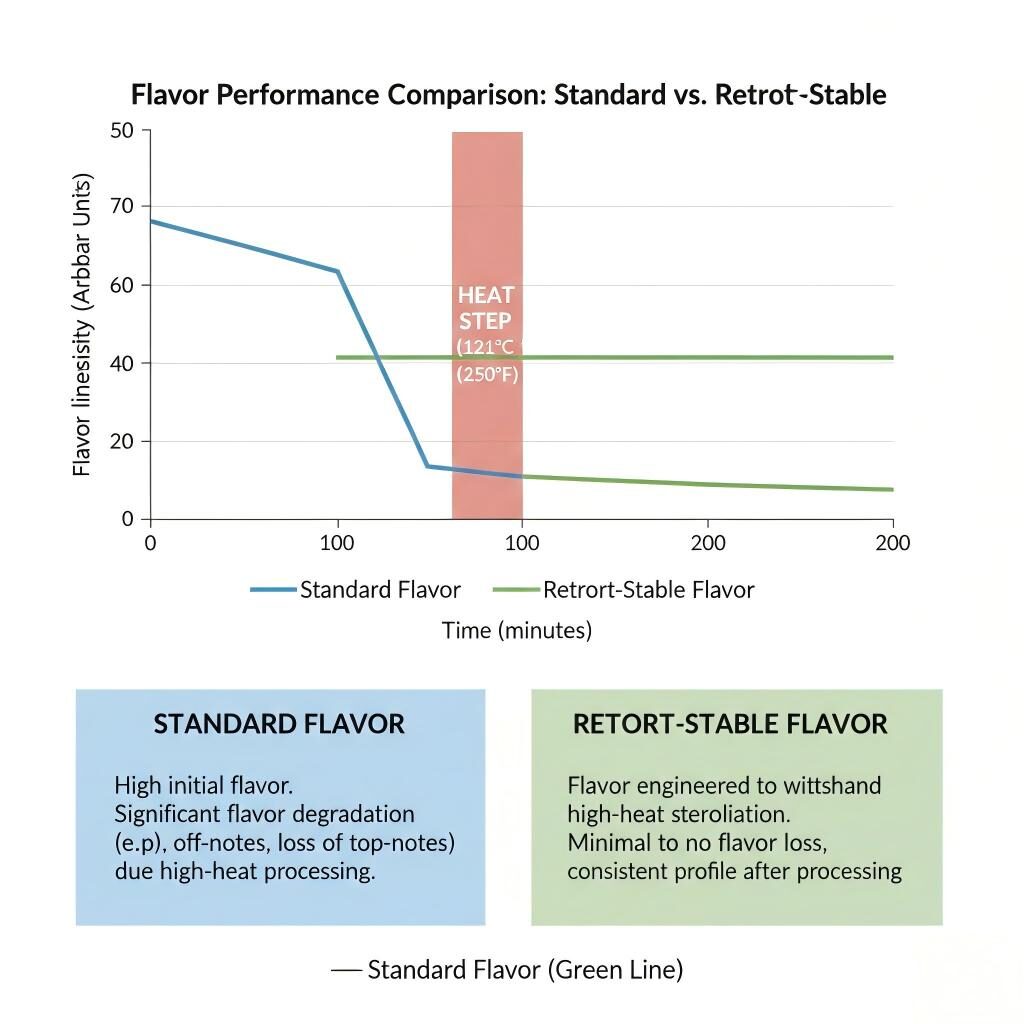

To ensure a shelf life of 12+ months at room temperature, most sauces must undergo a thermal kill step. This can range from Hot-Fill-Hold (8 ℃ – 95 ℃) to full Retort (121 ℃).

Retorting is the most aggressive form of processing. The high heat can trigger the Maillard reaction between amino acids and reducing sugars in the sauce. While this is great for a “Roasted Garlic” sauce, it can be disastrous for a “Fresh Basil” pesto sauce, turning the bright herbal notes into something that tastes like hay or cooked vegetables.

Onion and garlic are staples in the sauce world. Their characteristic “pungency” comes from volatile sulfur compounds like allicin and diallyl disulfide. These molecules are extremely unstable. Under heat, they degrade into trisulfides and tetrasulfides, which have a “canned” or “eggy” aroma.

As noted in the Journal of Agricultural and Food Chemistry, the degradation of organosulfur compounds in processed vegetables is a primary cause of sensory deviation in shelf-stable products. (Citation 2). Our R&D team counters this by using stabilized “Allium” extracts that are standardized for heat resistance.

Retort-Stable vs. Standard Flavor Performance

Once the sauce is bottled and placed on a shelf, the clock begins to tick. The two greatest threats during storage are Oxidation and Packaging Interaction.

Oil-based dressings are highly susceptible to oxidation. When the unsaturated fats in soybean or canola oil react with the small amount of oxygen trapped in the bottle’s headspace, they produce aldehydes and ketones that taste “painty” or “fishy.”

If your sauce is packaged in plastic (PET, PE, or PP), you may encounter “flavor scalping.” This occurs when the plastic packaging acts as a sponge, absorbing the non-polar flavor molecules (like limonene from citrus or menthol from mint) out of the sauce.

The modern consumer demands a “Clean Label,” which means formulators must often remove traditional preservatives like Potassium Sorbate or Sodium Benzoate. This places the entire burden of stability on the flavor and the processing.

Many natural flavor components possess inherent antimicrobial properties. For example:

By strategically building a flavor profile that utilizes these natural extracts, we can create a “dual-purpose” ingredient that provides both the desired taste profile and a secondary layer of microbial protection.

Replacing modified starches with “Native” starches or gums (like Xanthan or Locust Bean Gum) changes the way flavor is released. Native starches tend to have a “pasty” mouthfeel that can coat the tongue and mute the flavor perception.

According to research from Cornell University, the interaction between starch granules and flavor volatiles is a key factor in the sensory quality of thickened foods. (Citation 3). We adjust our flavor concentrations to account for the “masking” effect of these natural thickeners.

Clean Label Ingredient Comparison

Flavor integrity isn’t just about what’s in the bottle; it’s about how the consumer perceives it. This involves the concept of Flavor Congruency.

If a sauce is intended to be “Spicy Sriracha,” the brain expects a certain level of acidity and sweetness. If the acidity is too high (due to preservation needs), but the “heat” profile of the chili flavor doesn’t match that acidity, the brain perceives the flavor as “off” or “unbalanced,” even if the chemistry is stable.

We use Sensory Mapping to ensure that all five tastes (Sweet, Sour, Salty, Bitter, Umami) are in harmony with the aromatic top notes. For a shelf-stable product, this balance must be engineered for the “mid-life” of the product—not just the first week.

How do we prove a flavor will last 12 months without waiting a year? We use Accelerated Shelf-Life Testing (ASLT).

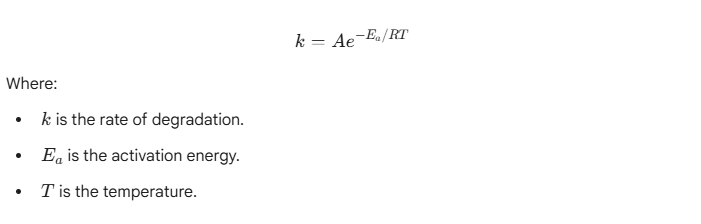

Chemical reactions (like flavor degradation) generally double in speed for every 10 ℃ increase in temperature. By storing samples at 37 ℃ or 45 ℃, we can simulate 12 months of room-temperature storage in approximately 6 to 8 weeks.

We use Gas Chromatography-Mass Spectrometry (GC-MS) to create a “molecular fingerprint” of the sauce at Day 0. During ASLT, we re-run the fingerprint at regular intervals. If a specific peak (representing a key flavor molecule) drops by more than 20%, we know we have a stability issue that needs to be addressed through reformulation or encapsulation.

The Institute of Food Technologists (IFT) highlights that the combination of analytical chemistry and trained sensory panels is the only reliable way to validate the shelf life of complex food matrices like sauces and dressings. (Citation 4).

For the professional formulator, here is a technical checklist to ensure your shelf-stable sauce succeeds:

The creation of a shelf-stable sauce or dressing is a testament to modern food engineering. It requires a delicate dance between the harsh requirements of safety and the ephemeral nature of flavor. By understanding the kinetics of flavor molecules—how they partition, how they react to heat, and how they interact with their environment—we can create products that transcend the limitations of the shelf.

In the world of professional flavorings, we don’t just provide a taste; we provide a technical solution that ensures your brand’s promise is kept, one bottle at a time.

Culinary Science Sauce Analysis

Are you struggling with flavor “fade” in your latest sauce formulation, or are you looking to remove preservatives without sacrificing taste? Our technical R&D team is ready to collaborate.

Would you like to schedule a technical exchange with our flavor chemists to discuss your specific matrix, or would you like to request a free “Stability-Plus” sample kit for your next pilot run?

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.