Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 25, 2025

Seed to Shelf: Pure Flavor Journey

In today’s competitive food and beverage landscape, flavor is no longer just an additive — it is the defining factor that determines consumer preference, brand identity, and product success. From ready-to-drink beverages and dairy products to bakery and plant-based innovations, the demand for distinctive, safe, and high-quality food-grade flavors continues to surge worldwide.

Yet, as consumer expectations evolve, so do the challenges of sourcing flavors efficiently. Long lead times, fragmented suppliers, and complex global regulations can slow down product development and erode profitability. To stay ahead, companies must rethink how they procure flavors strategically — integrating technical evaluation, supplier partnerships, and digital transformation.

This comprehensive guide explores how to streamline your food-grade flavor sourcing process — from supplier selection and regulatory compliance to digital procurement platforms and sustainability. Whether you are a product developer, purchasing manager, or flavor R&D professional, this article will help you master the art and science of efficient flavor procurement.

Flavors serve three essential functions in food and beverage manufacturing:

According to the International Organization of the Flavor Industry (IOFI), the global flavor market exceeded US$18 billion in 2024, driven by innovations in natural, clean-label, and functional flavor categories. Efficient procurement strategies directly influence speed-to-market and cost competitiveness.

Citation 1: International Organization of the Flavor Industry (IOFI). (2024). Global Market Overview: Food Flavor Trends and Compliance Framework. Retrieved from https://www.iofi.org

Many food manufacturers encounter recurring pain points in their sourcing process:

Addressing these challenges requires a structured procurement strategy that integrates technical expertise, supplier collaboration, and digital solutions.

When sourcing flavors, compliance is non-negotiable. A reliable supplier must adhere to recognized food safety management systems and provide full transparency regarding raw materials and production processes.

Key certifications and standards include:

Citation 2: U.S. Food and Drug Administration (FDA). (2023). Generally Recognized as Safe (GRAS) Substances Overview. Retrieved from https://www.fda.gov/food

A technically competent supplier will not only meet these certifications but also offer full documentation packages, including:

An efficient procurement process prioritizes suppliers who combine scientific expertise with flexible manufacturing capabilities. Key features to evaluate include:

Selecting such partners can reduce development cycles by 30–40%, accelerating your time-to-market.

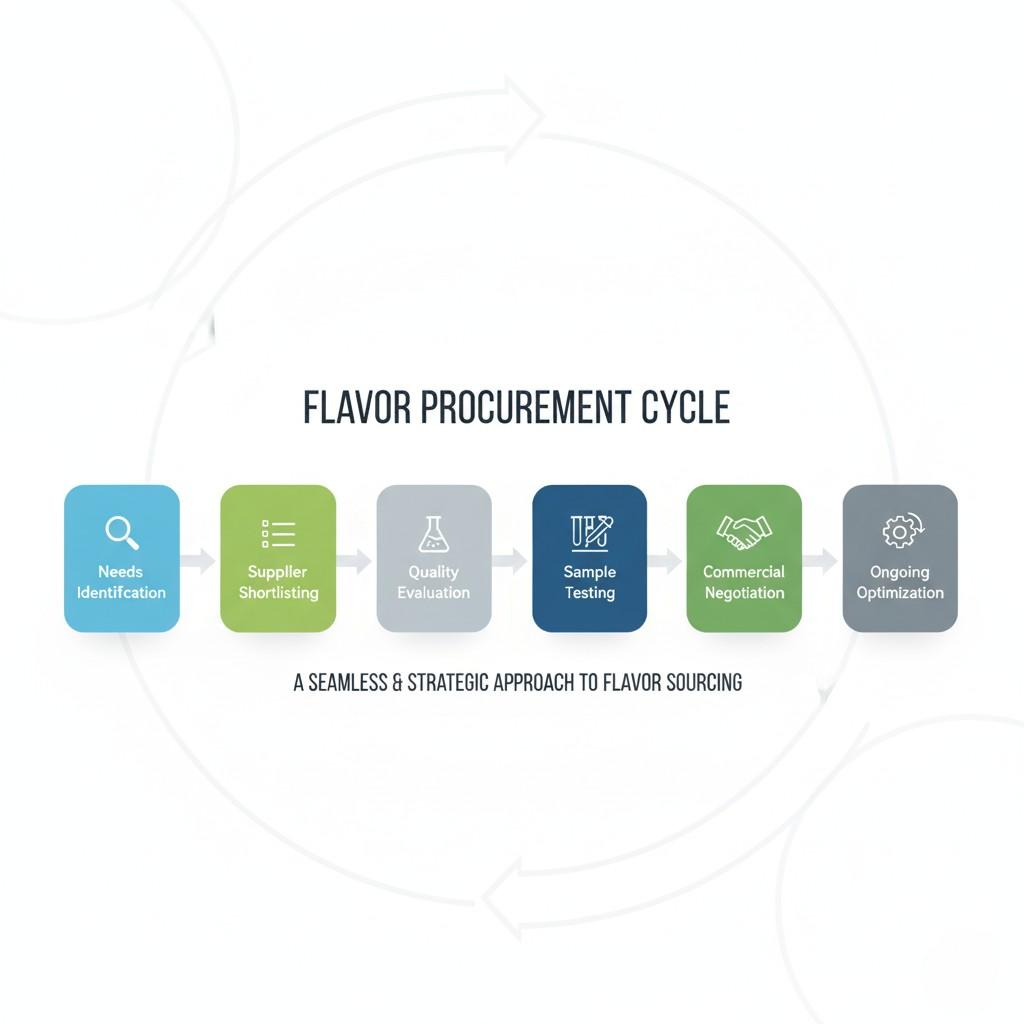

Flavor Procurement Cycle

Begin by clearly defining your application requirements:

Collaborate closely with your flavor supplier’s technical team to establish analytical and sensory benchmarks. This ensures that your flavor not only meets the brief but also remains stable through processing and storage.

When comparing suppliers, look beyond price. Focus on:

A structured supplier scorecard can quantify these parameters for objective comparison. Many leading manufacturers integrate supplier data into digital platforms for real-time evaluation.

Every new flavor must undergo rigorous sensory and analytical validation:

According to the Institute of Food Technologists (IFT), 72% of failed product launches stem from sensory misalignment — not from ingredient cost or processing issues. Structured sensory validation thus becomes a cornerstone of efficient procurement.

Citation 3: Institute of Food Technologists (IFT). (2022). Sensory Science and Product Success in Food Manufacturing. Retrieved from https://www.ift.org

Once quality approval is secured, procurement teams must negotiate:

Integrating logistics and demand forecasting tools ensures inventory stability and minimizes waste.

In practice, partnering with a manufacturer that offers both technical customization and supply reliability, such as CUIGUAI Flavoring, can dramatically improve cost-efficiency and operational flow.

Digital transformation is reshaping ingredient sourcing. Cloud-based systems allow buyers to manage RFQs, evaluate suppliers, and track deliveries with transparency and speed.

E-procurement platforms also enable:

According to McKinsey & Company, companies adopting digital sourcing strategies have reported up to 20% faster procurement cycles and 10–15% cost savings across their supply chains.

Citation 4: McKinsey & Company. (2023). Digital Procurement: How Technology Is Transforming Sourcing Operations in Food Manufacturing. Retrieved from https://www.mckinsey.com

Flavor procurement teams increasingly rely on AI-assisted analytics to:

This data-driven approach reduces human bias and improves forecasting accuracy, ensuring that flavor sourcing becomes a strategic differentiator rather than a reactive task.

Flavor Procurement Analytics Dashboard

Consumers increasingly demand products made with natural and ethically sourced ingredients. Food manufacturers are therefore seeking suppliers that:

Sustainable flavor sourcing is no longer optional — it is central to brand credibility and global compliance (e.g., EU Green Deal and U.S. FDA modernization acts).

Forward-thinking flavor manufacturers are integrating circular economy principles:

At CUIGUAI Flavoring, sustainability is embedded into product design and production — from raw material selection to energy-efficient processes — helping clients meet both environmental and commercial goals.

The best procurement systems are built on relationships, not transactions. Long-term collaboration with flavor manufacturers fosters:

Suppliers who act as strategic partners invest in your growth — offering R&D alignment, trend forecasting, and joint problem-solving.

Effective partnerships thrive on transparency and knowledge exchange. Through technical workshops, sensory calibration, and joint audits, both sides can enhance efficiency and reduce risk.

Partners in Flavor Innovation

Efficient food-grade flavor sourcing is not merely about cutting costs — it’s about unlocking agility, reliability, and innovation across your value chain. By integrating digital procurement tools, aligning with certified suppliers, and prioritizing sustainability, manufacturers can ensure every flavor they use contributes to brand consistency and consumer trust.

At CUIGUAI Flavoring, we combine scientific expertise, certified production, and responsive support to help global food brands streamline their sourcing. From customized natural flavors to regulatory documentation and sample delivery, we are your trusted partner for smart, efficient, and safe flavor procurement.

Looking to simplify your food-grade flavor sourcing and accelerate product development?

📩 Contact CUIGUAI Flavoring for a technical consultation or free flavor sample request.

Let’s co-create flavors that are not only delicious — but efficient, compliant, and sustainable.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.cn】

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.