Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 17, 2025

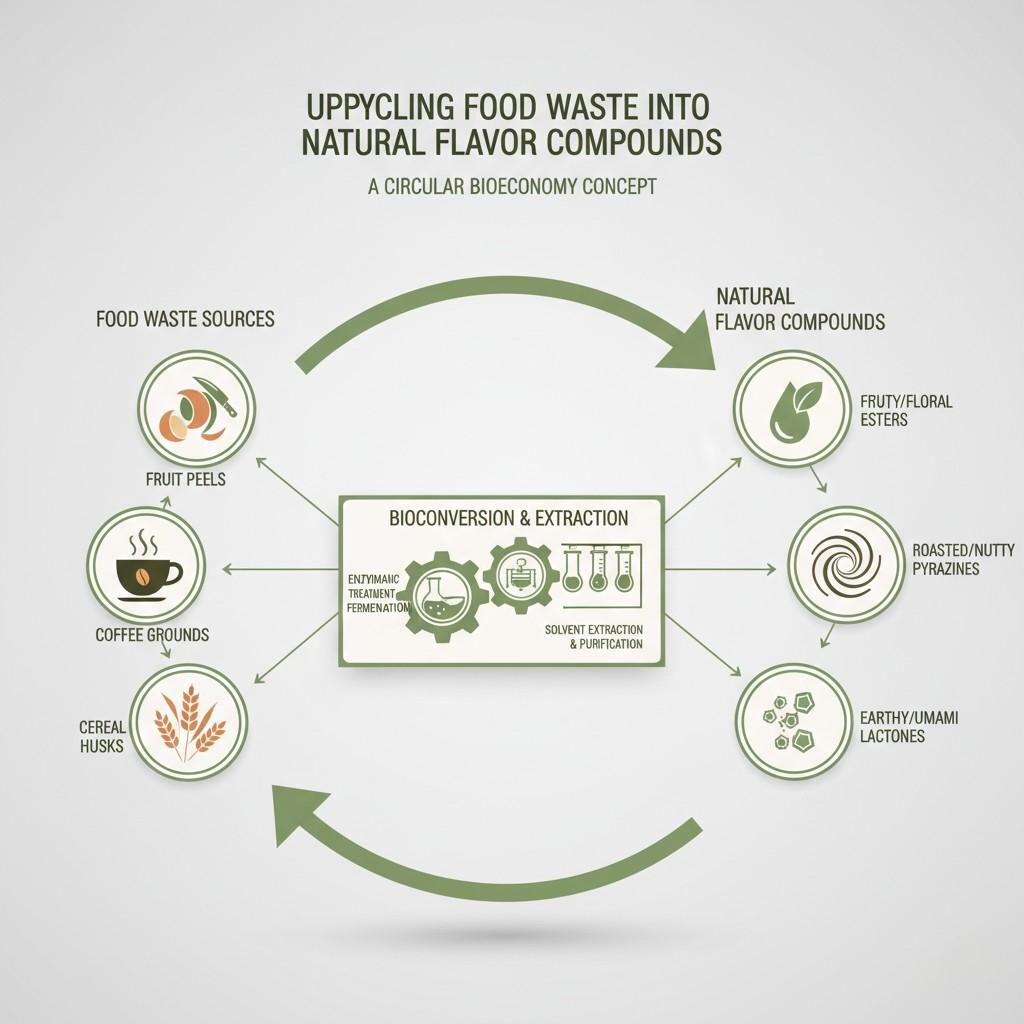

Upcycling Food Waste into Natural Flavors

In a world where sustainability drives both innovation and consumer trust, the food and beverage industry faces a dual challenge: reducing waste while creating value. One of the most promising solutions to emerge in recent years is upcycling—the process of converting food byproducts into valuable new ingredients, including natural flavor compounds.

Globally, the Food and Agriculture Organization (FAO) estimates that one-third of all food produced is lost or wasted each year, amounting to roughly 1.3 billion tons [1]. This staggering figure represents not only an environmental burden but also a lost opportunity for resource recovery. Through biotechnological innovation and flavor chemistry, manufacturers can now extract, ferment, or transform waste streams into unique, sustainable flavor ingredients that align with the growing demand for circular food systems.

This article explores how upcycling technologies are reshaping flavor manufacturing—from fruit peel-derived citrus essences to coffee ground aromatics—and how this trend offers both economic and ecological benefits for the modern food and beverage industry.

Food waste is not just an ethical or environmental issue; it represents a reservoir of functional biomolecules. Fruit peels, vegetable stems, dairy whey, cereal brans, and spent coffee grounds are rich in volatile organic compounds (VOCs), polyphenols, terpenes, and amino acids—the same building blocks used in flavor creation.

From a chemist’s perspective, these byproducts are far from “waste.” For instance:

By leveraging green chemistry and biotransformation, these materials can be refined into safe, food-grade flavor ingredients that enhance both taste and sustainability profiles.

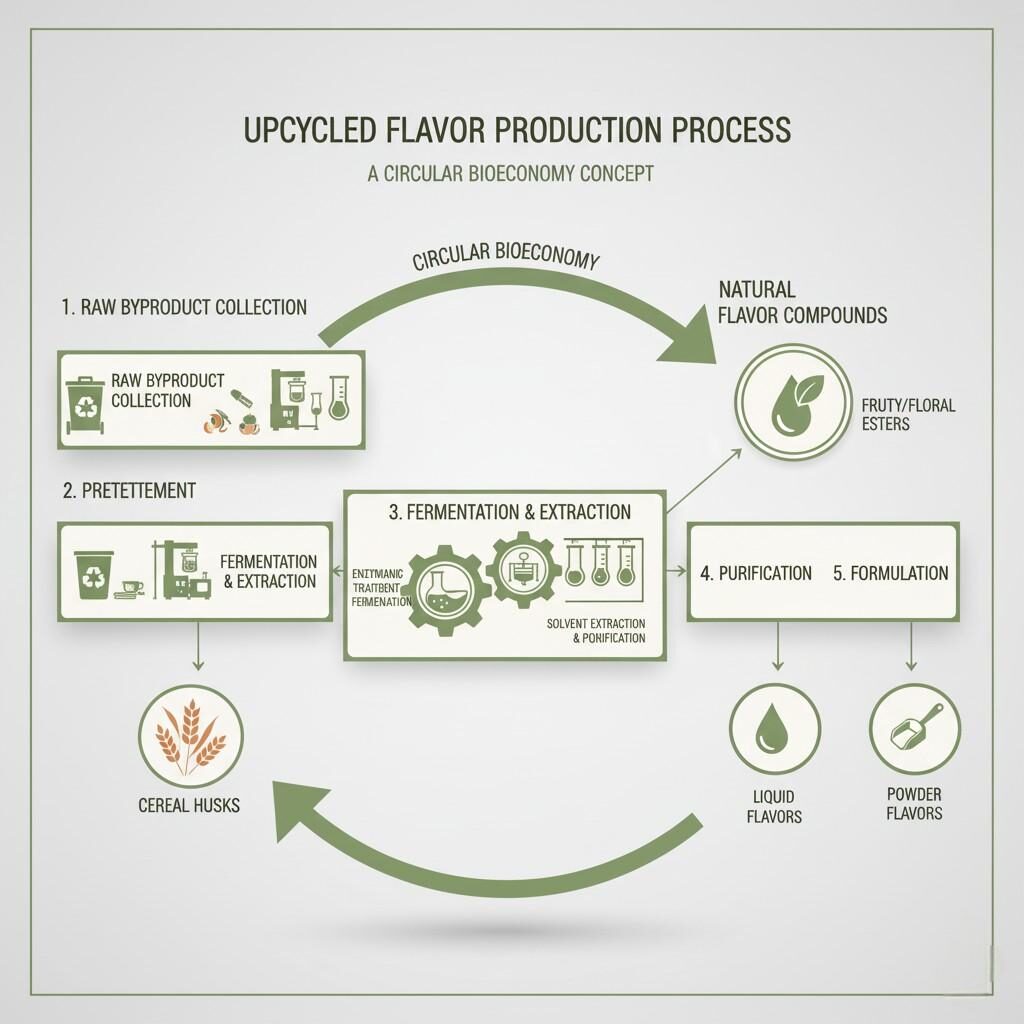

Upcycled Flavor Production Process

The first stage of upcycling focuses on isolating aromatic compounds from waste matrices. Depending on the source material, extraction techniques include:

According to a study by the U.S. Department of Agriculture (USDA), enzyme-assisted extraction from fruit processing waste increased volatile recovery yields by up to 45% compared with conventional solvent methods [2].

Microbial fermentation can transform sugars, amino acids, and organic acids in byproducts into new aromatic molecules. This approach, known as biotransformation, uses natural microbial metabolism to create complex flavor notes.

Examples include:

The fermentation route not only adds value but also aligns with the clean-label trend, as the resulting flavors are often classified as “natural” under regulatory definitions (e.g., EU Regulation No. 1334/2008).

Controlled heating of protein- and sugar-rich byproducts generates Maillard reaction flavors, providing savory, roasted, or caramelized notes. For example, spent yeast extract or cereal bran hydrolysates can be processed into rich, umami base notes suitable for soups, snacks, or sauces.

Upcycling byproducts for flavor production contributes to environmental sustainability, economic efficiency, and brand differentiation.

According to the United Nations Environment Programme (UNEP), food waste contributes nearly 8–10% of global greenhouse gas emissions [3]. By upcycling, flavor manufacturers can directly support carbon neutrality goals across supply chains.

By converting low-cost byproducts into high-value flavor ingredients, companies can achieve resource-based profitability.

For example, orange juice processors can repurpose peel residues—normally a disposal cost—into citrus oil concentrates sold to beverage and confectionery companies.

Upcycling initiatives align with global frameworks such as:

These alignments enhance brand reputation and regulatory compliance simultaneously.

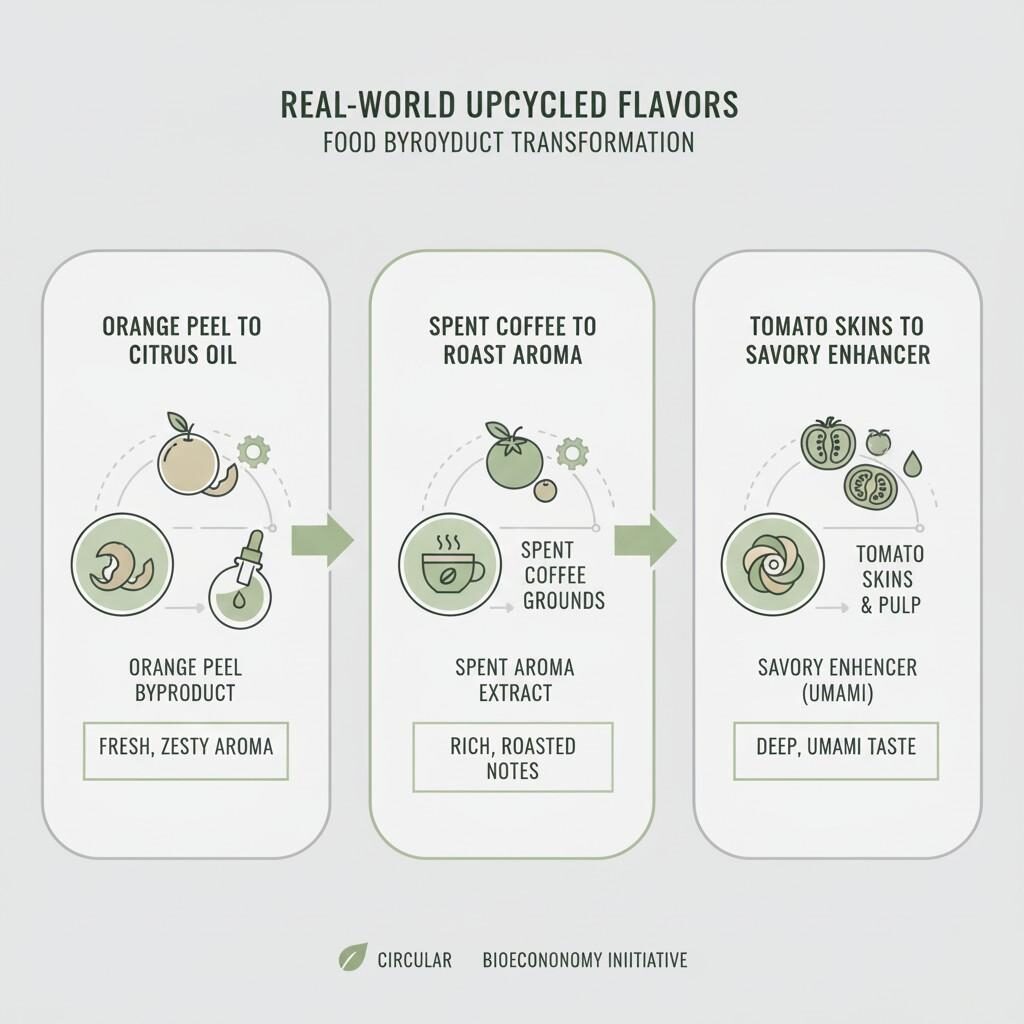

Real-World Upcycled Flavors

Citrus processing generates millions of tons of peel annually. Through cold pressing and steam distillation, manufacturers extract essential oils rich in limonene and citral. These are then purified or encapsulated for flavor applications in beverages, candies, and baked goods.

Spent coffee grounds, abundant in the instant coffee industry, contain residual melanoidins and aromatic aldehydes. Solvent-free extraction yields natural “roast” base notes ideal for plant-based beverages or confectionery.

Whey, a byproduct of cheese production, contains lactose and proteins that can undergo enzymatic hydrolysis and Maillard reactions, yielding sulfur-containing aroma compounds typical of brothy or umami profiles.

Rice, wheat, and oat brans contain phenolic precursors that, when fermented, produce nutty, toasty, or caramelized flavor compounds. These have found use in cereal bars, bakery items, and alternative dairy products.

Each of these examples demonstrates the potential for circular flavor innovation—creating sensory and environmental value simultaneously.

Upcycling for flavor innovation depends heavily on interdisciplinary R&D across flavor chemistry, biotechnology, and process engineering.

Techniques like gas chromatography–mass spectrometry (GC–MS) and headspace analysis identify volatile profiles in byproducts, allowing targeted extraction and optimization.

Once extracted, upcycled flavors are often microencapsulated using maltodextrin or gum arabic to improve stability, solubility, and controlled release—preventing oxidation and extending shelf life.

Emerging AI-driven tools are enabling predictive modeling for fermentation conditions and reaction kinetics, maximizing yield and aroma complexity while minimizing resource use.

According to a 2023 report by the World Economic Forum (WEF), AI-assisted bioprocess optimization can increase process efficiency by 20–30%, accelerating the development of sustainable food ingredients [4].

Consumers are increasingly aware of sustainability and ingredient origins. This awareness shapes market demand in several key ways:

A study by the Upcycled Food Association found that products labeled as “upcycled” experience 50% faster sales growth than conventional alternatives in similar categories.

Flavor manufacturers, therefore, have a compelling incentive to innovate in this space—not only to meet sustainability goals but also to respond to shifting consumer psychology.

While the concept of upcycled flavors is appealing, food safety and quality assurance remain paramount. Key measures include:

By integrating quality control from source to formulation, manufacturers can ensure that upcycled flavors meet or exceed conventional safety benchmarks.

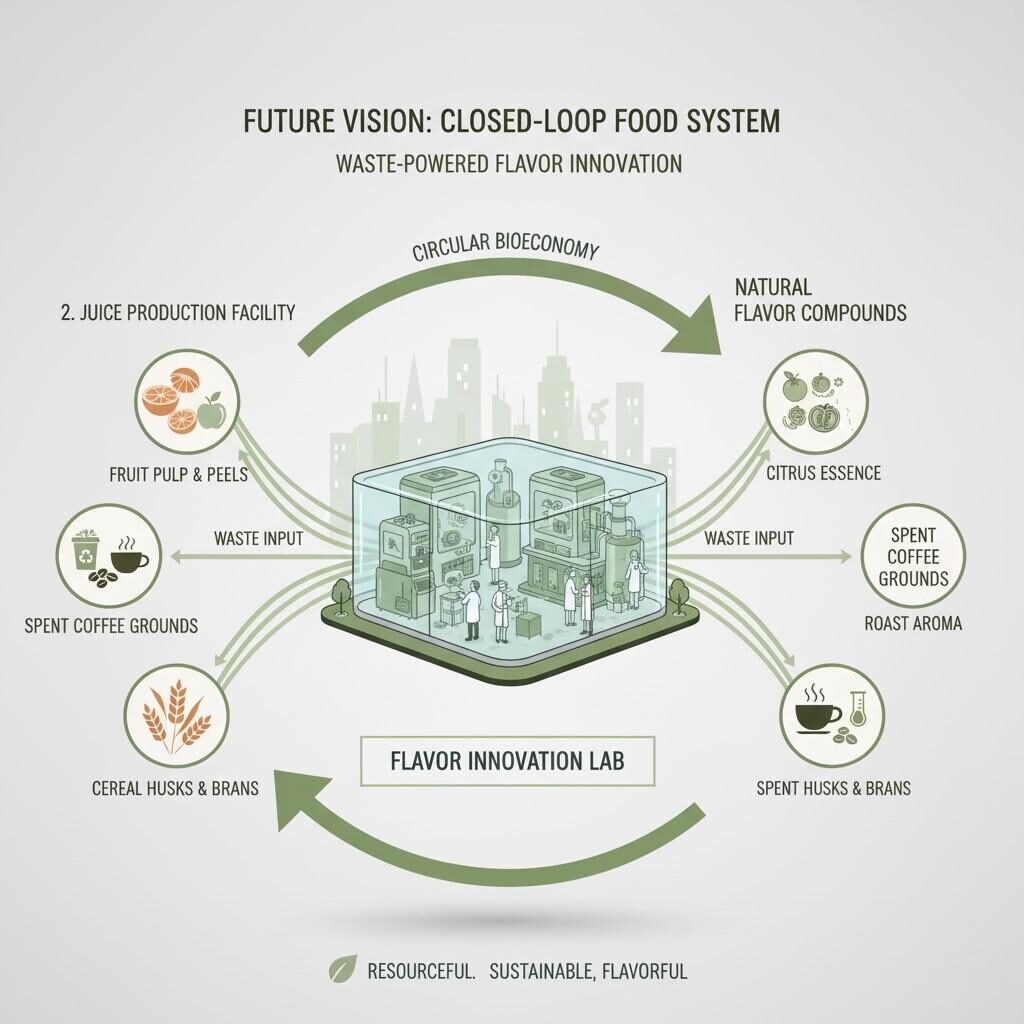

Future: Closed-Loop Food System

As technology, consumer awareness, and sustainability policies converge, upcycling is poised to become a core pillar of flavor R&D. Future advancements may include:

The transformation from waste to value reflects a broader movement toward circular flavor innovation—where every byproduct becomes a potential source of sensory creativity and sustainability leadership.

The upcycling of food byproducts into innovative flavor ingredients exemplifies how science, sustainability, and sensory design can coexist harmoniously. Beyond environmental benefits, it opens a new frontier for natural flavor discovery—where underused materials reveal hidden aroma treasures.

As the food and beverage industry transitions to a circular model, upcycled flavors will play a central role in defining the next generation of eco-conscious product innovation. For manufacturers, adopting these technologies is not just a sustainability initiative—it’s a competitive advantage and a statement of purpose.

At CUIGUAI Flavoring, we specialize in creating high-performance natural flavors through advanced R&D and sustainable sourcing. Our portfolio includes upcycled and plant-derived flavor ingredients designed to enhance taste while supporting environmental goals.

Whether you are exploring new flavor concepts or developing sustainable product lines, our technical team can assist you with custom formulations, extraction solutions, and stability optimization.

Partner with CUIGUAI Flavoring to discover how upcycled flavors can enhance your products’ sustainability, sensory appeal, and market impact.

👉 Reach out today for technical collaboration or a free sample consultation.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.cn】

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.