Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 29, 2025

Food Tech Lab Innovation

In today’s competitive food and beverage market, brands are under unprecedented pressure to deliver products that are delicious, consistent, stable, compliant, and differentiated. Flavor quality is unquestionably important—but success in modern product development requires far more than a bottle of flavor.

What truly drives competitive advantage is the technical support behind the flavor: the analytical chemistry, application science, sensory methodology, regulatory guidance, and formulation expertise that ensure a flavor performs optimally in a specific product matrix.

Most successful global brands have one thing in common: they treat their flavor manufacturer not only as a supplier, but as an extension of their technical team. This shift from transactional purchasing to technical collaboration is reshaping how food and beverage products are developed, optimized, and scaled.

This article explores the often-overlooked but essential value of technical support from flavor manufacturers, and how these services reduce development time, cut costs, improve product quality, and help your brand succeed in the market.

The insights below reflect real-world industry practices and are supported by reliable institutions, scientific references, and regulatory resources.

Global trends such as clean-label reformulation, sugar reduction, plant-based products, functional beverages, and multicultural flavor expansions have made formulation significantly more complex. According to the Institute of Food Technologists (IFT), modern product development cycles have accelerated dramatically, requiring companies to innovate faster while managing greater regulatory and sensory expectations .

But internal R&D teams are often stretched thin. They must balance:

In this environment, a flavor manufacturer with advanced technical support capabilities can directly improve a brand’s tactical agility and strategic resilience.

Even the highest-quality flavor will not perform well if:

This means no flavor is universally optimal by default.

It must be engineered, tested, and optimized for its application.

This is why technical support is not optional—it is essential.

Flavor and ingredient regulations differ significantly among countries. In the United States, flavor materials must comply with FDA Title 21 CFR, FEMA GRAS status, and good manufacturing practices (GMP) guidelines . Globally, frameworks such as EFSA, FSANZ, and China GB standards add additional complexity.

A flavor manufacturer’s regulatory team ensures that:

For multi-country brands, regulatory technical support can prevent costly relabeling, shipment delays, or market rejections.

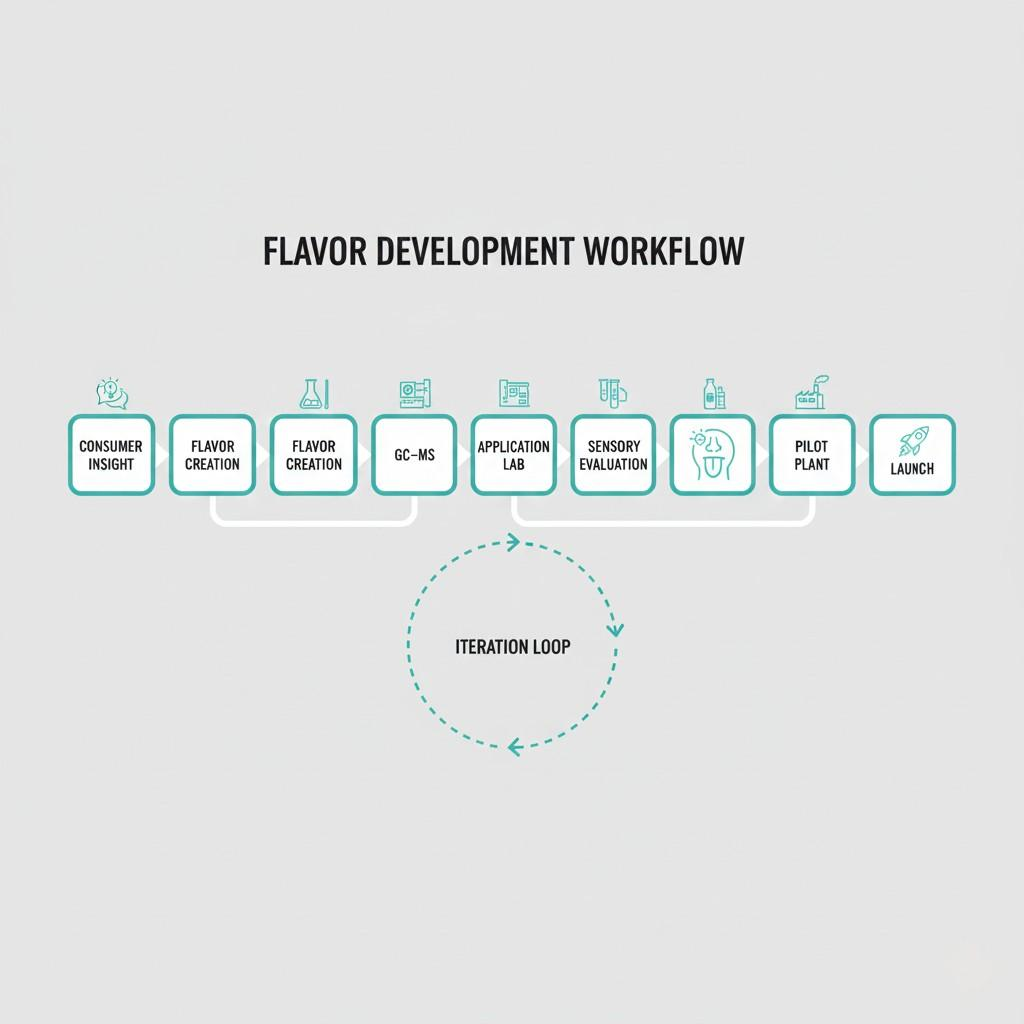

Flavor Development Workflow

Flavor manufacturers with strong technical teams offer far more than raw materials—they provide comprehensive, science-backed support that improves every stage of product development.

Application labs replicate real production conditions, allowing flavors to be tested in targeted environments before full-scale production. Application scientists evaluate how flavors behave in:

This testing identifies the ideal flavor load, solubility behavior, process impact, and post-processing sensory performance.

Application testing dramatically reduces the risk of unexpected flavor failure during scale-up.

Advanced flavor manufacturers use Gas Chromatography–Mass Spectrometry (GC–MS) to analyze:

GC–MS data helps identify the molecular reasons behind sensory perceptions and supports the design of more stable, robust flavors.

Academic literature consistently shows GC-MS as one of the most reliable methods for evaluating food aroma systems, particularly in beverages and dairy matrices (Springer Food Chemistry research) .

Sensory scientists trained in standardized methodologies (e.g., Quantitative Descriptive Analysis, triangle tests, hedonic scoring) help brands:

Olfactory–memory research, such as the “Olfaction” summary in Wikipedia, further illustrates the strong role aroma plays in consumer emotion and recall, reinforcing the need for systematic sensory evaluation during development .

A skilled technical team can quickly resolve common formulation issues such as:

Rapid solutions prevent costly delays and ensure product integrity.

Flavor manufacturers help brands navigate:

This is increasingly critical as brands move toward transparency and simplified ingredient lists.

Consumers want healthier products, but reducing sugar, salt, or fat often damages product flavor or mouthfeel.

Flavor manufacturers’ R&D teams develop:

These tools help brands deliver indulgence with fewer calories, while maintaining consumer satisfaction.

Technical teams evaluate how flavors change during:

Understanding volatile compound degradation pathways ensures flavors remain stable throughout the product’s life.

Advanced flavor manufacturers assist directly with:

This ensures smooth integration between R&D, production teams, and flavor performance in real factory environments.

Without expert support, teams may waste weeks adjusting flavor dosages, addressing off-notes, or reworking formulas. Technical guidance significantly shortens development cycles.

Application testing minimizes failures during:

This reduces raw material consumption and lowers overall production cost.

Regulatory teams ensure:

This prevents delays and reduces administrative burden.

A flavor manufacturer with strong technical capability can tailor flavors for regional matrices while maintaining identical sensory perception, supporting global brand alignment.

With technical partners monitoring stability, reactivity, and formulation challenges, brands face fewer surprises during production or market launch.

Brands with strong flavor manufacturer support launch new products faster and respond more effectively to market trends.

Optimized flavor systems produce:

These attributes directly influence repeat purchase behavior.

When a flavor manufacturer understands your sensory DNA, they can maintain consistency across:

This strengthens brand recognition.

Technical teams help ensure flavor performance remains stable across:

This consistency is essential for global brands.

High-intensity vitamins created bitterness and metallic off-notes.

Technical support provided masking agents, sweetness modulators, and optimized citrus top notes, restoring product appeal.

A vanilla flavor lost intensity during pasteurization.

Application scientists reformulated the vanilla base with heat-resistant compounds, preserving aroma after dairy processing.

Flavor top notes evaporated during baking. Encapsulated flavors were recommended, creating a longer-lasting sensory experience.

Descriptive Sensory Analysis

Look for:

Your partner should offer specialists in:

The best teams deliver:

Look for partners experienced in:

Flavor is more than a sensory component—it is a strategic asset.

And behind every successful flavor lies a powerful combination of:

Food and beverage brands that embrace strong technical partnerships with their flavor manufacturers consistently outperform competitors in speed, quality, and consumer loyalty.

Flavor Systems for Brand Identity

If you are developing new food or beverage products, reformulating existing SKUs, or seeking solutions for off-notes, stability, or processing challenges, our technical team is ready to support you.

We provide:

✔ Custom flavor development

✔ Application testing for beverages, dairy, bakery, snacks, plant-based products, and more

✔ GC–MS analysis and sensory evaluation

✔ Clean-label and regulatory documentation

✔ Free samples for qualified corporate projects

Contact us today to begin your next innovation project.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.cn]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.