Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 22, 2025

Cultivated Meat Lab

The future of food is being reshaped by science — and nowhere is this transformation more profound than in the rise of cell-based and cultivated meats. These innovative protein sources, produced through cell cultivation rather than traditional animal farming, promise a more sustainable, ethical, and efficient food system.

However, while cultivated meats replicate the cellular structure and nutrition of conventional meat, one critical sensory factor still defines their success: flavor.

Flavor isn’t just a culinary detail — it’s the emotional and cultural bridge that determines consumer acceptance, brand differentiation, and market viability. As the global food industry accelerates toward commercialization of lab-grown meat, flavor science stands at the heart of this emerging category.

This article explores the technical role of flavor development in cell-based meats, from molecular aroma design to sensory optimization and process integration — offering an authoritative guide for professionals in food innovation, formulation, and flavor manufacturing.

Cell-based or cultivated meat is produced by growing animal cells directly in a controlled environment, eliminating the need to raise and slaughter livestock. The process typically involves four major stages:

According to the U.S. Food and Drug Administration (FDA), cultivated meat products that meet safety and compositional standards can be regulated similarly to conventional animal products [¹]. This dual oversight by the FDA and USDA ensures that cell-based meat can be safely commercialized under food-grade production practices.

Yet, one of the biggest challenges facing this breakthrough technology is achieving the authentic sensory profile of traditional meat, including its aroma, taste, and mouthfeel.

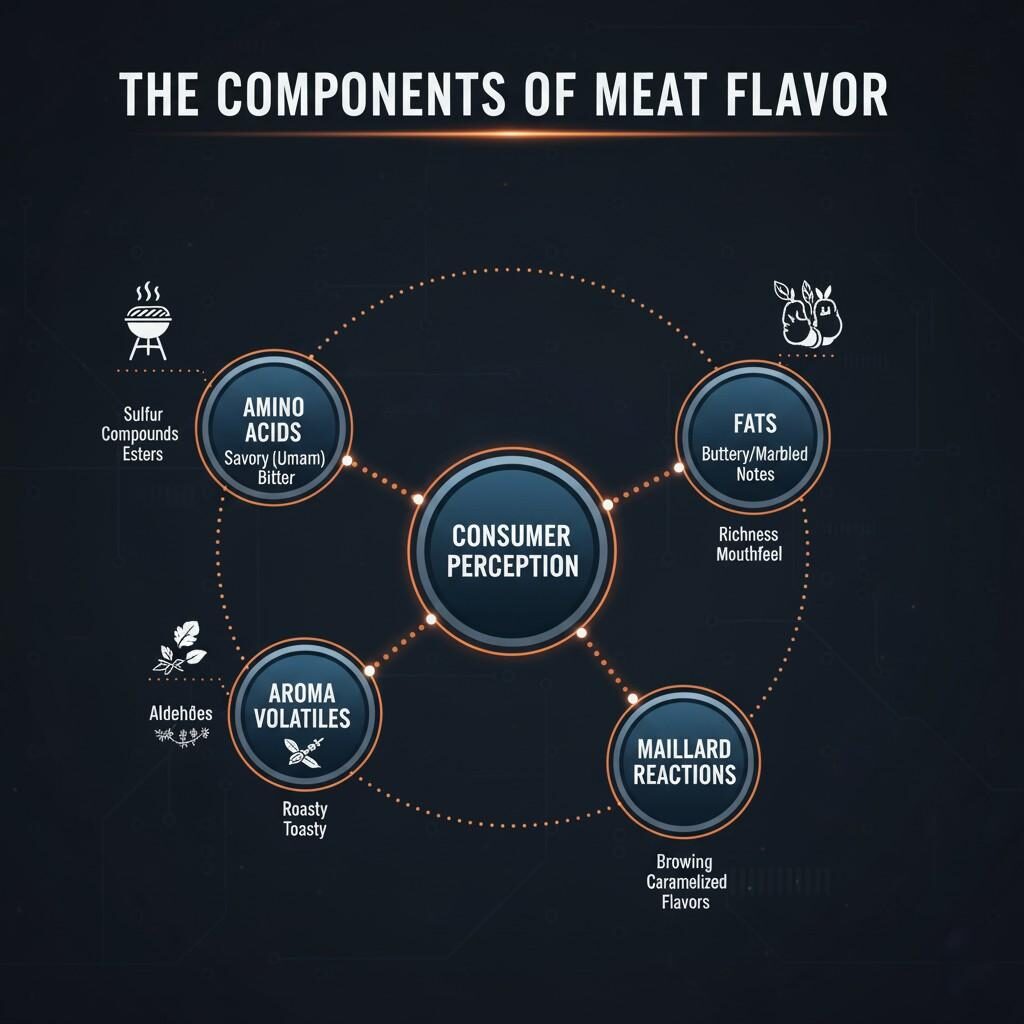

Meat Flavor Components Infographic

While the texture of cultivated meat can now closely mimic real muscle tissue through 3D scaffolding and bioprinting, flavor reproduction remains far more complex.

Traditional meat flavor arises primarily from:

Maillard reactions between amino acids and reducing sugars during cooking.

Lipid oxidation generating volatile compounds like aldehydes, ketones, and alcohols.

Thermal decomposition of sulfur compounds, producing savory or “meaty” notes.

These processes depend on intramuscular fat, heme proteins (myoglobin), and amino acid precursors — all of which are difficult to reproduce naturally in cell-culture environments.

Even if cultivated meat is nutritionally identical to animal meat, consumers will reject it if it lacks the aroma intensity, juiciness, and aftertaste they associate with traditional cooking.

A 2023 report by The Good Food Institute (GFI) found that flavor perception was the #1 sensory factor influencing consumer acceptance of cultivated meat across global markets [²].

Thus, developing authentic, stable, and cooking-responsive flavor systems is essential for the commercial success of these emerging protein sources.

The development of cultivated meat flavors requires interdisciplinary expertise — bridging food chemistry, cellular biology, and sensory science.

Flavorists now collaborate with biotechnologists to address challenges that were once purely culinary:

At CUIGUAI Flavoring, we focus on GC–MS–based aroma analysis and reaction flavor design, enabling the replication of complex meaty aromas within cell-based and plant-based protein systems.

In conventional meat, flavor richness comes largely from fat oxidation products — such as aldehydes (hexanal, nonanal), lactones, and pyrazines. Cultivated meats often contain less lipid content or use plant-based fat alternatives, leading to lower aromatic complexity.

Solution:

Heme proteins such as myoglobin are responsible for both the color and umami flavor of cooked meat. Cultivated systems may express less myoglobin due to oxygen-controlled growth conditions.

Solution:

The Maillard reaction generates hundreds of flavor molecules — including pyrazines, thiazoles, and furans — during cooking. Cultivated meats may lack sufficient reducing sugars or amino acids to trigger these reactions fully.

Solution:

Because cultivated meat production involves cell media and bioreactor conditions, any added flavor precursors must remain chemically stable and non-toxic during growth.

Key factors to consider:

Flavor engineers work with bioprocess specialists to determine when and how flavors or precursors should be introduced — whether post-harvest or pre-cooking — for maximum sensory impact.

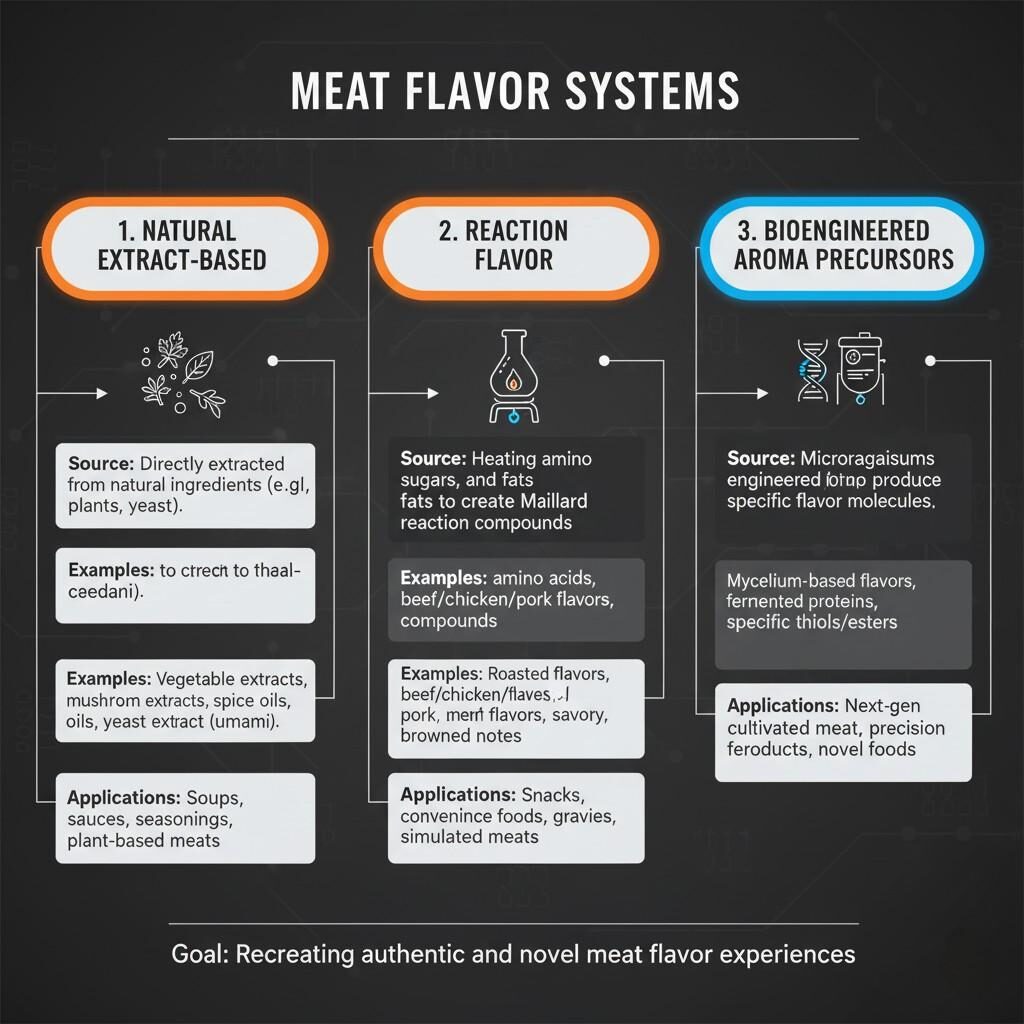

Meat Flavor Systems Comparison

These rely on botanical extracts, yeast hydrolysates, or enzymatically treated proteins to mimic the savory complexity of cooked meat.

Yeast extracts: Deliver umami and nucleotides (IMP, GMP).

Hydrolyzed vegetable proteins (HVP): Provide roasted and soy-meaty notes.

Spice oleoresins: Add top notes (e.g., garlic, onion, black pepper).

These systems are ideal for clean-label formulations, aligning with natural positioning.

Reaction flavors are created by controlled heating of reducing sugars and amino acids, replicating the Maillard browning process in real meat cooking.

Advantages:

Formulators often use cysteine, threonine, ribose, and sulfur donors to craft balanced meaty volatiles such as 2-methyl-3-furanthiol, a signature beef note.

Emerging biotechnology now enables the microbial biosynthesis of flavor molecules identical to those formed in cooked meat. For instance:

These approaches align with the precision fermentation technologies already used in cultivated meat production — creating an integrated “bio-flavor” model for the next generation of food innovation.

Flavor success isn’t judged only by chemistry — it’s validated by sensory response.

Professional panels evaluate parameters like:

Comparative testing between cultivated vs. traditional meats helps flavorists adjust profiles for parity.

Cross-market studies show regional differences in preferred flavor notes:

Understanding these cultural nuances allows flavor manufacturers to localize global cultivated meat launches effectively.

The timing and method of flavor integration greatly affect the final sensory experience.

Encapsulation materials may include modified starch, maltodextrin, or lipid microcapsules, ensuring controlled release and oxidative protection.

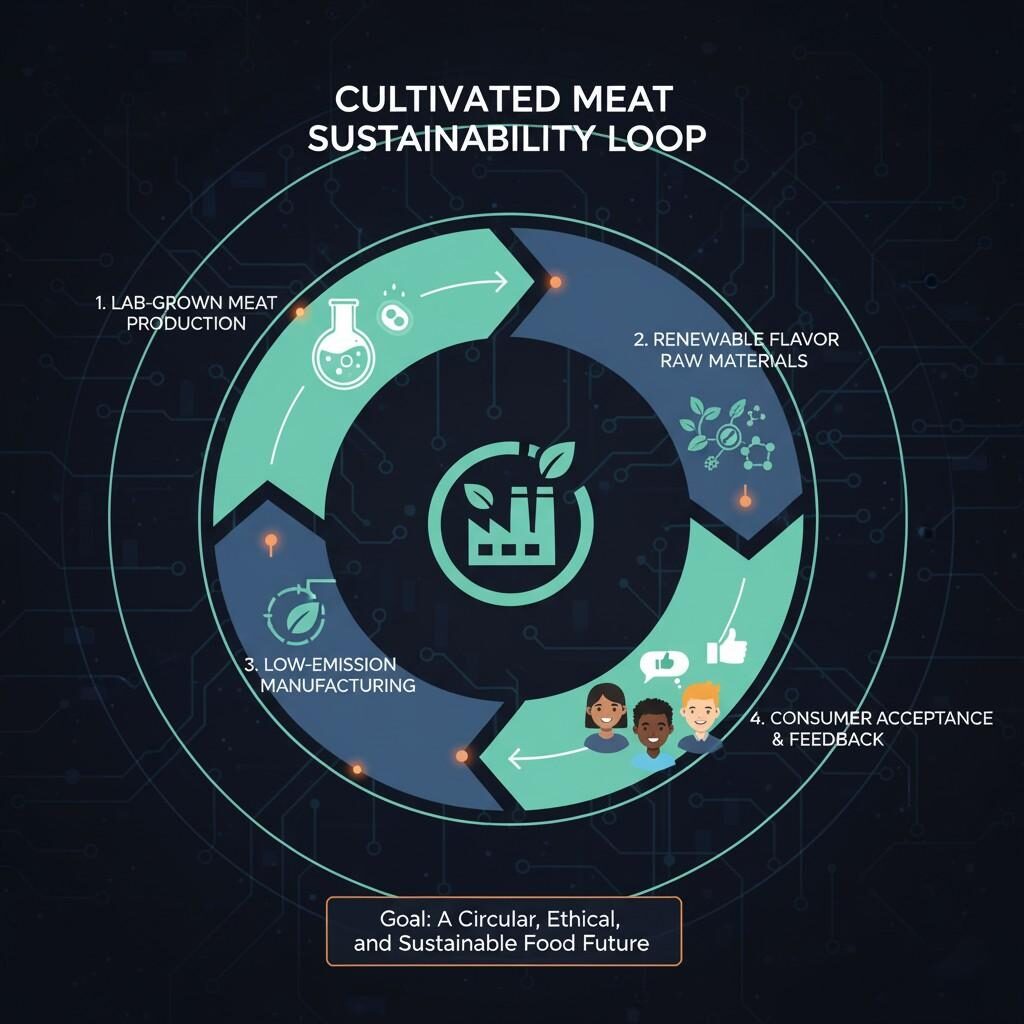

Cultivated Meat Sustainability Loop

Cultivated meat already addresses animal welfare and carbon footprint reduction, but flavor systems must also align with the same ethical and environmental goals.

Using renewable, plant-derived aroma molecules reduces dependency on petrochemical synthesis while supporting clean-label claims.

Reaction flavors can be produced under low-temperature enzymatic catalysis, minimizing carbon emissions and preserving delicate aroma notes.

Modern consumers expect clarity about ingredient origin and manufacturing processes. Partnering with certified flavor manufacturers ensures compliance with EU, FDA, and Chinese GB standards while maintaining trust.

A flavor R&D team aimed to replicate the flavor of freshly grilled chicken breast for a cultivated product.

The final flavor system offered authentic, stable, and label-friendly results compatible with cultivated meat texture and processing — demonstrating the feasibility of precision flavor engineering in this domain.

As cultivated meats move from pilot labs to commercial shelves, flavor will define competitive success.

Future directions include:

According to the Food and Agriculture Organization (FAO), global alternative protein production could reach 10% of total meat supply by 2035, with flavor technology being the key enabler of consumer acceptance [³].

The convergence of biotechnology, sensory analytics, and flavor chemistry will transform how the world perceives and enjoys sustainable proteins.

Cell-based and cultivated meats mark a historic turning point in food innovation — bridging sustainability with sensory excellence. Yet, without authentic, well-engineered flavors, even the most advanced proteins risk falling short of consumer expectations.

At CUIGUAI Flavoring, we combine GC–MS aroma profiling, Maillard reaction engineering, and biofermentation-derived flavor technologies to craft solutions tailored for emerging protein sources. Our expertise empowers food innovators to deliver not only ethical nutrition but unforgettable taste experiences that define the next era of gastronomy.

Contact our specialists for technical collaboration, flavor formulation support, or sample requests tailored to your next-generation food project.

📩 Request a Free Sample or Technical Exchange

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.cn】

[¹] U.S. Food and Drug Administration (FDA). Regulatory Oversight Framework for Cultivated Meat, 2023.

[²] The Good Food Institute (GFI). Consumer Insights on Cultivated Meat Perception, 2023.

[³] Food and Agriculture Organization (FAO). The Future of Sustainable Protein Systems, 2024.

[⁴] Institute of Food Technologists (IFT). Flavor Chemistry in Alternative Proteins, Journal of Food Science, Vol. 89, 2024.

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.