Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 28, 2025

Flavor Innovation Lab

The global food and beverage market is expanding faster than ever, driven by rising consumer expectations for premium taste, clean-label transparency, functional performance, and rapid product variety. Brands today are no longer competing solely on flavor quality—they are competing on speed, consistency, innovation pipelines, and the ability to deliver seamless sensory experiences across categories.

In this environment, a flavor supplier is no longer enough.

What companies truly need is an integrated flavor solutions partner: a full-service extension of their R&D team capable of managing flavor development, regulatory compliance, stability testing, sensory optimization, application engineering, and long-term product lifecycle support.

This article explores how full-service flavor partners accelerate growth, reduce costs, and enhance product differentiation in a competitive marketplace. Drawing from industry research, regulatory guidance, and proven commercial practices, we outline how integrated flavor solutions function and why manufacturers across beverages, dairy, confectionery, and plant-based categories increasingly depend on these partnerships.

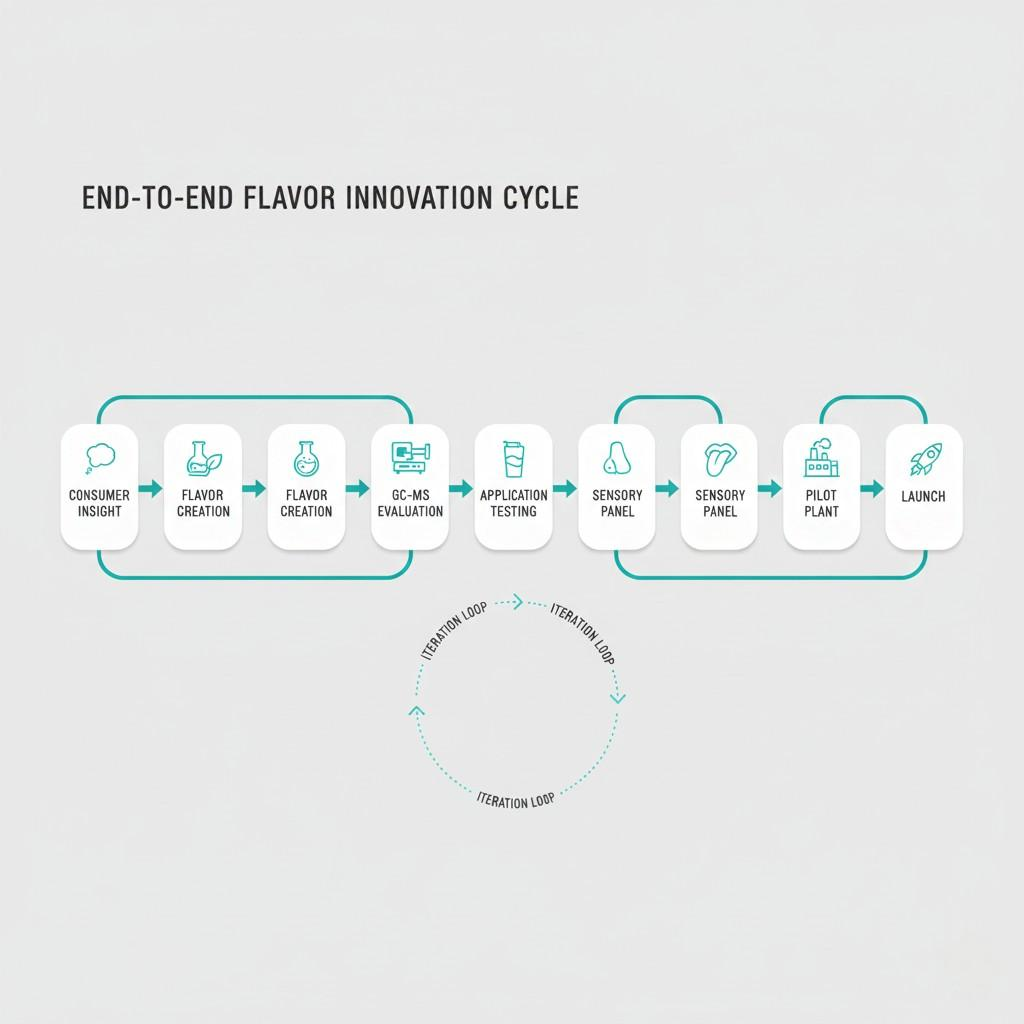

Most food and beverage companies today face a common issue: the development cycle involves multiple disconnected steps—

When these steps are outsourced to multiple suppliers or conducted with insufficient technical support, projects become slow, inconsistent, and unpredictable.

Longer time-to-market, higher cost of reformulation, and increased risk of consumer rejection.

An integrated flavor partner eliminates these disconnects by providing a continuous technical workflow, from concept creation to commercial launch.

According to a report by McKinsey, consumer F&B trends now evolve 2–3× faster than a decade ago as digital channels accelerate feedback cycles and shorten trend lifetimes. Brands must evolve quickly in areas such as:

Yet most internal R&D teams are not scaled for rapid iteration.

This gap is where integrated flavor partners provide unparalleled value.

A full-service partner begins with scientific flavor design. This includes:

According to the U.S. Food & Drug Administration (FDA), flavoring substances used in food applications must comply with the FEMA GRAS list and FDA Title 21 regulations . An integrated partner ensures all compounds meet these requirements automatically.

Your team focuses on creativity and product positioning—not technical compliance or molecular analysis.

Flavor performance changes dramatically depending on pH, fat levels, sugar content, heat processing, and packaging materials. A full-service partner understands these variables and provides customized application engineering for:

The same flavor formula can behave differently in different systems.

Integrated partners optimize flavor release, stability, and masking for each application before scale-up, reducing product risk.

Integrated flavor houses provide rapid, iterative development cycles—often including:

Academic sources emphasize how multidimensional sensory data correlates strongly with consumer acceptance, especially in categories like beverages and confections (e.g., the Institute of Food Technologists) .

R&D teams achieve more accurate formulations in fewer iterations, reducing both time and development cost.

A true integrated partner provides:

This eliminates the bottlenecks commonly caused by compliance challenges, especially for brands operating in multiple countries.

Flavor degradation pathways include:

Research in food chemistry shows that volatile compound stability is one of the most critical contributors to long-term product quality (Springer Food Chemistry Journal) .

Integrated partners help predict shelf-life behavior, adjust formulas, and validate performance—ensuring consistent quality from production to end-user consumption.

Traditional development cycles may require:

An integrated partner can compress this into a few weeks, sometimes days.

In competitive categories—especially beverages, ready-to-drink coffee, and functional drinks—speed is a major competitive driver.

Brands often overlook the hidden costs of fragmented development:

An integrated partner consolidates these functions, producing measurable cost reductions over time.

Flavor is one of the most emotionally powerful drivers of brand loyalty.

As noted in psychology and marketing research, olfactory cues play a major role in sensory memory formation (see “Olfaction” – Wikipedia) .

An integrated partner ensures:

This is especially critical for national and international F&B brands.

Integrated partners operate across multiple product categories, which allows them to transfer insights from one domain to another:

This cross-pollination is difficult to achieve internally but becomes natural when working with a diversified flavor lab.

Flavor Innovation Cycle

Your partner begins by gathering:

This bridges the gap between marketing goals and R&D capabilities.

This includes building:

R&D teams combine analytical chemistry with sensory design—something only an integrated flavor partner can offer.

Application specialists convert flavor formulas into real-world prototypes that match your manufacturing conditions:

Your internal team receives ready-to-test samples that are production realistic.

Sensory Evaluation Panel

This step includes:

Integrated partners refine formulas until they match the desired product experience.

This involves:

Only suppliers with integrated systems can provide consistent large-scale production without altering sensory performance.

Including:

At this stage, the product launches with confidence in its technical integrity and market readiness.

(Note: These examples are generic and anonymized to remain industry-compliant.)

A startup beverage brand struggled with bitterness from botanical extracts and vitamin blends. With a full-service flavor partner providing masking flavors, sweetness modulators, and rapid sensory prototypes, the team reduced development time from 20 weeks to 8.

A multinational yogurt brand needed consistent strawberry flavor across five countries with different dairy bases. Through integrated flavor engineering and regional customization, they achieved identical taste perception across all markets.

An oat milk producer needed solutions for earthy and astringent off-notes. An integrated partner used enzymatic flavor modulators and lipid-friendly top notes to neutralize off flavors while improving roundness and creaminess.

The best partner:

This is not a vendor—

This is a long-term extension of your R&D and brand team.

Unified Flavor Branding

Food and beverage companies today must move faster, innovate deeper, and differentiate more meaningfully.

An integrated flavor partner empowers them to:

In an era defined by rapid consumer change, full-service flavor solutions are no longer optional—they are essential for sustainable growth.

If you are developing new products or optimizing existing formulations, our R&D team is ready to collaborate.

We provide:

✔ Customized flavor development

✔ Application testing for beverages, dairy, savory, bakery, and more

✔ Rapid prototyping (24–72 hours)

✔ Regulatory documentation support

✔ Free samples for qualified corporate projects

Contact us today to start your flavor innovation journey.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.cn]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.