Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Feb 09, 2026

Scientific Precision

In the intricate world of food and beverage development, the spotlight often falls on the star players: the volatile aroma chemicals and complex extracts that define a flavor profile. We obsess over the perfect ratio of esters for a strawberry note or the precise extraction method for a bourbon vanilla. However, the unsung heroes of flavor creation—the stage upon which these stars perform—are the solvents.

Often referred to interchangeably as “carriers,” solvents are far more than passive diluents. For the professional flavorist and the food scientist, understanding flavor solvents is not merely about stoichiometry; it is about mastering the mechanics of flavor delivery, stability, and perception. A precisely crafted flavor profile can fail spectacularly in the final application if paired with the wrong carrier system.

As a professional manufacturer of industrial flavors, we recognize that the “solvent system” is the backbone of any successful formulation. This comprehensive guide delves into the technical realities of flavor solvents, exploring the chemical criteria for selection, the unique properties of industry standards, and the regulatory landscape governing their use.

If flavor compounds are the “message,” the solvent is the “medium.” In its pure form, a flavor concentrate—a dense mixture of aldehydes, ketones, esters, and essential oils—is often unusable. It may be too potent for direct dosing, too viscous to handle on a production line, or chemically unstable when exposed to oxygen or light.

The primary role of a solvent is indeed dilution, standardizing the flavor strength to ensure consistent dosing in industrial food manufacturing. But the functional role goes much deeper:

Many potent aroma chemicals are solids at room temperature (e.g., Vanillin, Maltol) or highly viscous resins. A solvent must effectively dissolve these diverse chemical classes into a homogeneous, stable liquid phase that does not separate over time.

This is perhaps the most critical function. The solvent dictates how the flavor is “carried” into the food matrix and, subsequently, how it is released in the mouth. The interaction between the solvent, the food base (fat vs. water), and the saliva determines the partition coefficient of the flavor compounds.

A highly volatile solvent like ethanol may provide an immediate “burst” of top notes upon opening a beverage, while a heavier solvent like glycerin might retard the release, offering a longer-lasting sensation in a confectionery application. The choice of carrier fundamentally shapes the temporal sensory experience.

Solvents play a vital role in protecting labile aroma compounds. They can act as antioxidants or buffers, shielding delicate citrus oils from oxidation or preventing hydrolysis in acidic environments. Furthermore, certain solvents with low water activity (Aw), such as propylene glycol, exhibit antimicrobial properties, contributing to the microbiological stability of the finished flavor system.

Selecting the appropriate solvent is a multi-dimensional puzzle. There is no single “best” solvent; there is only the best solvent for a specific application. When we formulate for our clients, we evaluate several critical physicochemical parameters.

“Like dissolves like” is the fundamental rule of flavor chemistry. Flavor compounds range from highly polar (water-soluble acids and alcohols) to highly non-polar (oil-soluble terpenes and fats).

The solvent must match the polarity of the flavor payload to ensure complete dissolution. If you try to dissolve citrus essential oils (non-polar) directly into water (polar), you get immediate separation—an emulsion, not a solution. The flavorist must choose a solvent that sits in the “Goldilocks zone,” compatible enough with the aroma chemicals to hold them, but compatible enough with the final food product to disperse evenly.

Viscosity is a practical constraint in manufacturing. While a thick, syrupy carrier might offer excellent flavor retention in hard candy, it can be a nightmare for automated liquid dosing systems in a high-speed beverage bottling plant. We must balance sensory needs with the realities of our clients’ production equipment.

Ideally, a solvent should be organoleptically inert—colorless, odorless, and tasteless. It should not contribute its own notes or mask the delicate aromatics it carries. While no solvent is perfectly invisible, some are more neutral than others. Ethanol, for example, has a distinct “bite” and aroma at high concentrations, which must be accounted for in the final profile.

Viscosity Comparison

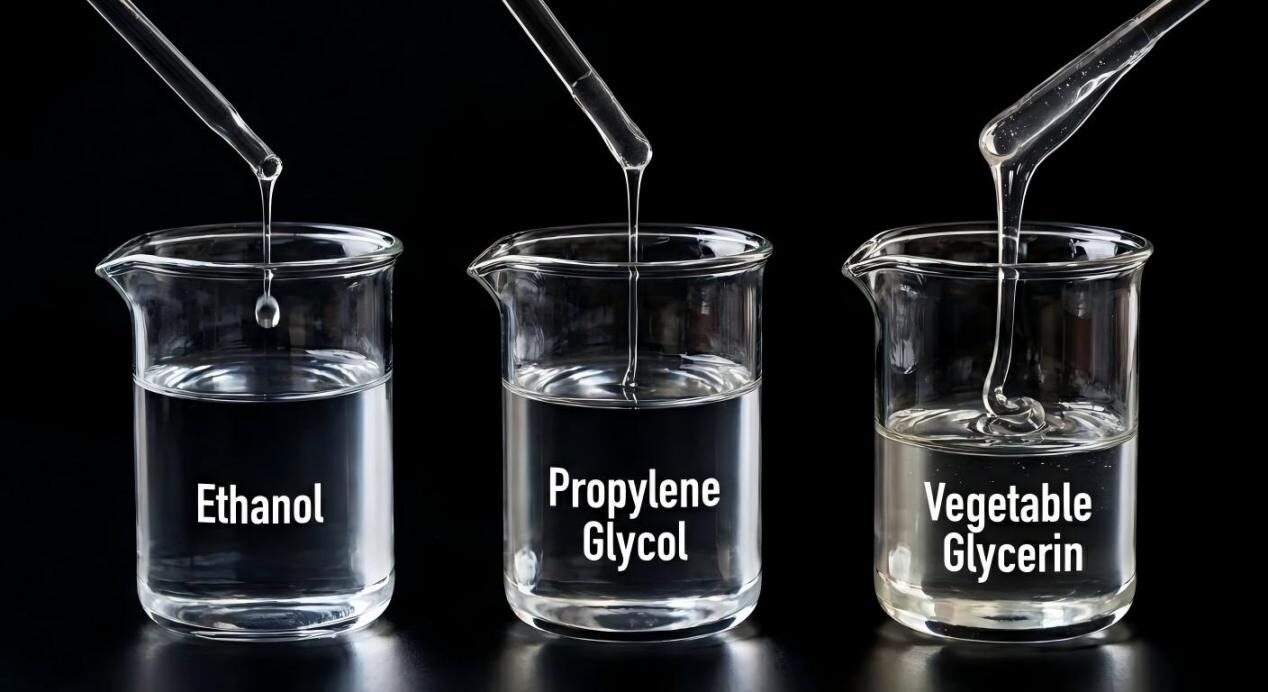

While the list of potential chemical solvents is vast, the food industry relies on a select group of trusted, well-regulated workhorses. Understanding the distinct personality of each is crucial for effective formulation.

Water is the most natural and cost-effective solvent. However, its utility in flavor formulation is severely limited by its high polarity.

Ethanol is a cornerstone of traditional flavor extraction (tinctures, extracts) and modern formulation. It is unique because it possesses both polar and non-polar character, allowing it to bridge the gap between diverse chemical groups.

If there is a standard carrier for standard liquid flavors, it is Propylene Glycol (E1520). It strikes an incredibly useful balance in chemical properties.

Glycerin (E422) is often used as a “natural” alternative to PG, as it is typically derived from vegetable oils (rapeseed, soy, or palm).

When formulating for fat-based systems—like chocolate, compound coatings, bakery fillings, or oil-based savory marinades—water-miscible solvents like PG or ethanol will fail. They will not disperse into the fat phase, causing localized flavor hot spots or texture issues.

Food R&D Benchtop

For professional manufacturers, regulatory compliance is not optional. The solvents used in food flavors must adhere to strict safety standards.

In the United States, the primary regulatory framework is overseen by the FDA. Flavor ingredients, including solvents, must generally be recognized as GRAS (Generally Recognized As Safe). This designation means that the substance is considered safe by qualified experts for its intended use.

A crucial body in this arena is the Flavor and Extract Manufacturers Association (FEMA). FEMA’s expert panel conducts rigorous scientific assessments of flavor ingredients to determine their GRAS status. The “FEMA GRAS” list is the global gold standard for flavor safety assessment.

“The FEMA Expert Panel’s primary function is to evaluate the safety of flavoring substances… The Panel’s safety evaluations are conducted independently of the flavor industry and are based on the best available scientific data.” (Source: Flavor and Extract Manufacturers Association – FEMA)

When we select a solvent, we ensure it complies with relevant regional regulations, such as Regulation (EC) No 1334/2008 in the European Union, which governs flavorings for use in and on foods. We also consider dietary restrictions, ensuring Halal or Kosher compliance where necessary (e.g., avoiding ethanol for Halal, or ensure glycerin is free of animal byproducts for Kosher Pareve).

The “art” of flavor science lies in predicting how a solvent will behave in the final food matrix. Here are examples of application-specific challenges:

In a clear, sparkling beverage, the flavor must be crystal clear. If the flavor contains citrus oils (non-polar) carried in ethanol, adding it to the sugary water base can cause the oils to drop out of solution, creating a cloudy ring at the neck of the bottle known as “ringing.”

In industrial baking, internal product temperatures can exceed 95°C (203°F), and surface temperatures are much higher. A highly volatile solvent like ethanol will “flash off” rapidly during the baking process, potentially taking many volatile flavor notes with it before the product structure sets.

When flavoring dry applications like protein powders, instant beverage mixes, or snack seasonings, liquid flavors must be converted to powder. This is often done through “plating,” where the liquid flavor is sprayed onto a dry carrier like maltodextrin or salt.

In professional flavor manufacturing, solvents are never an afterthought. They are strategic tools that define the stability, efficacy, and ultimate sensory success of a flavor profile. A great flavor carried by the wrong solvent is a failed product waiting to happen.

Navigating the interplay between solubility parameters, volatility rates, processing constraints, and regulatory demands requires deep technical expertise. It requires a partner who looks beyond the aroma chemicals and considers the entire delivery system.

At our manufacturing facilities, we don’t just create tastes; we engineer flavor solutions engineered to perform reliably in your specific food

Finished Consumer Products

Are you facing challenges with flavor stability, release, or production handling in your current applications? Our team of senior flavor scientists is ready to assist. Let’s discuss how the right carrier system can elevate your product.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

| 📍 Factory Address | Room 701, Building 3, No. 16, Binzhong South Road, Daojiao Town, Dongguan City, Guangdong Province, China |

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.