Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 20, 2026

Gummy vs. Tablet Supplement Comparison

In the current era of consumer-centric medicine and proactive wellness, the “experience” of a supplement or medication has become a primary driver of adherence and brand loyalty. The industry has seen a massive migration from traditional swallowable capsules and tablets to “user-friendly” delivery systems—primarily chewable tablets and gummies. However, transitioning a formula from a flavor-neutral swallowable form to a chewable one is not merely a task of adding “grape” or “cherry” aroma. It is a fundamental engineering challenge that requires an intimate understanding of food chemistry, material science, and sensory physiology.

As professional manufacturers of food and beverage flavorings, we recognize that the flavor system is often the most volatile and reactive component of a chewable formulation. It interacts with gelling agents, influences the plasticity of polymers, and must compete with the aggressive, often aversive sensory profiles of active pharmaceutical ingredients (APIs) and botanical extracts.

This article serves as a deep technical dive into the strategies required to flavor these complex delivery systems, focusing on overcoming the dual challenges of physical texture degradation and inconsistent flavor release.

The “gummy” is no longer just a confectionery item; it is a sophisticated hydrogel delivery system. The primary gelling agents used today—Gelatin, Pectin, and various starches—each possess unique chemical properties that dictate how flavor molecules are trapped and subsequently released.

Gelatin remains a favorite for its unparalleled mouthfeel. Derived from collagen, it forms a triple-helix structure that is thermoreversible. From a flavoring perspective, gelatin’s most significant attribute is its melting point, which typically sits between 32°C and 35°C, just below human body temperature.

However, gelatin is highly reactive. One of the most common issues is cross-linking. When gelatin interacts with certain active ingredients (especially those high in polyphenols, like green tea extract or grape seed extract) or certain aldehydes found in flavors, the protein chains form covalent bonds.

Pectin, specifically High-Methoxy (HM) Pectin, is the industry standard for vegan gummies. Unlike gelatin, pectin gels through a combination of low pH and high sugar solids.

For formulations requiring higher heat stability (for shipping in tropical climates), carrageenan or agar-agar are often used. These polysaccharides create very rigid gels. The technical hurdle here is that these gels do not melt in the mouth; they rely purely on mechanical mastication for flavor release. This necessitates a much higher “top-note” flavor load to ensure the aroma reaches the olfactory receptors before the product is swallowed.

Chewable tablets present a different set of physical constraints. Here, the “matrix” is a compressed bed of granules. The flavoring system must survive the mechanical stress of compression and then perform during the brief window of chewing.

During the tableting process, compression forces can exceed 20 kN. If a flavor is applied as a simple liquid spray onto the granulation, the pressure can force the flavor oils into the pores of the excipients (like mannitol or xylitol), “burying” the flavor and preventing it from being sensed during chewing.

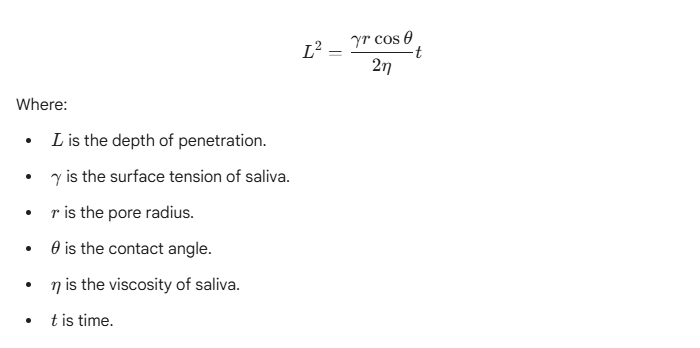

The rate of flavor release in a tablet is governed by how quickly saliva can penetrate the tablet. We utilize the Washburn Equation to model this penetration:

If a flavor system is too hydrophobic (oil-based), it increases the contact angle (η), effectively waterproofing the tablet and delaying both the flavor release and the dissolution of the active ingredient.

In any chewable form, the “flavor” is not a static attribute but a kinetic event. We analyze flavor release through the lens of Time-Intensity (T-I) Profiling.

For a gelatin gummy, the release of a flavor molecule can be approximated by a modified Higuchi Model, which suggests that the amount of flavor released (Q) is proportional to the square root of time:

Where K is a constant incorporating the diffusivity of the flavor molecule and its solubility in the matrix. Our R&D team works to optimize K by selecting the correct flavor carriers (e.g., MCT oil vs. Triacetin) to ensure the release curve doesn’t peak too early or too late.

The most significant technical hurdle in flavoring chewables is the presence of bitter APIs or botanical extracts. Traditional sweeteners (Sucrose, Stevia, Monk Fruit) are rarely enough. We employ a “Layered Masking” strategy.

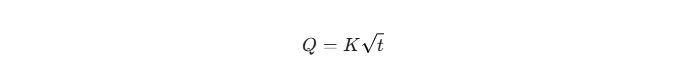

Cyclodextrins are cyclic oligosaccharides with a “donut” shape. The hydrophobic interior can “host” a bitter molecule, physically preventing it from binding to the bitter receptors (TAS2Rs) on the tongue.

According to a study published by the Journal of Pharmaceutical Sciences, the use of β-cyclodextrin can reduce the perceived bitterness of compounds like ibuprofen or caffeine by up to 70% without affecting the drug’s bioavailability. (Citation 1).

We utilize specific “bitter blockers”—compounds that have no flavor of their own but bind to the T2R receptors, effectively “turning them off” for the duration of the chewing process. Common natural blockers include specific derivatives of mushroom extracts or certain flavonoids that target a wide spectrum of the 25 known human bitter receptors.

The brain’s perception of taste is heavily influenced by other sensations.

Bitter Blocker Mechanism Diagram

One of the most common failures in the market is a product that tastes great at launch but becomes unpalatable after three months on the shelf.

Citrus flavors (Lemon, Orange, Lime) are dominated by Limonene, which is highly prone to oxidation. In the presence of the moisture and heat used in gummy manufacturing, Limonene breaks down into Carvone and Limonene Oxide, which smell like turpentine or “stale” mint.

In gummies, the water activity must be carefully balanced (aw ≈ 0.60 – 0.65). If the aw is too high, the flavor molecules will migrate from the center of the gummy to the surface and evaporate. If it’s too low, the gummy becomes hard.

According to the Association of Food and Drug Officials (AFDO), maintaining precise water activity is not just a safety requirement but a critical factor in maintaining the organoleptic stability of functional foods. (Citation 2).

In chewable tablets containing proteins (like collagen) and reducing sugars (like lactose), the Maillard reaction can occur during storage. This not only turns the tablet brown but produces “toasted” or “burnt” flavors that may clash with intended fruit profiles. Our flavorists counteract this by selecting non-reducing sugars (like Sucralose or Erythritol) and using “Masking Flavors” that harmonize with browning notes.

Gummy Stability Comparison

Scaling a flavor from a 1kg benchtop sample to a 500kg production batch introduces several “thermal” and “mechanical” variables.

In gummy production, the “cooked” slurry is often held at temperatures between 90°C and 110°C. If flavor is added too early in the mixing tank, the high-volatile “top notes” will literally evaporate out of the kettle—a phenomenon known as “flash-off.”

The Pet Food Institute (which often leads research in animal “chewable” palatants that mirrors human technology) notes that the mechanical shear during the extrusion or molding of chewables can significantly alter the “volatilization” of the flavor system. (Citation 3).

The “congruency” of a flavor is a psychological tool. If you have a bitter ingredient, don’t try to hide it with a “light” flavor like Watermelon.

| Active Ingredient | Common Off-Note | Recommended Flavor Profile |

| Omega-3 (Fish Oil) | Fishy, Oxidized | Intense Citrus (Lemon/Lime), Ginger, or Mint |

| B-Vitamins | Sulfurous, “Yeasty” | Tropical Fruits (Mango, Passionfruit), Berries |

| Iron | Metallic, Blood-like | Chocolate, Grape, or “Dark” Berries |

| Valerian Root | “Dirty Socks,” Earthy | Honey, Toffee, or Spiced Apple |

| Hemp/CBD | Grassy, Nutty | Mint, Chocolate, or Citrus-Pine |

The National Center for Complementary and Integrative Health (NCCIH) emphasizes that for botanical supplements, the sensory profile is the primary factor in consumer “compliance”—if the product tastes “natural but not dirty,” consumers are more likely to finish the bottle. (Citation 4).

| Problem | Potential Root Cause | Technical Solution |

| Gummies are too sticky | High Propylene Glycol (PG) in flavor | Switch to an MCT-based or Glycerin-based flavor carrier. |

| Tablets have “spots” | Flavor oil migration/Oxidation | Use micro-encapsulated “Dry” flavor powders instead of liquids. |

| Flavor disappears after 1 month | High Water Activity (aw) | Reformulate the hydrocolloid ratio to lock in moisture; use barrier coating. |

| Metallic aftertaste | Ionized minerals | Incorporate a “Chelating Flavor” or specific metallic-masking modulator. |

| Gummy “Snaps” instead of Chews | Gelatin cross-linking | Add a “Cross-linking Inhibitor” (e.g., specific organic acids) to the flavor system. |

As the market for chewable tablets and gummies continues to expand into complex pharmaceutical applications—including “Gummy-Tech” for personalized medicine and 3D-printed chewables—the role of the flavor scientist has moved to the center of the R&D process.

Success in this field requires more than just a library of aromas. It requires a partner who understands the thermodynamics of gelling, the kinetics of release, and the molecular biology of taste. By bridging the gap between clinical efficacy and culinary delight, we ensure that the next generation of health products is not just effective, but enjoyable.

Healthy Lifestyle Supplement Routine

Are you currently struggling with a “bitter” botanical or a “rubbery” gummy matrix? Our technical R&D team is ready to help you engineer a solution that wins on both science and taste.

Would you like to request a technical consultation with our flavor chemists, or shall we send you a “Masking Kit” containing our latest bitterness-blocking and texture-neutralizing samples?

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.cn |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Citations:

Copyright © 2025 Guangdong Unique Flavor Co., Ltd. All Rights Reserved.